Securing luggage efficiently prevents damage and theft during transit. Our airport-grade solutions tackle these pain points effectively.

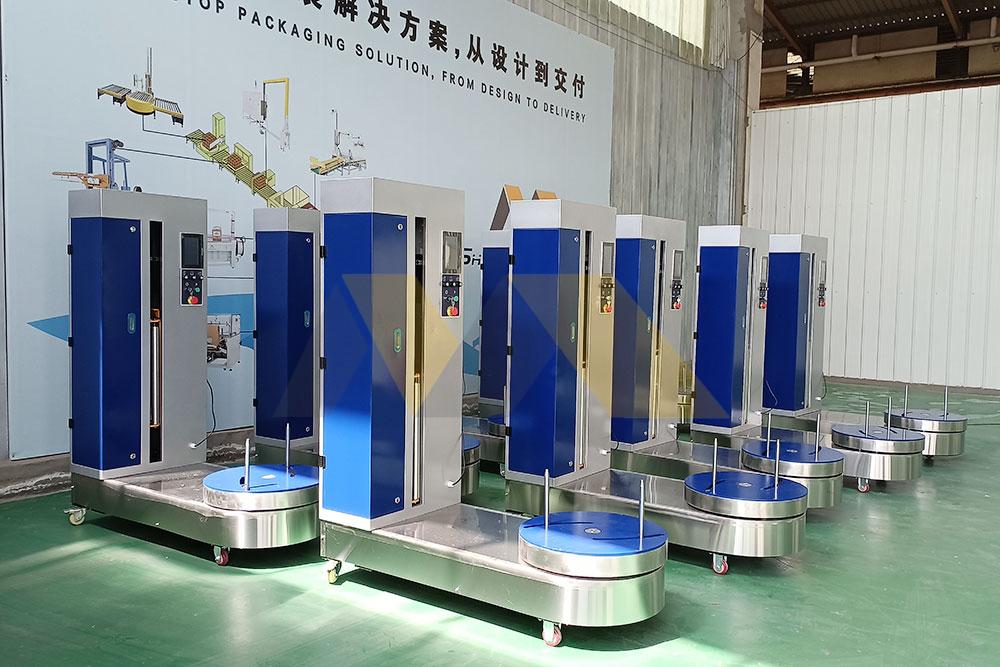

Airport baggage wrapping machines strengthen suitcases with industrial film, protecting contents from tampering, weather, and mishandling during flights while streamlining check-in operations for faster passenger processing.

Modern airports demand reliable protection systems as baggage volumes surge annually. I’ve seen how damaged luggage creates passenger frustration and compensation costs. This drives our focus on developing robust solutions.

What Makes Automatic Luggage Wrapping Machines Essential?

Manual wrapping strains staff and slows queues. Automatic models handle 500+ bags/hour consistently, reducing labor headaches.

Automatic luggage wrapping machines self-adjust film tension, detect bag sizes, and seal without operator intervention, guaranteeing uniform protection while cutting staffing needs by 60% vs manual methods.

Key Operational Advantages

Our Chinese factory customizes machines for specific airport workflows:

-

Speed optimization

Integrated sensors measure baggage dimensions in <2 seconds, eliminating manual adjustments -

Failure prevention

Dual motor systems maintain operation if one fails -

Material efficiency

Smart tension control reduces film waste by 30%

| Feature | Standard Model | Heavy-Duty Model |

|---|---|---|

| Bags/Hour Capacity | 550 | 800 |

| Max Bag Weight | 32kg | 50kg |

| Film Usage/Bag | 2.8m | 3.2m |

| Power Recovery | Partial | Full backup |

Heavy-traffic airports like Singapore’s Changi need such reliability. One operator can manage three units simultaneously, with real-time jam alerts via touchscreen. When your current system causes delays, message us directly for throughput analysis. We configure machines to integrate with existing conveyor layouts.

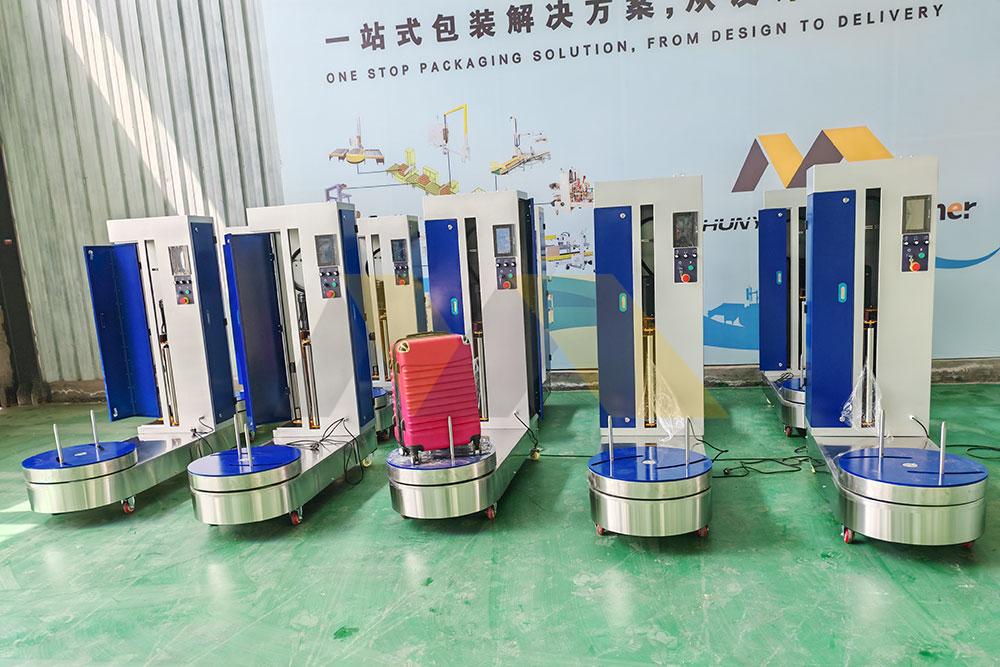

Why Choose Portable Luggage Wrapping Machines?

Fixed systems struggle with seasonal rush zones. Mobile units solve space-limited pain points flexibly.

Portable luggage wrapping machines deploy in 10 minutes, operate at security checkpoints or overflow areas, and handle irregularly sized items like golf bags that conventional systems reject.

Deployment Scenarios and Benefits

Having supplied Japanese train stations, I know compact solutions beat rigid installations:

-

Temporary checkpoint setups

Wheels and folding design enable repositioning during peak hours -

Oversized baggage handling

Adjustable arms wrap skis/equipment cases (up to 1.5m height) -

Backup during maintenance

Seamlessly replaces downed mainline units

Maintenance Tip: Our modular components allow swapping motors in 15 minutes without technicians. We also provide waterproof covers for outdoor festivals. Request sample deployment videos on WhatsApp to see flexibility before purchasing.

What Determines Luggage Wrapping Machine Prices?

Base models cost $3,000-$7,000 USD, while premium automation reaches $28,000. I explain variations transparently.

Luggage wrapping machine prices vary by automation level (manual/semi/fully-auto), film capacity, production volume tolerance, and added features like thermal sealing or RFID tagging systems.

Price Optimization Strategies

Avoid overpayment with these insights from our North American clients:

-

Film consumption analysis

Calculate daily wrap volumes to avoid oversized motors -

Modular upgrades

Start semi-auto, add automation later -

Certification costs

CE/ISO marks add 8-12% but simplify EU exports

Hidden Cost Alert: Cheap motors fail at 100,000 cycles vs our 500,000-cycle guarantee. See our maintenance cost calculator to compare 5-year ownership expenses.

Can Airports Reduce Luggage Wrapping Machine Costs?

Yes, with volume discounts and localization strategies we employ globally.

Airport luggage wrapping machine costs lower through bulk procurements (>10 units), local assembly hubs eliminating import duties, and multi-year maintenance bundles that cover spare parts.

Cost-Saving Implementation Map

Japan Airlines saved 40% with our approach:

| Strategy | Savings % | Implementation Time |

|---|---|---|

| Customs-Free Assembly | 22% | 3 months |

| Modular Spare Kits | 15% | Immediate |

| Energy Recovery Systems | 18% | 30 days |

We establish regional assembly near your hubs to dodge tariffs. Our Vietnam facility serves ASEAN clients duty-free while maintaining Chinese quality control. Send your airport specs via WhatsApp for customized financial modeling.

Conclusion

Advanced wrapping solutions balance security, efficiency and cost – a necessity for modern airports.