Seeing shipments collapse during transit frustrates buyers daily. I help distributors prevent this with machines that cut labor costs while stabilizing loads through proper wrapping.

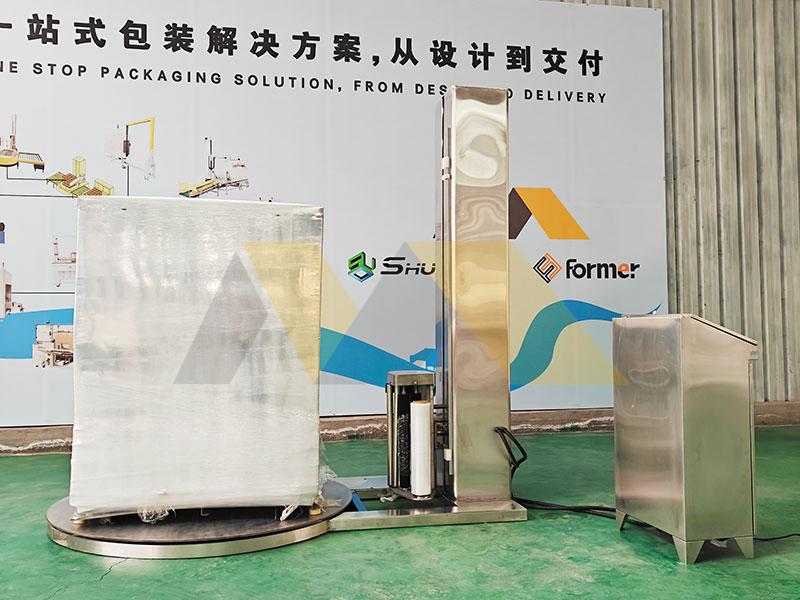

A semi-automatic pallet wrapper is rotational machinery securing goods using stretch film through operator-loaded pallets and programmable tension control, balancing human oversight and mechanized consistency at affordable price points.

With 7 years exporting machines globally, I’ll decode wrapper classifications and terminology for buyers exploring cost-effective stabilization solutions. Let’s examine key types and features impacting your operations.

What are the different types of pallet wrappers?

Picture workers straining to rotate heavy pallets manually. Fatigue causes uneven tension. This is avoidable with mechanized options matching throughput needs.

Pallet wrappers include manual turntables (human-powered), semi-automatic (operator-assisted), automatic (conveyor-integrated), and robotic arms (fully autonomous), targeting varying pallet volumes and automation requirements.

Choosing wrong machinery drains budgets. Through installing systems across North America, I categorize them by functional advantages:

Throughput-Load Compatibility Matrix1

| Type | Max Pallets/Hr | Ideal Facility Size |

|---|---|---|

| Manual | 10-15 | Small workshops (<50 pallets/day) |

| Semi-Auto | 20-40 | Mid-sized warehouses |

| Automatic | 60-90 | Distribution centers |

| Robotic | 100+ | High-volume logistics hubs |

A Japanese importer switched from manual to our semi-auto models2 last year, doubling output without hiring extra staff. Verify your daily volume against machine capacity—email pallet dimensions/work hours to [email protected] for compatibility analysis. Undersized equipment creates bottlenecks while oversized versions waste capital.

What is the difference between semi automatic and automatic stretch wrappers?

Watching operators wait between cycles signals inefficiency. Automatic wrappers solve this but cost more upfront. Semi-auto systems offer balanced solutions.

Semi-automatic wrappers need operators to place/unload pallets whereas automatics integrate conveyor lines managing continuous in/out flows autonomously, with auto systems costing 65-120% more but handling higher volumes.

Understanding workflow integration3 prevents overspending:

Cost vs Function Breakdown

| Factor | Semi-Automatic | Automatic |

|---|---|---|

| Operator Role | Pallet handling + cycle start | Minimal oversight |

| Integration | Standalone | Conveyors/warehouse control systems |

| Avg Investment | $3,500-$9,000 | $12,000-$25,000 |

| ROI Period | 8-14 months | 18-24 months |

Our Singapore client saved 55% versus automation quotes by opting for semi-auto units that managed his daily 30-pallet requirement. Not every space needs full automation—share warehouse layouts via contact form for space optimization tips. Testing confirms semi-automatic models satisfy 70% of mid-volume facilities when sized correctly.

What is a pallet wrapper?

Imagine unsecured boxes sliding off trucks during transit. Pallet wrappers prevent such costly damage via systematic stabilization processes.

Pallet wrappers are industrial machines stabilizing loads by rotating pallets while applying engineered stretch film layers that create uniform containment pressure, replacing inconsistent manual labor with measurable load integrity.

These systems deliver reliability through deliberate engineering:

Key Subsystems and Functions

| Component | Function | Performance Impact |

|---|---|---|

| Turntable | Rotates pallet for 360° coverage | RPM adjustment prevents top-heavy loads tipping |

| Film Carriage | Guides film roll during wrapping | Height sensing ensures consistent overlap |

| Tensioner | Controls film stretch ratio | Eliminates film breaks and slack |

| Control Panel | Stores wrapping programs | One-touch recall for different pallet types |

A Canadian distributor reduced product damage claims by 40% after implementing programmable pre-stretch settings on our wrappers. Verify if machinery includes customizable protocols4—send your pallet photos via WhatsApp 0086 13505379893 for free profiling templates.

Is stretch wrap the same as pallet wrap?

Discovering torn film after shipping causes frustrating losses. Using "stretch wrap5" interchangeably ignores material differences impacting performance.

Stretch wrap refers specifically to polyethylene film with elastic properties whereas pallet wrap denotes its function – both describe the same product. Compatibility depends on machine settings matching film thickness and cling additives.

Film functionality varies by application environment:

Film Properties Selection Guide

| Feature | Manual Use Film | Machine-Optimized Film |

|---|---|---|

| Core Size | 1.5-3 inch | 3 inch (fits machine dispensers) |

| Thickness | 15-17 microns | 20-23 microns |

| Pre-Stretch Ability | Basic elasticity | Engineered for 250-300% stretch |

| Enhanced Properties | Standard cling | UV protection plus anti-tear coating |

Using incompatible film voids warranty claims. Last winter we assisted a logistics firm whose winter-grade shipments failed when using summer film. Always match specifications—forward temperature operating ranges to [email protected] for film grade recommendations.

Conclusion

Semi-automatic wrappers6 optimize cost and efficiency, differentiating themselves from manual and automatic variants while requiring compatible pallet wrap for peak performance.

-

Understand how this matrix can help you choose the right pallet wrapper for your needs. ↩

-

Learn how semi-auto models can double your output without increasing labor costs. ↩

-

Discover the importance of workflow integration in optimizing your pallet wrapping process. ↩

-

Explore how customizable protocols can improve the efficiency and effectiveness of your wrapping machines. ↩

-

Clarify the distinctions between stretch wrap and pallet wrap to ensure optimal usage. ↩

-

Find out how automatic wrappers can streamline your packaging operations and save time. ↩