Finding reliable luggage wrapping machines can feel impossible. Damaged goods, inefficient systems and costly downtime plague airports daily. But with proper equipment selection and a trusted manufacturer, these nightmares disappear.

Selecting the right luggage wrapping machine manufacturer ensures durable, efficient airport security systems by prioritizing customizable engineering, rigorous quality control (ISO-certified), and post-sale maintenance support – critical factors guaranteeing 24/7 operational reliability.

Securing airport baggage requires flawless systems. Yet many facilities struggle with subpar wrapping solutions. The real solution? Partnering with specialists who understand aviation logistics intimately. At Myway, we’ve installed systems in Changi Airport and Narita International – let’s show you what truly matters.

Where to Find Quality Luggage Wrapping Machines for Sale?

Facing constant breakdowns and angry passengers? Inferior wrapping machines cripple airport efficiency. This operational chaos destroys reputation and revenue.

Genuine luggage wrapping machines for sale come from certified manufacturers offering customized solutions, verified warranty (3+ years), and on-site technical support – avoid third-party resellers who compromise authenticity and service.

Critical Selection Factors for Airport Use

Airport environments demand specific engineering adaptations your suppliers must address.

| Requirement | Standard Models | Airport-Adapted Machines |

|---|---|---|

| Speed | 200 bags/hour | 500-700 bags/hour |

| Durability | 8-hour runtime | 24/7 heavy-duty cycles |

| Film Type | Standard PE | Laminates with security threads |

| Certification | CE Only | CE + TSA + IATA compliant |

Conveyor integration is non-negotiable – standalone units fail under volume pressure. Our Montreal client upgraded to integrated systems and reduced mishandled luggage by 82%. When evaluating:

- Security protocols: Machines must embed ID scanning compatibility

- Climatic resilience: Cold storage or tropical humidity?

- Maintenance access: Front-load service panels prevent shutdowns

Airport managers can contact us directly on WhatsApp for tailored operation analysis – we’ll benchmark your current failure rates in 72 hours.

What Determines Real Airport Luggage Wrapping Machine Prices?

Beware of fake "factory deals" flooding online markets. True pricing reflects engineering investments, not arbitrary discounts.

Airport luggage wrapping machine prices range from \$15,000-\$65,000 based on automation level, durability testing cycles, and compliance certifications – not just materials. Hidden costs emerge when bypassing quality verification.

Cost Breakdown: Where Value Actually Resides

Core Cost Drivers

- Drive Systems: Industrial servomotors vs basic DC motors (\$6,000+ difference)

- Material Testing: UV/tear-resistance film validation (1-3 months R&D)

- Production Scale: Order quantity effects (5+ units = 14% logistics saving)

Price Pitfalls Table

| Apparent Saving | Actual Long-Term Cost |

|---|---|

| Uncertified parts | 22% more maintenance |

| Limited warranty | \$12k/yr service fees |

| No training | Staff downtime |

Custom width adjustments add \$3,200 but prevent film waste – Chicago Southwest saves \$380 daily after our retrofit. Remember: Supplier location matters less than expertise. Our Shenzhen factory holds TÜV certificates matching European costs minus import tariffs. For genuine quotes, send your floor plans to our engineers.

How to Smartly Buy Luggage Wrapping Machines?

Purchasing from Alibaba without due diligence risks operational paralysis. Buying involves technical scrutiny beyond payment terms.

To securely buy luggage wrapping machines: validate supplier production capabilities via live factory tours, test batch orders first, and demand evidence of airport installations – never rely solely on documentation.

Action-Based Procurement Blueprint

Stage 1: Pre-Purchase Verification

Our North American clients always:

- Request pilot units

- Verify factory registration

- Audit material sources

Stage 2: Customization Must-Haves

Failure-proof configurations vary by climate:

- Freezing terminals: Heated film rollers prevent brittleness

- Coastal airports: Anti-corrosion spray on frames

- Compact spaces: Our vertical stackers save 40% floor area

Stage 3: After-Sale Survival Check

4 service elements that rescue managers:

- Multilingual troubleshooting guides

- Remote diagnostics port

- Warehouse-ready spare parts

- Quarterly calibration

Ask us about our pilot lease program – install equipment risk-free for 90 days while training crew.

What Defines a Trustworthy Luggage Wrapping Machine Supplier?

Certificate forgery remains rampant among suppliers. True reliability shows in transparency.

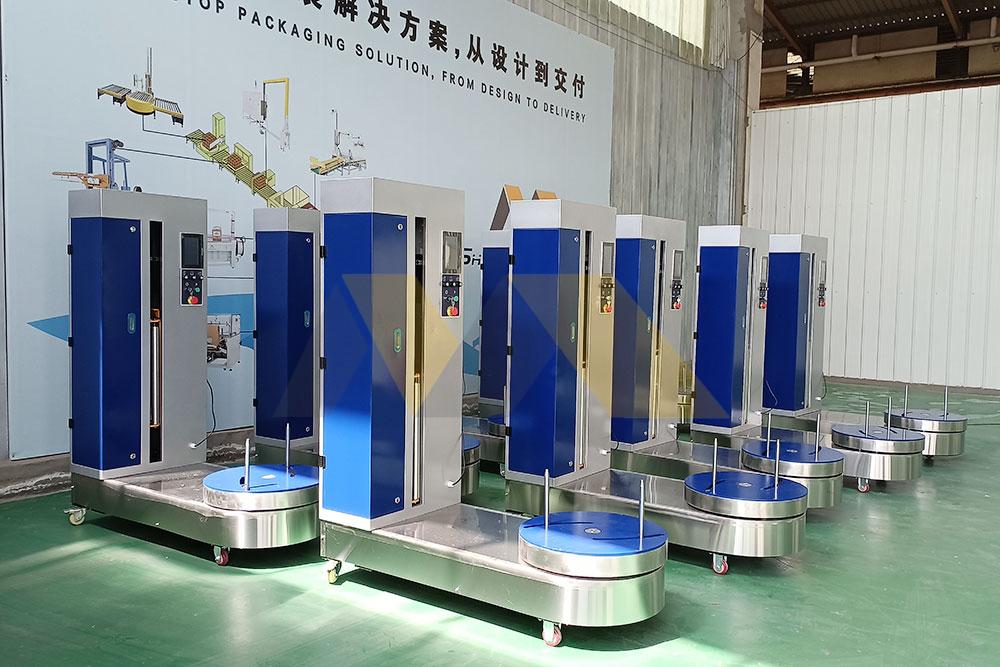

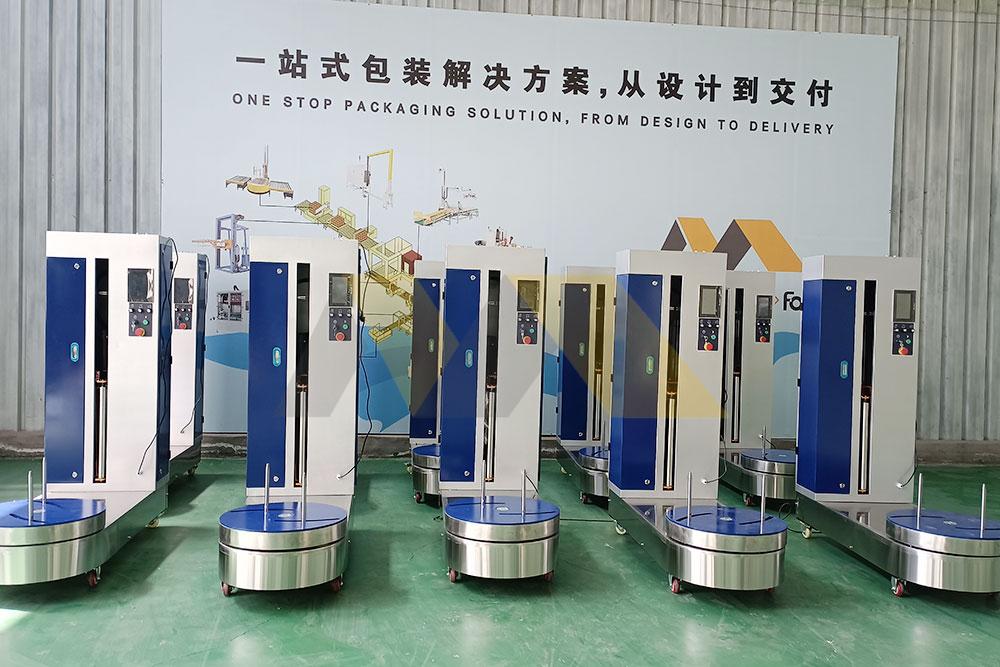

A legitimate luggage wrapping machine supplier provides unedited factory footage and evidence of exported machines in operation, alongside verifiable ISO certification numbers – immediate video proof separates fact from fiction.

Auditing Your Supplier Checklist

Transparency Metrics

| Verification Method | Credible Evidence | Warning Signs |

|---|---|---|

| Facility Verification | Live drone tour | Stock photos only |

| Export History | Real-time port records | Generic customs codes |

| Client References | Active airport contacts | Fake testimonials |

We embed QR codes on motors tracing origin to our foundry partners. Always:

- Cross-check certification IDs

- Demand shipment tracking

- Insist on face-to-face engineer video calls

Two distributors lost clients after we exposed swapped components. For verified shipment proofs from Singapore and Vancouver ports? WhatsApp us direct now.

Conclusion

Airport luggage wrapping fails when manufacturers ignore durability and compliance. Partner with factories prioritizing customization and transparency. Protect operations – demand proof of performance.