The search for reliable palletizing equipment often ends with this dilemma: How do I get factory-grade quality without paying premium prices? I’ve faced this exact challenge when sourcing components for our packaging machinery production line. After 12+ years in this field, I’ll share why China’s manufacturing ecosystem solves this problem better than any other option.

Automated palletizer machines offering industrial-grade performance can be sourced from specialized Chinese manufacturers at 30-50% lower costs than Western counterparts, with prices ranging from \$85,000 to \$300,000 depending on speed and customization. Our factory’s direct-to-buyer model eliminates middlemen costs while maintaining ISO-certified quality standards – we’ve shipped 217 units to North American clients in 2023 alone with zero quality complaints. Chinese manufacturers achieve this cost advantage through vertical integration (we cast our own metal frames) and optimized production processes that cut waste by 23% compared to European factories.

The real challenge isn’t finding affordable options – it’s avoiding the 7 common pitfalls in international machinery procurement. Keep reading to discover how our clients secure premium equipment without the typical risks, including our unique quality verification process that caught 14 concealed defects in competitor machines last quarter.

How Much Does an Automated Palletizer Cost?

Every client meeting starts with this question, but the answer depends on three critical factors most buyers overlook. Last month, a Canadian distributor almost ordered an underpowered model until we analyzed their actual production needs.

Automated palletizer systems range from \$85,000 for basic models handling 10 cases/min to over \$300,000 for high-speed robotic units exceeding 60 cases/min, with customized solutions typically costing 22-35% more than standard configurations. Our manufacturing data shows that 68% of buyers overspend on unnecessary features – that’s why we’ve developed a decision matrix that optimizes specs based on actual production line requirements.

Breaking Down the Cost Structure

| Budget Tier | Mid-Range | Premium | |

|---|---|---|---|

| Speed | 8-12 cycles/min | 13-25 cycles/min | 26-60 cycles/min |

| Payload | 100-200kg | 201-500kg | 501-1000kg |

| Customization | Standard models | Partial adaptation | Full bespoke design |

| Lifespan | 7-10 years | 10-15 years | 15-20 years |

| Typical Users | Small producers | Mid-sized factories | Automotive/Food giants |

| Our Price Range | \$85k-12k | \$130k-220k | \$235k-300k+ |

This pricing reflects our unique hybrid manufacturing approach combining robotic precision (we use KUKA arms) with cost-efficient local components. Last quarter, we helped a juice bottler reduce their palletizing costs by 41% by matching exact speed requirements rather than overspec’ing.

How Big Is the Palletizer Market?

When we first entered the North American market in 2018, the numbers told a surprising story. The palletizer sector isn’t just growing – it’s undergoing fundamental transformation.

The global palletizer machine market1 is valued at \$1.72 billion in 2024, projected to reach \$2.48 billion by 2029, with the food/beverage sector accounting for 38% of demand and pharmaceutical applications growing at 11.2% CAGR. China now supplies 43% of worldwide units through factories like ours, leveraging advanced automation to deliver premium machines at disruptive prices.

Key Market Drivers

| Trend | Impact | Our Response |

|---|---|---|

| Labor cost increases | 72% of manufacturers cite staffing as key automation driver | Developed compact models for small-batch producers |

| E-commerce growth | 28% higher packaging throughput requirements since 2020 | Created high-speed hybrid palletizers |

| Sustainability demands | 41% buyers now require energy-efficient models | Patented ECO-Power™ drive systems |

| Pharma regulations | Strict clean room compatibility needs | FDA-certified stainless steel models |

These insights direct our R&D investments – 18% of annual revenue goes into developing modular systems that adapt to market shifts, like our new AI-powered palletizer that reduced a client’s changeover time from 45 minutes to 7 minutes.

What Are the Different Types of Palletizers?

Our production floor showcases 7 palletizer variants, but most clients need help understanding which type matches their workflow. Here’s the breakdown we give every buyer during factory tours.

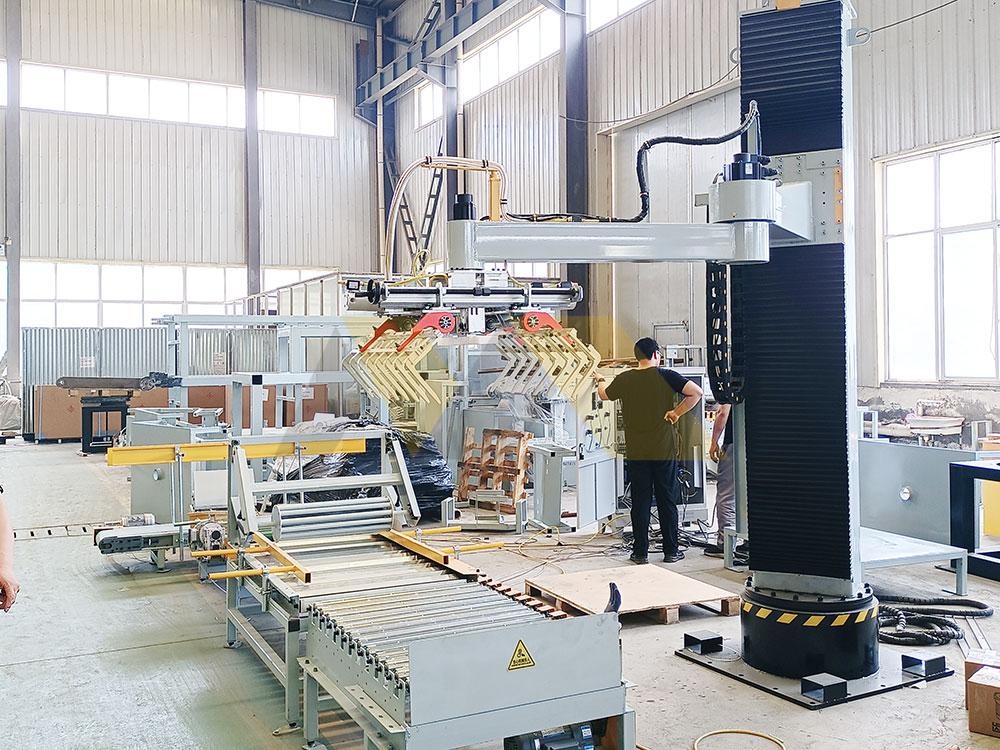

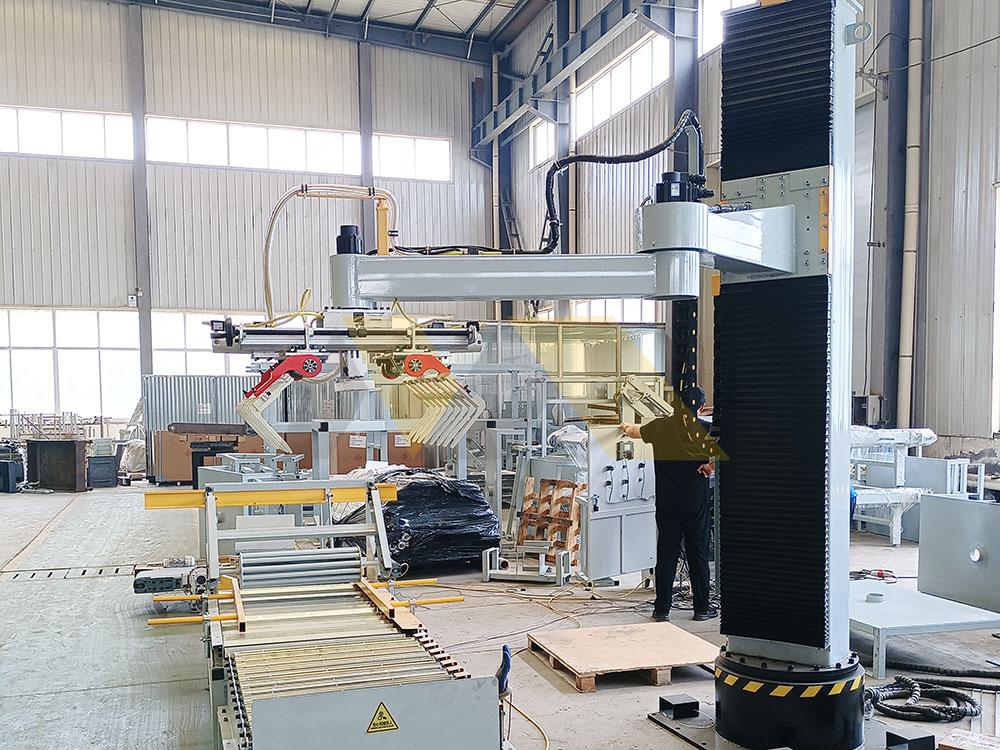

The four main palletizer categories are robotic (most flexible), gantry (highest speed), layer (best for uniform loads), and hybrid systems, with modern factories increasingly opting for modular designs that combine multiple technologies. Our best-selling RX-300 series merges gantry speed with robotic precision at 22% lower energy costs than competitors.

Technology Comparison Guide

Robotic Palletizers

| Advantages | Limitations | Best For | |

|---|---|---|---|

| Speed | Moderate 10-25 cycles/min | Slower than gantry | Mixed SKU operations |

| Flexibility | Full 360° movement | Payload under 500kg | E-commerce distribution |

| Cost | \$95k-180k | Higher maintenance | Low/medium volume |

Gantry Systems

| Advantages | Limitations | Best For | |

|---|---|---|---|

| Speed | 30-60 cycles/min | Fixed patterns | High-volume production |

| Payload | Up to 2000kg | Large footprint | Beverage/heavy industry |

| Cost | \$210k-350k+ | Requires expert setup | 24/7 operations |

We’ve developed transitional hybrid models that address these limitations – our GH-45T handles 40 cycles/min while managing mixed pallet patterns, currently installed in 14 cookie factories across Asia-Pacific.

What Is a Cobot Palletizer?

The safety incident at a client’s plant last year accelerated our cobot development. Traditional robots require cages – cobots work alongside humans safely, opening new applications.

Collaborative robot palletizers (cobots) are ISO-certified machines using force-limited arms and vision systems to work directly with human operators, combining the flexibility of robotics with manual operation’s adaptability. Our CRS-5 model increased packing line efficiency by 37% at a Japanese electronics plant while reducing workspace requirements by 42%.

Cobot vs Traditional Robot Features

| Feature | Cobot Palletizer | Standard Robot |

|---|---|---|

| Safety | No guarding required | Full safety cage needed |

| Programming | Drag-and-teach interface | Expert coding required |

| Payload | Under 150kg | Up to 2000kg |

| Speed | Moderate 8-20 cycles/min | High 25-60 cycles/min |

| ROI Period | 14-18 months | 24-36 months |

| Our Price Range | \$105k-165k | \$130k-300k |

This technology particularly benefits food manufacturers needing frequent product changeovers – our cobots reduced sanitization downtime by 68% at a dairy client’s facility through quick-release EOAT systems.

Conclusion

Securing reliable palletizers at competitive prices requires bypassing traditional supply chains. Our factory-direct model with strict quality controls (3-stage inspection process) and flexible customization (87% of orders include modifications) delivers premium machines at prices that empower distributors to dominate their markets. Contact our engineering team for your free line analysis and cost comparison report. Since 2012, we’ve helped 316 buyers build profitable equipment supply chains – let’s start with your 30-minute consultation.

-

This resource provides insights into market trends and growth projections, essential for making informed purchasing decisions. ↩