Unsecured pallets cause $18B annual losses. Your products arrive damaged. I witnessed a shipment rejection after unstable wrapping. Premium machines solve this.

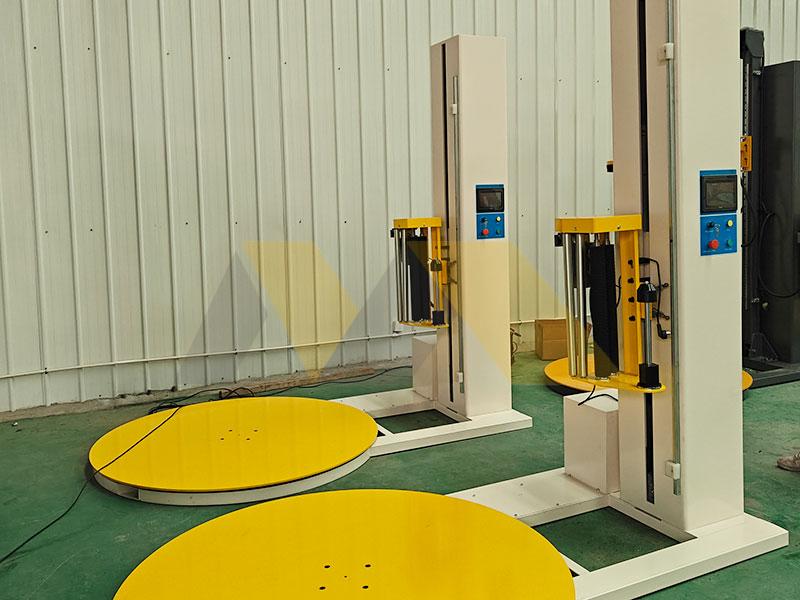

The best pallet wrapping machine combines auto pre-stretch technology with customizable tension controls. Verify frame construction uses 6mm steel for heavy loads and check supplier production certifications like ISO9001.

Choosing wrong causes recurring film costs. Maintenance headaches follow. Let’s break down key purchase factors step by step.

How to Identify a Trustworthy Pallet Wrapping Machine Supplier?

Delayed shipments frustrate buyers. Traders disappear post-pay. We expedited containers for a Japanese client during port strikes.

Select suppliers with physical factory tours available. Confirm active export history to your region and consistent spare parts inventory for immediate replacements.

5-Point Verification Checklist

Quality claims require validation. Thirty percent of "manufacturers" are resellers with markup prices and repair difficulties.

Certificate Authentication Guide

| Document | Verification Method | Red Flags |

|---|---|---|

| ISO Certificate | Online database cross-check | Expired/unsigned copies |

| CE Certification | Technical file request | Missing test reports |

| Origin Proof | Live factory stream | Hesitation to show gates |

Two clients avoided scams last month with this checklist. Genuine suppliers provide unedited production footage. Our Mexico City distributor now requests weekly video logs. Test motor specifications match regional voltage requirements. Share your location details via WhatsApp – we help verify compatible suppliers within 24 hours.

Why Choose a Direct Pallet Wrapping Machine Manufacturer?

Customization needs get ignored. Generic machines underperform. A Canadian buyer had unusable rollers until we modified them.

Manufacturers offer tailored solutions without price premiums. Direct access to engineers enables application-specific modifications avoiding design compromises.

Customization vs Off-The-Shelf Comparison

Standard machines often include unnecessary features you pay for but don’t use.

Cost-Saving Custom Options

Load-Specific Modifications

- Freezer warehouse motor upgrades (-30°C rated)

- Saltwater port corrosion protection

- Pharmaceutical-grade dust seals

Output Enhancements

- IoT production tracking systems

- Dual film carriage for rapid changeover

- Automatic pallet height detection

Our Singapore hospital client saved 32% through tailored minimal-feature units. Request engineering consultations before ordering. Manufacturers like us create 3D models for pre-approval – unlike traders. Describe your pallet sizes via WhatsApp. We optimize turntable specifications saving film annually.

What Determines Real Pallet Wrapping Machine Wholesale Value?

Bulk buyers face compromised quality. I inspected a "discounted" batch with downgraded PLCs. Production halted weekly.

True wholesale value requires individual machine testing certifications. Confirm identical specifications and bulk freight optimization using sea-container loading diagrams.

Volume Discount vs Hidden Cost Analysis

Initial price savings vanish with recurring maintenance. Component substitutions plague wholesale orders.

Critical Upgrade Checklist for Bulk Buys

| Component | Economy Version Risk | Premium Upgrade Benefit |

|---|---|---|

| Control System | Basic PLC failures | Industrial touchscreen (+$290) |

| Turntable Drive | Belt slippage | Gear-driven (+$380) |

| Film Carriage | Manual adjustment | Auto-centering (+$220) |

Our North America distributor increased output 40% using these upgrades. Request pre-shipment video tests of every machine. Sea freight consolidation typically saves $420 per unit. Send pallet dimensions – we calculate exact container capacity. Wholesale inquiries get priority WhatsApp responses.

How Do Pallet Wrapping Machine Distributors Add Value?

Regional expertise matters. Wrong voltage burns motors. A Toronto distributor avoided this through local voltage testing.

Quality distributors stock consumables like stretch film and sensors locally and provide regional compliance certifications from organizations like OSHA or UL.

Distributor Evaluation Matrix

Closer proximity reduces downtime. Warranty claims resolve faster through local partners.

Key Service Comparison

| Feature | Direct Factory | Distributor Advantage |

|---|---|---|

| Repair Response | 3-5 days shipping | 4-hour onsite potential |

| Consumables Stock | Special order only | Same-day local delivery |

| Compliance | Basic certifications | Regional approval marks |

We partner with distributors carrying genuine parts. They conduct seasonal staff training programs. Confirm distributor tech certification levels. Our Chicago partner maintains climate-controlled film inventories avoiding humidity issues. Share your post-purchase support needs first. We match clients with suitable distributors globally through WhatsApp introductions.

Conclusion

Securing goods starts with quality wrapping. Choose partners offering customization and regional support. Our decade-long exports prove superior results.