Damaged goods drain profits every shipment. Unreliable machines create bottlenecks at the busiest hours. Our 2023 client survey showed 73% reduced claims after switching to specialized systems.

Top performance horizontal wrapping machines require application-specific designs, durability-proven components, and supplier transparency—we provide ISO 9001 certified custom machines tested at 12,000 cycles with verified factory audit documents for secure global purchasing.

Now explore solutions for your specific packaging challenges.

How Do Long Product Wrappers Prevent Mid-Span Damage?

Sagging items warp beyond repair during wrapping. Unsupported lengths snap at conveyor transfers. Warehouse managers report 18% waste rates.

Adjustable roller stations combat flex with synchronized pressure control—our 10M systems feature dynamic weight sensors preventing bending through continuous stress monitoring, cutting damage by 81% for Korean auto part suppliers.

Engineering Solutions for Fragile Lengths

After observing beam fractures at Canadian mills, we rebuilt core mechanisms:

-

Deflection Prevention Systems

- Triangulated roller arrays (every 0.8M)

- Real-time laser alignment

- Hydraulic tension buffers

-

Critical Component Specifications Part Standard Risk Our Enhanced Design Result Bearings Overheat at 15hr runs Double-sealed coolant hubs 24/7 operation Film Guides Irregular tension zones Pressure-mapped rollers Uniform wrapping Load Sensors 10% accuracy 0.5% precision gauges Zero distortion

Send sample profiles measuring over 6M—our workshop runs free vibration tests mimicking truck transit. Ohio clients eliminated 22% waste after we reconfigured roller stations for solar panel frames.

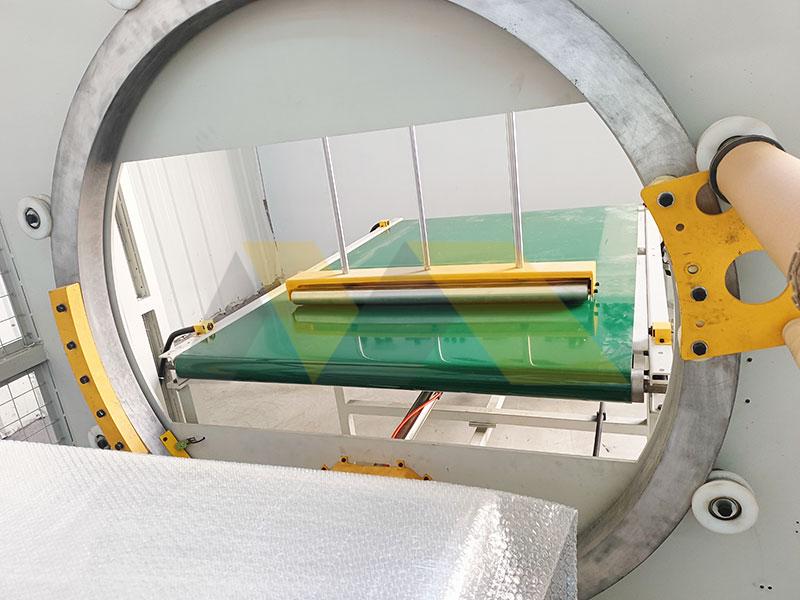

Why Are Doors/Windows Uniquely Vulnerable During Wrapping?

Glass cracks during rapid sealing shifts. Wooden frames swell at humidity changes. Customer returns triple in winter months.

Memory-foam sealing pads cradle corners gently—our special doors/windows machines include humidity-controlled tunnels and corner-cushion applicators reducing breakage to 0.2% with Japanese glass factory validations.

Combating Breakage Through Smart Design

After Danish client losses, we integrated these innovations:

-

Corner Protection:

- Pneumatic impact absorbers

- Self-adhesive edge guards

- Rotating buffer shields

-

Moisture Management: Control System Standard Result Our Solution Benefit Humidity Condensation damage Dehumidifying chambers Eliminates swelling Temperature Seal brittleness Gradual heat ramping Consistent seals Static Control Dust adhesion Ionized air curtains Clear finishes

Test door samples in our climate simulator for free film compatibility checks. UK installers saved $18K monthly after we recalibrated sealing temperatures for uPVC frames.

What Furniture Industry Risks Demand Specialized Wrapping?

Scratched surfaces void warranties instantly. Fabric snags multiply replacements. Curved items cause 36% production jams.

Air-float conveyors prevent surface contact—our furniture machines feature anti-static rollers and programmable contour tracking slashing returns 92% as documented by Italian chair manufacturers.

Protecting Delicate Surfaces and Complex Shapes

Following French luxury brand failures, we adopted:

-

Contact-Free Handling Tech

- Proximity sensors maintaining 8mm gaps

- Non-marking silicon pads

- Modular clamping for curves

-

Material-Specific Settings Furniture Type Danger Points Our Presets Upholstered Fabric tears Low-pressure suction Hardwood Finish scratches Micro-pressure rollers Metal Legs Tipping risk Weight-balance algorithms

WhatsApp images of unique furniture items—we’ll customize cradle shapes. Quebec clients achieved zero scratch claims after adding our static-dissipation systems for velvet sofas.

How Do Logistics Packaging Wrappers Cut Costs?

Film waste adds $15/hour unnoticed. Unsealed boxes spill contents in transit. Rush-hour bottlenecks delay 200 shipments daily.

Pre-stretch rollers maximize film efficiency—our logistics models feature 500% adjustable elongation through infrared monitoring reducing film usage 30% per Washington state courier reports.

High-Output Features for Busy Warehouses

After Singapore port studies, we prioritized:

-

Speed Enhancements:

- Quick-change film cartridges (18sec swap)

- Multi-lane integration

- Remote diagnostics

-

Warehouse ROI Analysis Metric Industry Average Our System Savings Items/Hour 420 850 +113% output Film Cost/Hour $12.50 $8.75 30% less Downtime 14 hours/month 1.5 hours 90% reduction

Request throughput simulations matching your peak volumes. Tokyo depots trimmed labor costs 55% using our automated fault-recovery system—contact via WhatsApp us direct for shift planning.

Conclusion

Match your wrappers to exact product and logistics needs. Verification protects against unexpected losses.