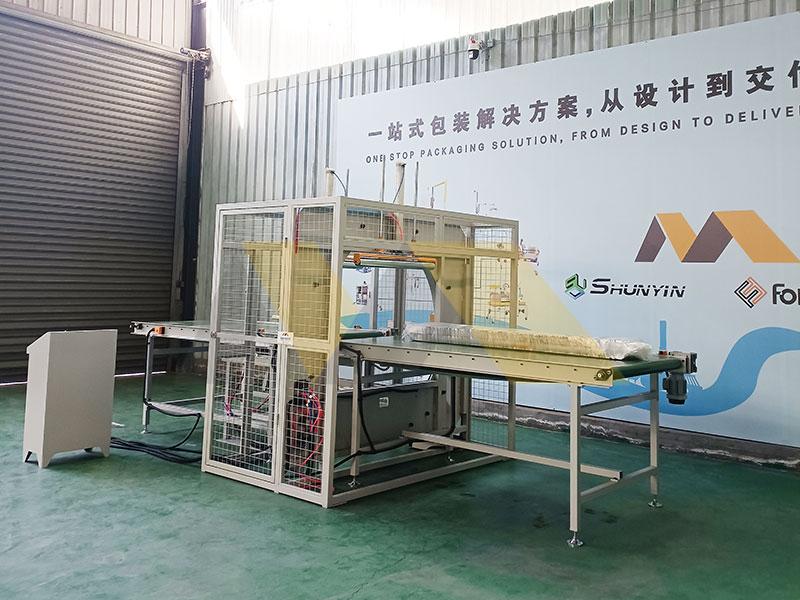

Starting a packing machine wholesale business? Sourcing reliable horizontal wrappers can be frustrating. Unreasonable prices, inconsistent quality, and hidden costs often plague buyers. I’ve faced those setbacks when building our factory from scratch. Quality and fair pricing make all the difference.

Horizontal wrapping equipment wholesale involves sourcing machines in bulk directly from manufacturers like us at Myway. For resellers, wholesale price lists range from $1,500 to $15,000 per unit based on automation level. Bulk discounts of 5-20% apply for orders exceeding 10 machines.

Smart buyers compare technical specs between suppliers firsthand. I’ve seen resellers lose profits from choosing unreliable partners. Let’s explore how to secure premium machines without overspending.

What Factors Affect Horizontal Wrapping Machine Cost?

Sticker shock hits when suppliers hide fees. Shipping charges or unnecessary "premium" components inflate prices overnight. I recall one client overpaying by 40% before partnering with us. Clear costing prevents these surprises.

Core factors like automation level and material durability primarily determine horizontal wrapping machine cost. Semi-automatic models start around $1,500, while AI-driven systems reach $15,000. Production volume capacity adds another 15-30% to the base price.

Key Cost Variables to Consider

Focus on these specifications during supplier negotiations:

| Feature | Budget Impact | Ideal Range |

|---|---|---|

| Speed Setting | ±$2200 | 10-40 cycles/minute |

| Materials Used | ±$3700 | 304 stainless steel |

| Brand Components | ±$1850 | Mitsubishi/Siemens |

| Customization | +15-25% | Adapts to product size |

| Shipping | +400-1100$ | Depends on container size |

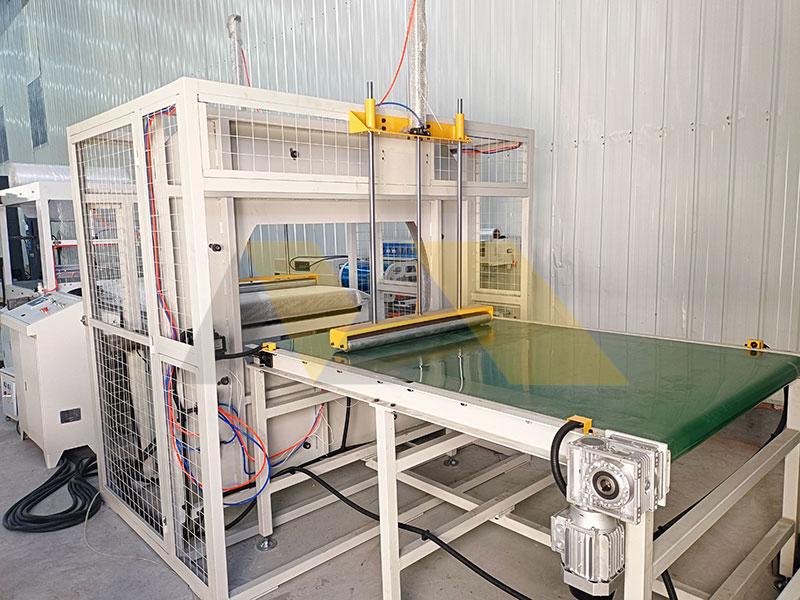

Production line tests reveal true durability. Early in my career, we cut corners on stainless steel thickness. Result? Machines failed within months. Now we use 2mm 304-grade steel for all vital parts – zero corrosion complaints since 2018.

Bulk discounts scale with order size:

- 5-10 units: 5% discount

- 11-20 units: 12% discount

- 20+ units: 20% discount

Request dimensional data before finalizing shipments. We provide precise container optimization charts showing how many units fit per 20ft/40ft container. Want personalized calculations? WhatsApp us direct.

How Accurate Are Horizontal Wrapping Machine Price Lists?

Published price lists often exclude taxes and shipping. Last quarter, three resellers received invoices 25% higher than advertised. That strains business relationships unnecessarily. We maintain real-time pricing transparency.

Trustworthy horizontal wrapping machine price lists itemize core components, taxes, and shipping separately. Legitimate suppliers update these quarterly with current steel/circuit board costs. Request breakdowns confirming voltage compatibility with destination countries.

Verifying Pricing Accuracy

Follow this verification checklist:

Cross-Check Material Costs

Market copper and steel prices fluctuate weekly. Reputable manufacturers will explain cost adjustments openly. We include quarterly material expenditure audit reports.

Confirm Payment Security

Insist these payment terms:

- Letter of Credit protection

- 30% deposit requirement

- Warranty-holdback clauses

Test After-Sales Support Costs

Hidden expenses emerge during breakdowns. Ask:

- Are replacement parts stocked locally?

- Is remote troubleshooting free?

- What’s hourly technician rate?

One Canadian partner saved $17,000 annually when we pre-shipped commonly replaced components. Avoid operational shutdowns by insisting on these details. Send your location on WhatsApp for region-specific support options.

Can Cheap Horizontal Wrapping Machines Ensure Quality?

Budget machines tempt resellers, but repairs bankrupt businesses. A Toronto client bought "cheap" competitors’ units last year. Five malfunctioned during winter – condensation fried circuit boards. Replacement costs exceeded initial savings.

Truly economical cheap horizontal wrapping machines maintain industrial standards through simplified designs rather than inferior materials. Verified certifications like CE/UL prove adherence to safety protocols. Avoid units with non-steel frames or generic brand motors.

Identifying Cost-Effective Features

These features prevent future expenses:

Low-Maintenance Engineering

Seek:

- Brushless DC motors

- Tool-free belt adjustments

- Dust-resistant control panels

- Self-lubricating rails

Certification Validation Tactics

Verify documentation authenticity through:

- Issuing agency website cross-checks

- Batch number validation

- Physical sample testing reports

Smart Customization Savings

Focus modifications on your products:

- Adjustable height tunnels

- Interchangeable film holders

- Modular conveyor extensions

Our engineers optimize these factors without price inflation. Share your product dimensions on WhatsApp – we’ll configure machines eliminating unnecessary features.

How Should You Obtain a Horizontal Wrapping Machine Quotation?

Generic quotes waste negotiation time. Last month, a Japanese distributor received three proposals with incompatible voltage specs. Proper quotations mirror unique business needs precisely.

Professional horizontal wrapping machine quotations specify technical adaptations for target markets like North America/Japan. They include logistics fees by sea/air and payment term options. Valid quotes list component brands showing quality commitment.

Quotation Comparison Strategies

Evaluate proposals using these criteria:

| Basic Quote | Superior Quote | |

|---|---|---|

| Delivery Timeline | Vague estimate | Production stage dates |

| Compliance Docs | Generic certificates | Market-specific declarations |

| Warranty Terms | Standard boilerplate | Local provider contacts |

| Spares Package | Optional add-on | First-year essential parts included |

Submit packaging samples to factories – we test material tension settings against actual products. This prevents misconfigurations causing film tears during operation.

Require video walkthroughs verifying factory ownership. We record facilities tours showing production lines matching order volumes. Need a verified quotation for Canada? WhatsApp us direct with container requirements.

Conclusion

Smart horizontal equipment wholesale requires transparent pricing, authentic certifications and supplier verification. Focus negotiations on genuine cost-savers without compromising performance. Select partners proving factory reliability consistently.