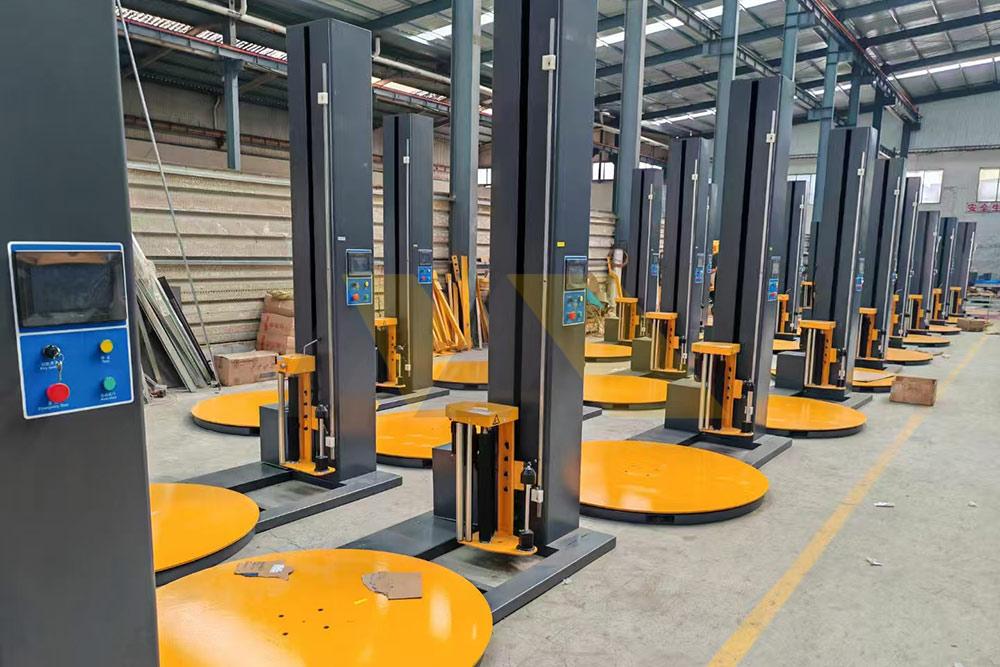

Struggling to find a reliable pallet wrapper maker? We know factory buyers face risks like poor quality and inflated prices. Myway solves this problem by delivering robust machines straight from our 5 production lines.

Selecting the best pallet wrapping machine manufacturer means verifying their factory certifications, production capacity, and customization options first. Prioritize ISO-certified suppliers with raw material quality control—this prevents breakdowns and saves long-term costs. Check their export history to your target markets too.

We understand your frustration when suppliers disappear after taking deposits. That’s why at Myway, we photograph every production stage for clients. We’ve shipped to Singapore ports in 10 days flat! Let’s explore how to secure machines that actually meet your warehouse needs.

Need a Pallet Wrapping Machine Quotation?

Getting inaccurate quotes wastes weeks. I once had a client lose $8k due to hidden transport costs in an unclear quotation. Request line-item breakdowns immediately.

Transparent pallet wrapping machine quotations must detail machine specs, material costs, labor fees, and ALL logistics charges upfront. Always compare the warranty period and spare part prices across 3+ suppliers before deciding.

7 Quotation Elements You Must Verify

Don’t accept vague proposals. Ask us for a template checklist we use internally. For now, inspect these:

- Motor power ratings – Higher wattage reduces jams during heavy-load wrapping

- Film consumption rates – Impacts long-term operational costs

- Pre-shipment testing terms – Must include video proof

Shipping & Payment Risks

| Risk Type | Prevention Strategy | Myway’s Approach |

|---|---|---|

| Port delays | FOB Incoterms clarity | Live container tracking |

| Currency gaps | USD/EUR fixed rates | 30% deposit, 70% before shipment |

| Customs holds | HS code validation | Export docs prepared in-house |

We caught a client’s incorrect voltage spec last month before shipping – that saved 3 weeks of returns. Message us on WhatsApp direct for real-time quote adjustments as you compare options.

Want a Cheap Pallet Wrapping Machine?

“Cheap” machines often lack safety guards. We repaired one last year where finger sensors were missing – $4k cheaper became $12k in lawsuit risks.

True cheap pallet wrapping machines maintain CE-certified components while eliminating non-essential features like touchscreens. Focus on semi-automatic models with galvanized steel frames for 10+ year durability at 40% lower cost than premium brands.

Where Costs Hide

I’ll show you exactly how we cut prices without quality loss:

Material Savings Guide

| Standard Part | Cost-Cut Alternative | Savings Impact |

|---|---|---|

| German PLC | Japanese controller | 22% reduction |

| Stainless conveyor | Powder-coated carbon steel | 33% cheaper, same lifespan |

| Hydraulic arms | Electric servo motors | Saves $500/year in maintenance |

We stock modular components to build custom low-cost machines in 8 days. Remember – your "extra savings" shouldn’t require 6-hour phone calls for adjustments! Our engineers configure specs while you watch via WeChat video. Tell us your budget via WhatsApp – we’ll send 3 solutions within 4 hours.

How to Get the Best Price on Pallet Wrapping Machine?

Buyers often compromise specs for discounts. Big mistake! Our top-performing client benchmarks prices by output efficiency, not upfront cost ($/wrapped pallet).

Securing the best pallet wrapping machine price requires quarterly bulk purchases. Combine orders with non-competing buyers for container-load discounts. Time orders in February/March when Chinese factories need post-holiday production.

Bulk Purchasing Power

Strategic Timing

Q1 (Jan-Mar)

- Post-Chinese New Year slump = 12% average discounts

- Factories clear inventory for new models

Q3 (Jul-Sep)

- Pre-Q4 export rush = faster production slots

Volume Discount Tiers

| Units Ordered | Price Reduction | Lead Time |

|---|---|---|

| 1-5 | Standard pricing | 15 days |

| 6-10 | 8% off | 20 days |

| 11-20 | 15% off | 25 days |

We reserve steel allocations monthly so our price locks stay firm for 45 days. Last quarter, a Canadian reseller saved $11k combining orders with a Mexican partner. Share your quarterly projections on WhatsApp direct – we’ll create group-buy opportunities.

Where to Find Low-Cost Pallet Wrapping Machines?

Vietnam factories undercut prices but often use recycled motors. We tested 3 “bargain” units from Hanoi last year – all overheated at 100+ pallets/day.

Authentic low-cost pallet wrapping machines come from ISO 9001 Chinese manufacturers near industrial zones like Guangdong. Avoid trading companies – direct factory contracts like ours cut 18% middleman fees while ensuring material traceability.

Supply Chain Transparency

Verifying Real Factories

Physical Checks:

- Video tour of workshop (look for automated welding robots)

- Raw material purchase invoices

- Worker count verification (under 100 hints at outsourcing)

Hidden Cost Comparison

| Sourcing Type | Price | Material Risk | QC Control |

|---|---|---|---|

| Trading Agent | $$ | High – unknown substitutions | Limited |

| Direct Factory | $ | Low – BOM documentation | Full process access |

We email mill certificates for every steel batch. Just last week, a Toronto buyer avoided aluminum alloy frames after reviewing our material specs. Send your risk checklist via WhatsApp – we’ll sign inspection protocol memos before production starts.

Conclusion

Choose manufacturers with transparent quotes, volume discounts, and material traceability to balance cost and reliability. Start your no-pressure consultation today.