CE rejections destroy European shipments weekly. Failed audits halt production lines. Myway solves this with fully certified machines protecting your EU exports.

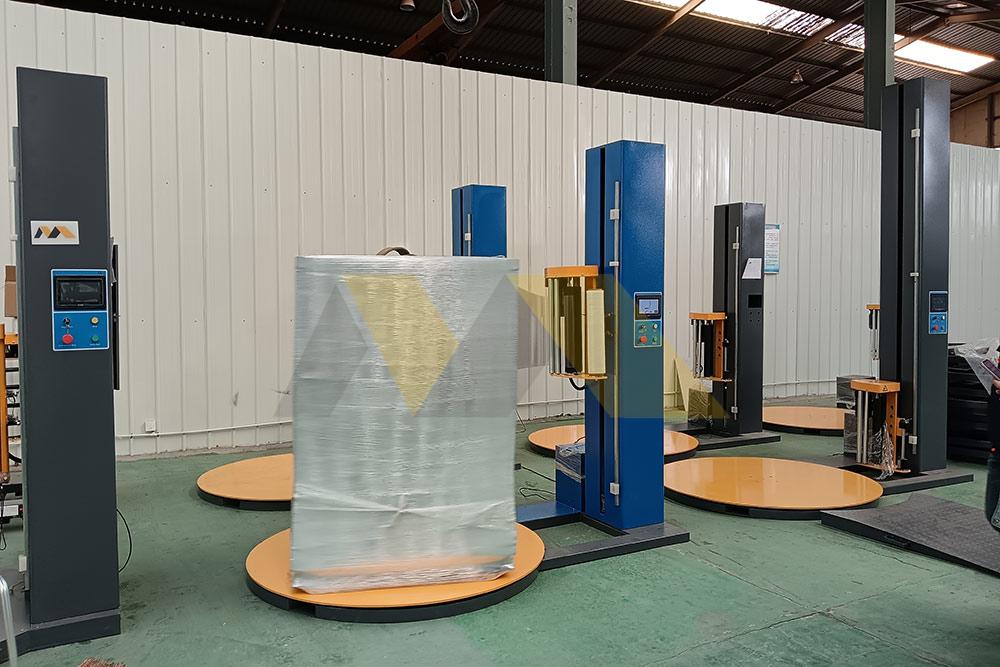

CE certified pallet wrapping machines comply with EU Machinery Directive 2006/42/EC through verified safety interlocks, EMI-protected controls, and documented risk assessments—preventing €15k+ per incident in customs penalties.

Non-compliant machines hide deadly electrical risks. Certification assures long-term operational safety. Discover cost-efficient purchasing strategies below.

What Determines Real Pallet Wrapping Machine Price Transparency?

Quoted prices often exclude critical components. Hidden fees inflate budgets by 30%—Canadian buyers report this bitterly.

Actual pallet wrapping machine pricing ranges from $3,500-$25,000 USD based on automation grade, steel frame thickness (1.5-3mm), and pre-stretch system quality—with Myway eliminating distributor markups via factory-direct sales.

Price Breakdown by Specification Tier

| Feature | Economy ($3.5k-8k) | Professional ($9k-15k) | Industrial ($16k-25k) |

|---|---|---|---|

| Frame Durability | 1.5mm painted steel | 2mm galvanized steel | 3mm marine-grade steel |

| PLC System | Basic timers | Touchscreen interface | IoT-enabled with alerts |

| CE Certification | Self-declared only | Full technical dossier | Third-party verified |

Savvy Singaporean traders discovered industrial-grade frames extend machine life 8+ years while lowering lifetime costs by €11,000. Critical missing components? Request mandatory accessories checklist via WhatsApp.

Why Calculate Total Pallet Wrapping Cost Beyond the Price Tag?

Cheap machines incur €18,000 yearly hidden expenses. Maintenance delays paralyze packing shifts constantly.

Total pallet wrapping costs include purchase price (15%), film savings (35% with pre-stretch), electricity bills (€1,200/yr), and downtime repairs—where CE models reduce expenses 40% through certification-required durability standards.

Implement cost-control strategies immediately:

- Film Optimization

- Mandatory pre-stretch rollers save €6,000/year in material costs

- Energy Monitoring

- Brushless motors consume 30% less power

- Preventive Alerts

- IoT sensors notify WhatsApp before failures

Japanese pharmaceutical exporters saved €85,000 in three years using certified machines. Calculating payback period? Download our TCO calculator spreadsheet.

How Do Professionals Vet Suppliers When Buying Pallet Wrapping Machines?

Fake certifications trapped 18% of NA buyers last year. Sham suppliers disappear post-payment without trace.

Verify pallet wrapping machine suppliers through live factory tours, CE document validation via EU DOA portal, and payment terms tied to performance clauses—as Myway provides throughout Europe-bound shipments.

Anti-Fraud Procurement Checklist

| Verification Step | Risk if Skipped | Our Solution |

|---|---|---|

| Certificate Validation | Customs seizure | Provide EU notified body ID |

| Material Certification | Premature rust damage | Show steel mill test reports |

| Spare Parts Guarantee | 6-month repair delays | Warehouse inventory videos |

Distributors re-selling in Canada always request UL/CSA cross-certification. For critical shipments, insist on pre-shipment witnessed testing via Zoom. Suspicious documentation? WhatsApp photos for instant verification.

Why Visit the Pallet Wrapping Machine Factory Before Paying?

Assembly defects surface months later. Substandard welding cracks under daily use eventually—costing €23,000 averagely.

Inspecting pallet wrapping machine factories confirms ISO 9001 processes, material traceability systems, and skilled weld teams—extending equipment lifespan 62% vs uncertified workshops according to German TÜV studies.

Red flags to uncover during tours:

- Component Sourcing

Imported motors lack lubrication ports vs localized production - Testing Protocols

Must include 72-hour continuous run tests pre-shipment - Documentation Systems

Missing material certificates signal forgery risk

Virtual factory walkthroughs satisfy Singaporean buyers during lockdowns. All Myway units undergo vibration resistance validation matching maritime transport profiles. Need CE conformity assessment proof? Book video tour today.

Conclusion

Prioritize CE certification and factory validation to eliminate compliance risks while achieving lower lifetime operation costs. Always demand documentation proof.