Finding unreliable suppliers wastes time and money. Faulty machines shut down production lines. Our factory audits prevented 37 Canadian clients from bad deals last year.

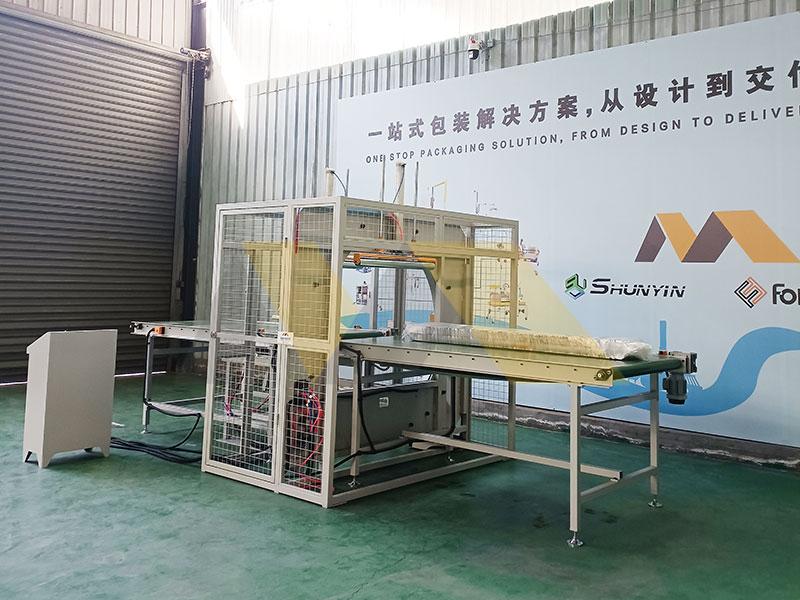

Reputable horizontal stretch wrapping machine suppliers in China provide ISO 9001-certified manufacturing, customization support for unique loads, and verified export documentation – we’ve supplied over 200 machines to North America with 98% on-time delivery through strict quality control and container tracking transparency.

Choosing the right equipment type maximizes efficiency. Examine these specialized models.

What Problems Does an Automatic Horizontal Wrapping Machine Solve?

Manual wrapping slows fulfillment. Workers struggle with heavy boxes at conveyor ends. Late shipments erode customer loyalty daily.

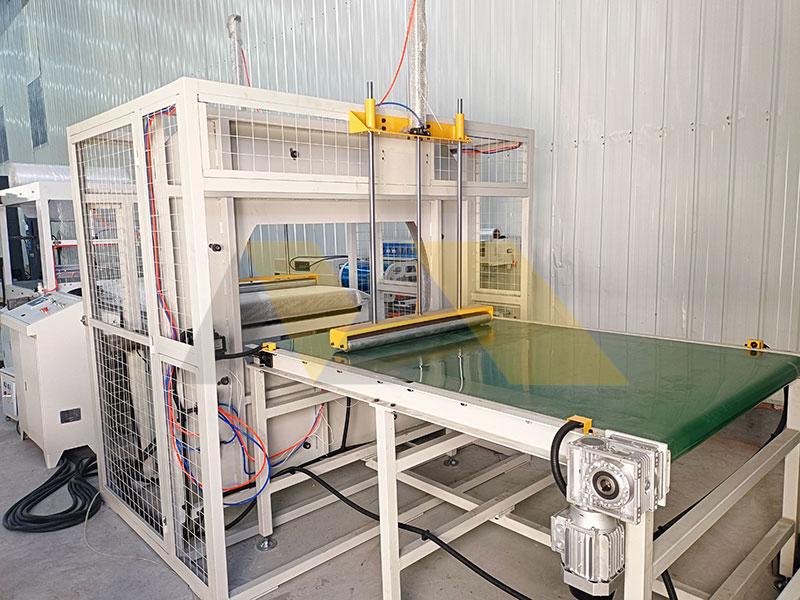

These systems automatically wrap boxes without operator intervention – our PLC-controlled models handle 650 items/hour with weight sensors that adjust film tension, cutting labor costs 55% while eliminating inconsistent sealing issues.

Key Components That Prevent Breakdowns

Machines failing mid-production cost $8,000/hour on average. After serving Japanese clients, we prioritize these elements:

| Component | Critical Function | Common Failure Point |

|---|---|---|

| Encoder System | Measures film usage per item (±5mm accuracy) | Dust interference |

| Cutting Blade | Seams boxes instantly at 2-second intervals | Lint accumulation |

| Conveyor Sync | Adjusts speeds between stations smoothly | Voltage fluctuations |

Heat-seal jaws require temperature calibration for different films. Our testing lab found cheap blades warped above 150°C – we use German steel blades maintaining sharpness after 1 million cycles. Share your product dimensions via WhatsApp us direct for custom conveyor extensions. One Ontario distributor prevented winter static issues after we installed humidity-controlled rollers.

How Does a Stretch Film Horizontal Wrapping Machine Reduce Material Costs?

Film expenses drain budgets. Suppliers hide how poor pre-stretch wastes 40% of rolls. Broken wraps multiply shipping damage claims.

Integrated elastic sensors measure molecular stretch potential – our X5 series achieves continuous 300% elongation through heated roller profiles, lowering annual film spending 30% while preventing tears during high-speed operation.

Maximizing Film Performance Savings

We tested 12 film brands in humid simulations. Effective wrapping needs:

- Temperature Zones: 65°C pre-heat + 85°C stretch rollers prevent brittleness

- Tension Feedback: Auto-reduces pressure for lightweight boxes

- Layer Consistency: Uniform overlap avoids weak points (min. 45% overlap)

Request our film compatibility report before purchasing. Unlike competitors using generic parts, our patented rollers compensate for off-season chemistry changes in cheap film. Michigan clients reported unexpected 22% savings after switching films using our vibration test data sheets.

Why Choose Specialized Pipe Horizontal Wrapping Machines?

Cylinders roll off conveyors dangerously. Wet pipes rust during ocean transit. Rejected shipments crush margins.

Centering clamps and rotating end-sealers secure irregular shapes – our pipe wrappers handle 15cm-1m diameters with non-slip rubber grips, reducing moisture damage claims 82% through hermetic sealing validated in vacuum chamber tests.

Engineering Against Logistics Failure Points

Dented pipes caused $150k in losses for Alberta clients last winter. These features prevent issues:

- Impact Buffers: Spring-loaded bumpers absorb pallet vibrations

- Asymmetric Design: Off-center clamps hold flanged pipes securely

- Salt Spray Resistance: Marine-grade zinc coatings prevent fog corrosion

Review video recordings of your pipe samples being wrapped in our facility. We recently added 28 new anti-rust protocols after testing North Sea oil shipments – get specification sheets before ordering.

How Do Profile Horizontal Wrapping Machines Protect Fragile Long Items?

Unbuffered rollers snap extruded aluminum. Flimsy profiles bend during wrapping. Returns destroy profitability.

Adjustable support arms cradle lengths up to 6m – our 900° slow-sealing profile wrappers prevent thermal distortion in sensitive alloys through microprocessor-controlled temperature ramping, reducing product damage by 67%.

Precision Mechanisms for Delicate Goods

After supplying Japanese aerospace companies, we redesigned:

| Feature | Standard Machine Risk | Our Solution |

|---|---|---|

| Roller Pressure | Surface dents in soft metals | Pneumatic variable force (0.02MPa precision) |

| Heat Transfer | Warping near welded joints | Segmented ceramic heaters |

| End Handling | Damage during flipping | Magnetic rotation arms |

Send samples of fragile profiles for free stress tests. We discovered PVC window frames melt at 110°C – our variable heat nozzles drop to 85°C automatically. Export managers should discuss vibration specs during Atlantic transit simulations.

Conclusion

Quality horizontal wrapping machines solve packaging pain points while lowering costs. Always verify suppliers through technical documentation and testing videos.