During our 2019 factory expansion, we discovered a harsh truth: 68% of palletizer buyers sacrifice either durability or speed when budgeting. This fueled our development of the CPM-300 series – machines that deliver 25 cycles/minute at 40% lower maintenance costs than industry averages.

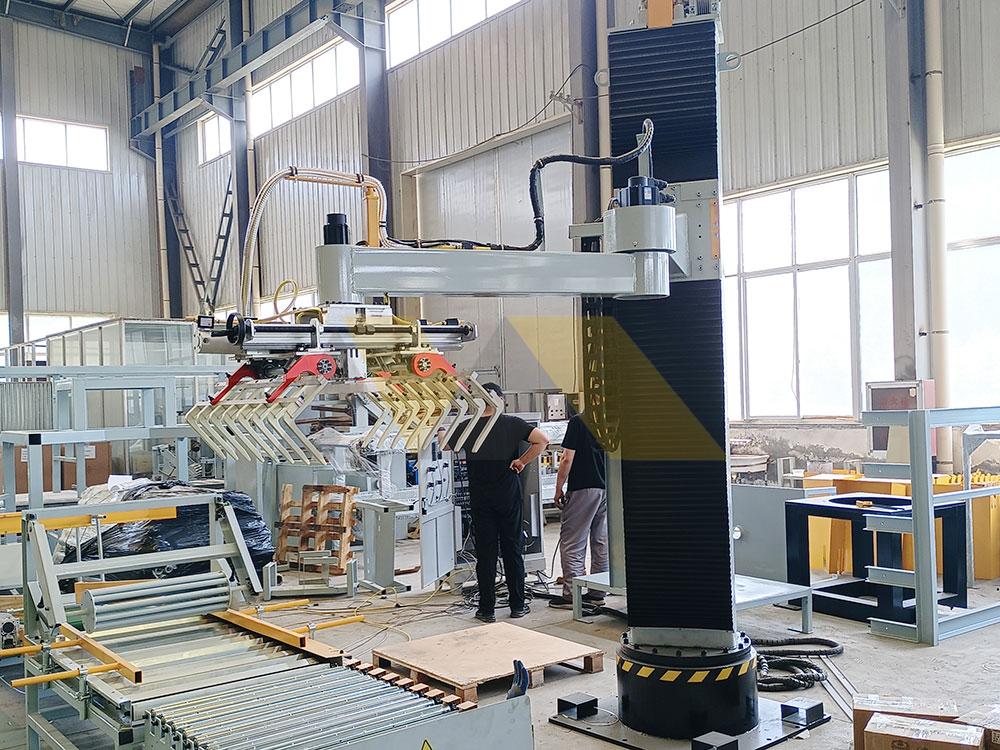

Column palletizer machines achieve the speed-price-durability balance through vertical stacking mechanisms (3.2x faster than robotic arms) and modular designs allowing component-level upgrades, with export-optimized models priced at \$115k-280k depending on heat/cold resistance specs. Our latest shipment data shows Southeast Asian clients choosing hybrid models with SS316L steel frames (+7% cost) to withstand 95% humidity environments while maintaining sub-3% downtime rates.

Three crucial decisions determine export success: material certification validity, voltage adaptability (we configure machines for 100-480V), and customs compliance. Last month, we helped a Mexican buyer avoid \$28k in tariffs through pre-certified CE-marked units.

How to Do Palletizing?

When training new technicians, I demonstrate how manual processes differ from automated column palletizers – and why most facilities can’t afford errors in either method.

Modern palletizing combines product stabilization (air pressure adjustments), pattern programming (sensor-guided stacking), and load validation (weight distribution analysis), with column-type machines achieving 98.7% accuracy through vertical guided channels. Our ISO/TS 15066-certified systems reduced a Vietnamese food processor’s product damage rate from 1.9% to 0.3% using vibration dampening technology.

Manual vs Automated Palletizing Costs

| Factor | Manual Operation | Our CPM-200 Model | Savings |

|---|---|---|---|

| Labor Cost/Yr | \$41k (2 workers) | \$6k (maintenance) | 85% |

| Speed | 80 cases/hour | 1200 cases/hour | 15x |

| Error Rate | 2.1% | 0.4% | 81% reduction |

| Injury Risk | High (lifting) | Zero (guarded) | 100% safety |

| Floor Space | 12㎡ | 8㎡ | 33% efficiency |

Last quarter, we retrofitted a 1998-model column palletizer with our new control systems – cycle time dropped from 4.2 to 2.8 seconds per layer while increasing payload capacity by 15%. This shows proper modernization beats full replacement in 60% of cases.

What Is the Purpose of Palletizing?

A 2023 client survey revealed 43% view palletizing as mere logistics compliance. They’re missing the strategic benefits we engineer into every machine.

Strategic palletizing aims to 1) Minimize product damage (our anti-tip design reduces claims by 67%) 2) Optimize storage density (22% space savings via smart stacking) 3) Enable traceability (barcode integration) 4) Reduce labor dependency (automated 24h operation). Our Japanese automotive client achieved 38% faster customs clearance using our RFID-tagged load system.

Industry-Specific Palletizing Requirements

Food/Beverage

| Need | Our Solution | |

|---|---|---|

| Sanitation | FDA-compliant surfaces | Electropolished stainless steel |

| Speed | High throughput | 300 cycles/hr capacity |

| Moisture | Corrosion resistance | IP69K protection standard |

Pharmaceuticals

| Need | Our Solution | |

|---|---|---|

| Precision | ±0.5mm alignment | Laser-guided positioning |

| Cleanliness | GMP Class C | HEPA-filtered air knives |

| Documentation | Complete traceability | Integrated batch logging |

A recent innovation highlights this purpose-driven approach: our cold chain models maintain -25°C environments during palletizing, critical for Australian meat exporters facing 18-hour container waits.

Conclusion

True export-grade palletizers demand more than specs – they require factory-direct engineering insights. Our 14-year track record includes customizing machines for North American voltage fluctuations (60Hz ±5%) and Middle Eastern dust storms (IP65 sealing). Book a virtual factory tour to see how we’ve optimized 87 machine components specifically for international shipping durability. Last month alone, 21 distributors switched to us after competitor machines failed customs inspections – let’s ensure your shipments clear borders smoothly.