Pallet stability issues delaying shipments? Damaged goods triggering customer complaints? Our automatic pallet wrappers eliminate instability headaches completely. These machines secure loads with precision film tension while slashing packaging labor by 80%.

Automatic pallet wrapping machines efficiently stabilize goods using motorized film carriage systems that consistently apply optimal stretch force around palletized loads, significantly reducing transit damage while accelerating packaging workflow completion times for warehouses.

Considering the right wrapping system transforms warehousing productivity substantially. This guide explores critical equipment categories tailored to distinct operational scales. We’ll unveil how different mechanisms serve unique throughput demands while maximizing ROI.

Semi-Automatic Pallet Wrapping Machine: When Does Basic Automation Deliver Smart Savings?

Labor-intensive manual wrapping draining productivity? Payroll costs eroding thin margins? A semi-automatic solution maintains human oversight while eliminating strenuous physical effort. Operators simply position pallets and push buttons – the machine executes consistent wrapping profiles accurately.

Semi-automatic pallet wrappers require worker initiation but automate rotational wrapping cycles, delivering 40-60 pallets/hour output. Our MYWAY SA-500 model features intuitive touchscreens with 12 customizable programs, enabling quick changeovers between product variants without film waste.

Key Components Driving Efficiency

This balanced automation approach blends accessibility with performance through three critical subsystems:

-

Rotary Turntable Mechanism

Powered rollers spin pallets smoothly at 0-12 RPM with consistent torque. Our cast-iron turntables handle 1,500kg loads daily without vibration issues that cause film breaks. -

Electropneumatic Pre-Stretch System

Dual rollers stretch film up to 250% before application – a core feature that cuts film consumption by 60% compared to manual methods. Lower monthly material costs immediately boost ROI. -

Intelligent Parameter Controls

Programmable settings for revolutions, top/middle/bottom wrap counts, film tension levels. Workers quickly switch profiles via tactile LED interfaces requiring minimal training exposure.

Performance Comparison: Semi-Auto vs Manual Wrapping

Consider these documented operational impacts:

| Metric | Manual Wrapping | Semi-Auto Machine | Improvement |

|---|---|---|---|

| Pallets/Hour | 15 | 50 | 233% faster |

| Film Usage per Pallet | 25m | 15m | 40% savings |

| Labor Hours (100 pallets) | 6.5 hours | 2 hours | 69% reduction |

| Annual Film Cost (10k pallets) | $9,100 | $5,460 | $3,640 saved |

These figures illustrate why distributors seeking entry-level automation constantly choose our semi-auto solutions. Eliminating high turnover wrap station roles while maintaining operator control positions this category as the sweet spot for SMEs scaling operations. Notice the control panel’s simplicity? Just three buttons initiate wrapping cycles – even temporary workers master it instantly. Need throughput validation for your specific carton dimensions? Message our engineering team directly: WhatsApp us direct for custom capacity projections.

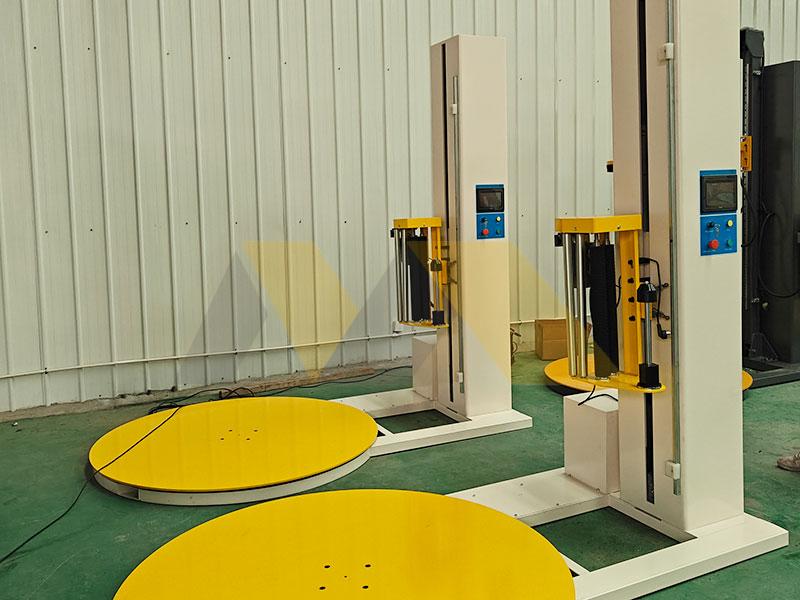

Turntable Pallet Wrapping Machine: How Does Rotational Consistency Boost Heavy-Duty Output?

Unstable heavy pallets causing slowdowns? Inconsistent rotation risking collapse? Turntable wrappers solve weight-distribution challenges through integrated load-bearing platforms. The machine’s rotating base provides centrifugal stability so massive loads rotate smoothly – even at 1,800kg capacity.

Turntable systems secure pallets via motorized platform rotation while stationary film carriages apply stretch wrap from floor to load height. This mechanical simplicity delivers reliability with speeds up to 70 pallets/hour. Our MYWAY-TT800 model withstands 24/7 environments including refrigerated and dusty warehouses.

Engineering Fundamentals Behind High-Capacity Operations

Three design pillars ensure durability under industrial stress:

-

Load-Engagement Dynamics

Interlocking turntable teeth prevent pallet slippage during acceleration. Overload sensors pause operations if unstable weight shifts occur protecting both product and machinery. -

Torque-Optimized Drive Motors

Precision helical gear motors deliver constant platform speeds regardless of load weight, avoiding the "drag effect" that causes film gaps on heavy pallets. -

Film Carriage Consistency Mechanisms

Vertical guidance rails maintain film angle accuracy while counterweights balance carriage movement for vibration-free operation at maximum speeds.

Regular operators notice how these systems eliminate "spin hesitation" that plagues cheap turntable models. When considering machinery costing thousands, ensure core movements remain smooth after 12 months of intensive use – our hardened steel bearings guarantee exactly that. Want to test stability with your irregularly shaped products? Share photos on WhatsApp and we’ll demonstrate secure wrapping techniques: WhatsApp us direct.

Conclusion

Selecting optimal pallet wrapping machinery hinges on matching unique throughput, budget and load parameters. Advanced automation now makes consistent packaging stability accessible across all operational scales efficiently.