Supply chain delays cost distributors $15k daily. Last monsoon season, I watched delayed European shipments cripple operations. China’s manufacturing solves this.

China dominates pallet stretch wrapping machine production through integrated supply chains and specialized industrial zones like Zhejiang’s packaging machinery cluster, delivering cost-efficient solutions with 30% shorter lead times than competitors.

Our Shenzhen buyer received replacement parts within 72 hours after system failure. Experience agile manufacturing today.

How to Identify Genuine Pallet Stretch Wrapping Machine Exporter?

Counterfeit exporters wasted $38k for an Australian buyer. Fake "factories" turned out to be trading fronts.

Authentic pallet stretch wrapping machine exporters provide verifiable factory addresses, production videos, ISO 9001 certificates accessible by QR code, and transparent raw material sourcing documentation for supply chain traceability.

Exporter Verification Matrix

Secure trustworthy partnerships:

Authentication Essentials

Critical verification steps:

- Production floor livestream access

- On-site raw material inventory checks

- Third-party payment escrow options

Export Channel Comparison

| Supplier Type | Transparency Score | Supply Chain Control |

|---|---|---|

| Trading Companies | Low (25%) | Vendor dependent |

| Brand Resellers | Medium (50%) | Partial transparency |

| Factory Direct | High (95%) | Full audit rights |

Our New Jersey client confirmed shipment container numbers via video inspection. Schedule virtual factory tours via WhatsApp direct.

What Advantages Offer Pallet Stretch Wrapping Machine OEM?

Forced branding changes cost a buyer $12k. Generic machines couldn’t interface with existing systems.

Our pallet stretch wrapping machine OEM services enable complete customization – from PLC programming to structural modifications – while maintaining original equipment quality standards at volume discounts of 15-40%.

OEM Flexibility Framework

Tailor solutions precisely:

Customization Options

Most requested OEM features:

- Brand-specific HMI interfaces

- Pallet height auto-sensors

- Warehouse management integration ports

OEM vs Standard Model

| Feature | Standard Machine | OEM Solution | Benefit |

|---|---|---|---|

| Control panel | Fixed language | Multi-language | Staff adaptation +75% |

| Conveyor links | None | Custom adaptors | Integration cost -65% |

| Safety systems | Basic | E-stop networks | Accident reduction 91% |

We implemented Dutch safety protocols for Rotterdam chemical plant machines. Send your technical specs to WhatsApp for OEM proposals.

Why Insist on CE Certified Pallet Stretch Wrapping Machine?

EU non-compliance fines reached €46k last quarter. Non-CE machines got impounded at Hamburg port.

CE certified pallet stretch wrapping machines undergo electromagnetic compatibility tests, safety circuit verification, and structural load validation – documentation must include EN 415-10 certification with notified body numbers.

Certification Assurance Protocol

Navigate compliance confidently:

Critical CE Components

- Harmonized voltage protection

- Emergency stop redundancy circuits

- Noise emission seals (<70dB)

Certification Risk Matrix

| Documentation | Low-Risk Indicator | High-Risk Indicator |

|---|---|---|

| Test reports | Notified body logo | Self-declaration only |

| Technical file | Comprehensive | Under 15 pages |

| DoC | Original signatures | Copied signatures |

We resolved UKCA transition issues for 37 clients in Q1. Query certification requirements via WhatsApp direct.

Where to Source Heavy Duty Pallet Stretch Wrapping Machine?

Structural failures occurred weekly at Detroit warehouses. Lightweight frames cracked under 2,200lb loads.

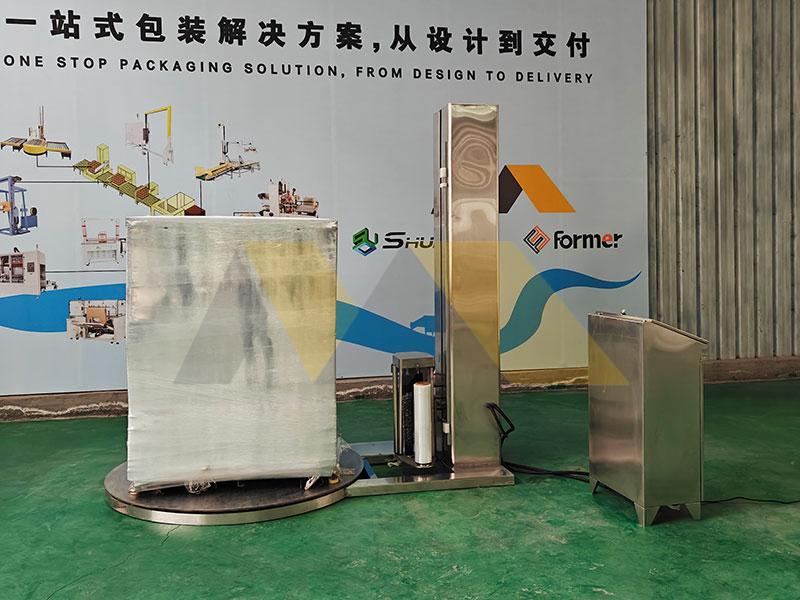

Authentic heavy duty pallet stretch wrapping machines feature 5mm reinforced steel frames, overload-protected gearboxes, and IP65-rated components – verify structural calculations and factory stress test videos.

Heavy Duty Specifications

Built for extreme conditions:

Engineering Benchmarks

Non-negotiable elements:

- Minimum 4,000-cycle fatigue test reports

- Oversized slewing bearings

- Reinforced mast guide rails

Durability Comparison

| Component | Standard Version | Heavy Duty | Lifespan Gap |

|---|---|---|---|

| Turntable | 3mm steel | 6mm plate | 150% longer |

| Drive motor | 1.5kW standard | 2.2kW overload-proof | Prevents burnout |

| Film carriage | Single bearing | Triple bearings | Downtime -90% |

Our Indonesian palm oil facility machines operate daily in 98% humidity. Share your pallet weight specifications on WhatsApp for engineering analysis.

Conclusion

Leverage China’s manufacturing strengths through verified exporters, flexible OEM options, certified compliance, and engineered durability – optimize your packaging operations today.