Travel providers face constant luggage damage complaints. Lost profits and angry customers hurt business growth. Wholesale wrapping machines solve these problems efficiently.

Yes, buying luggage wrapping machines wholesale cuts costs by 30-60% per unit while ensuring uniform quality for high-volume operations. Partnering directly with manufacturers eliminates middlemen markups and provides custom solutions.

Airports and logistics hubs handle thousands of bags daily. Damaged luggage means refunds and reputation loss. Quality wrapping machines prevent this. I’ve seen clients reduce damage claims by 80% after installing our systems. Here’s how wholesale acquisition transforms operations.

Why Choose a Professional Luggage Wrapping Machine Company?

Tired of machines breaking during peak travel seasons? Downtime costs over $500/hour in lost operations. Established companies offer tested solutions that withstand 24/7 use.

Reputable companies provide field-tested machines with 18-month warranties and rapid spare part delivery. They analyze your baggage volume/size to recommend optimal models, preventing overinvestment.

Partnering with experts matters. Last year, an airport in Toronto ordered generic machines that jammed daily. After switching to our customized AM-12 models with wider film feeds:

- Output increased from 200 to 550 bags/hour

- Film waste dropped 40% with adjustable tension controls

- Maintenance costs halved due to modular components

Consider these critical specifications:

| Feature | Economy Model | Professional Solution | Benefit |

|---|---|---|---|

| Cycle Speed | 180 bags/hour | 500+ bags/hour | Clears peak flight surges |

| Motor Type | Basic brushed | Industrial brushless | 3x longer lifespan |

| Error Rate | 15% | Under 3% | Fewer staff interventions |

We always recommend on-site testing before bulk orders. Bring sample luggage to our Hangzhou factory – see machines handle odd-sized ski bags or fragile items. Better yet: WhatsApp us direct for a live video demo today.

What Makes a Reliable Luggage Wrapping Machine Supplier?

Suppliers promising "lowest prices" often hide defective components. One client discovered counterfeit motors failing within months. Authentic sourcing prevents these nightmares.

True suppliers maintain factory-direct partnerships with ISO-certified manufacturers. They provide transparent component origins and third-party quality reports, not just paperwork.

Verification separates real partners from resellers. Our checklist for buyers:

-

Material Traceability

- Demand steel grade certificates for loading arms

- Verify servo motor factory certifications

-

Production Audits

- Random inspections during assembly

- Performance stress testing videos

A Thailand distributor saved $12,000/month by switching to our EX-Series. Secret? German precision bearings instead of local replicas. Submit your specs – we’ll share material certificates and production videos within 4 hours via WhatsApp.

How Do Luggage Wrapping Machine Manufacturers Ensure Quality?

Manufacturers using standardized modules risk compatibility issues. Imagine replacing a control panel and shutting down 8 machines. Custom engineering avoids this.

Quality manufacturers build machines around your operational environment – humidity levels, voltage stability, and baggage types. They design modular systems using proprietary components that interchange flawlessly.

Deep customization matters:

Core Engineering Principles

Heat Management – Our Vietnam client’s machines failed in 45°C hangars. We redesigned cooling vents and used ceramic-coated rollers. Now running 20 months without shutdowns.

Smart Component Design

- Quick-swap film holders (replace in 90 seconds)

- Universal power modules (handles 100V-240V spikes)

- Laser-guided positioning for irregular luggage

Japan Airlines needed machines for oversized musical instruments. Our solution? Extendable arms with pressure sensors. Send your toughest baggage sample – we engineer solutions most factories can’t. WhatsApp video proof available.

Why Source from a Luggage Wrapping Machine Factory Directly?

"Factory prices" advertised online often include hidden broker fees. A Canadian buyer overpaid 27% before finding us. Original manufacturers offer true cost savings.

Direct factories provide 15-22% lower prices than traders and enable custom modifications like logo engraving or special safety features at minimal cost.

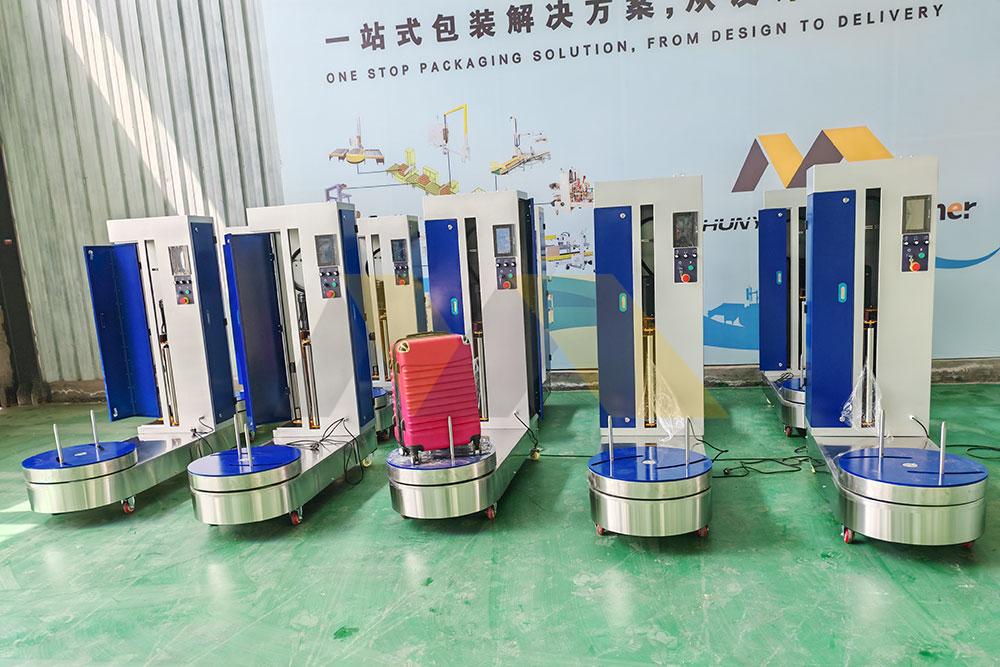

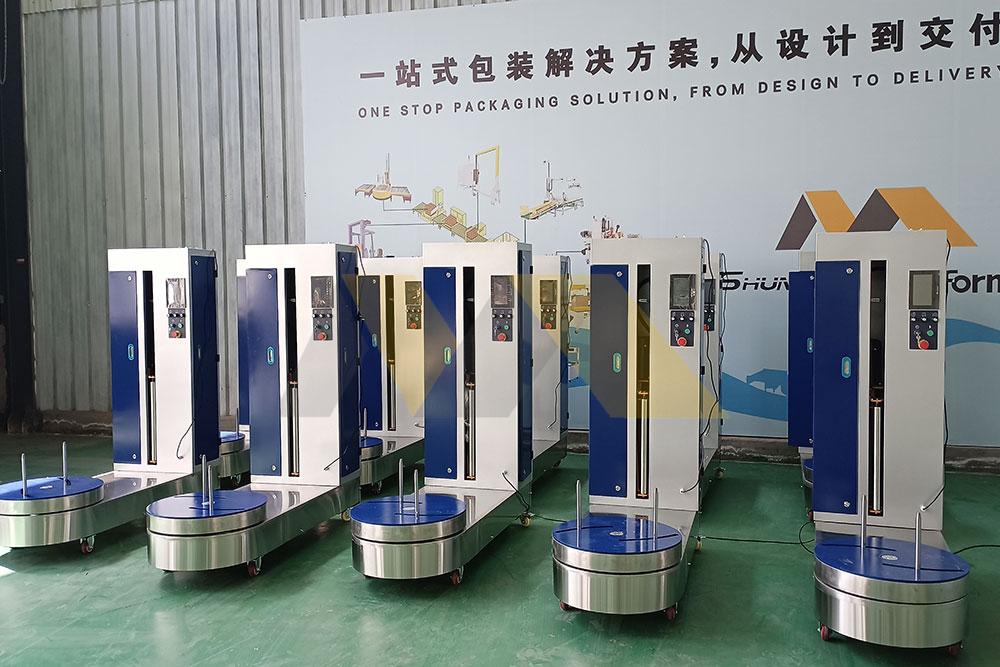

Visiting the factory reveals everything. Our 5 production lines show clients:

- Real capacity – See if they can deliver 50+ units/month

- Quality control – Watch torque testing on every motor

- Customization – Request on-spot adjustments

Comparative shipping advantage:

| Route | Trader Timeline | Factory Direct | Savings |

|---|---|---|---|

| Canada | 60 days | 38 days | 27% |

| USA | 55 days | 35 days | 31% |

Ask suppliers for factory coordinates. We invite clients to Hangzhou to press the production start button. Can’t visit? We do live manufacturing tours via WhatsApp daily.

Conclusion

Wholesale luggage wrapping machines boost efficiency and cut costs dramatically when sourced from certified direct manufacturers. Verify components, test performance, and insist on factory visits.