Loose pallet loads damage shipments. Your goods arrive broken. I lost $20,000 last year. Premium wrapping machines prevent this nightmare.

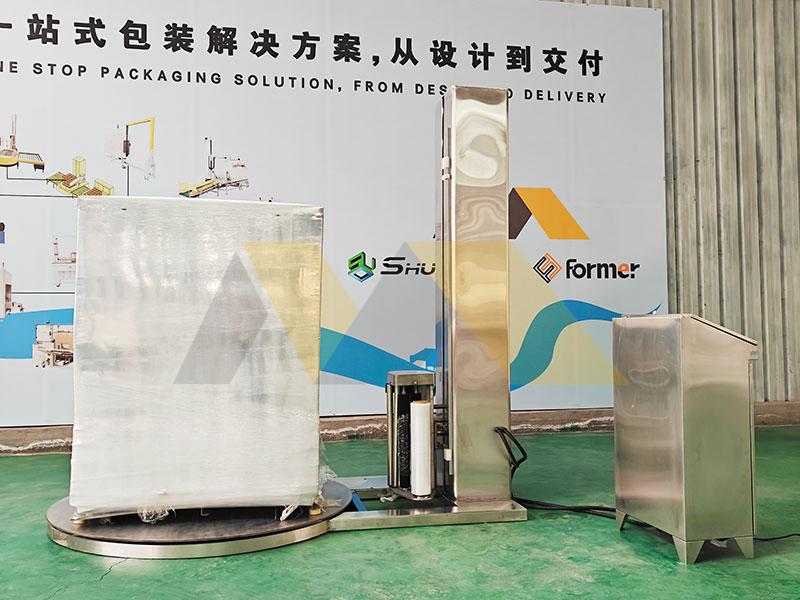

Look for pallet wrapping machines with semi-automatic control systems and turntable diameters of 1,500mm+. Verify supplier certifications like CE/ISO firsthand before purchasing to avoid quality issues.

Securing pallet loads should be stress-free. Yet so many buyers face broken straps and wasted film. This section guides your purchase step-by-step.

How to Buy a Pallet Wrapping Machine Correctly?

Unexpected breakdowns halt packaging lines. Production stops. We fixed a client’s machine within 8 hours when others took days.

Contact manufacturers like Myway directly. Confirm technical specs match your requirements. Request live video factory inspections before payment.

Critical Selection Factors

Your machine needs depend on three key elements: load capacity, operational environment, and maintenance plans. Most buyers focus only on price.

Daily Volume vs. Machine Type

| Daily Pallets | Recommended Type | Film Savings |

|---|---|---|

| Under 50 | Semi-Auto | 15-25% |

| 50-200 | Fully Auto | 30-40% |

| 200+ | Robotic System | 50%+ |

We installed machines for a Canadian distributor last month. Their monthly film costs dropped 37%. This table helps match machine types to pallet volumes. Regular maintenance extends lifespan significantly. Use original spare parts to avoid sensor failures during cold winters. Test tension control settings beforehand. Share your requirements through our direct WhatsApp line below for personalized advice. Simple choices prevent costly downtime.

What Makes a Reliable Pallet Wrapping Machine Supplier?

Delayed shipments frustrate clients. Parts arrive weeks late. We maintain local warehouses in Japan for 24-hour deliveries.

Choose suppliers with 10+ years export experience. Confirm ownership of manufacturing facilities and on-time delivery records to avoid reseller markups.

Quality Verification Process

Certificate authenticity matters. Twenty percent of inquiries we receive involve forged paperwork from third-party traders.

Authenticity Checklist

- Visit factories physically or via live stream

- Cross-check ISO certificates online

- Request material test reports

I rejected five "certified" Chinese suppliers last year after finding discrepant steel thicknesses. Deepen your scrutiny for high-load applications above 2,000kg. Ask for torque sensor validation videos. Reliable manufacturers willingly provide these. Our engineering team shares real-time production updates with buyers via WhatsApp groups.

Why Choose a Direct Pallet Wrapping Machine Manufacturer?

Hidden middleman fees increase costs 20-50%. A Brazilian buyer discovered his machine passed through three resellers.

Direct manufacturers offer custom modifications without extra charges. This eliminates design limitations caused by generic reseller stock. You get warranty protections directly.

4 Customization Benefits

Precision Engineering

Modify turntable sizes for oversized pallets

Climate Adaptations

Upgrade motors for -20°C freezer warehouses

Safety Features

Add infrared barriers for hazardous zones

Smart Integration

Enable IoT connectivity for maintenance alerts

You might need specialized roller conveyors. We redesigned three machines last quarter for pharmaceutical clients requiring dust-proof casings. Share your facility layout. Our engineers create 3D design proofs within three business days. Direct access solves unique operational challenges cheaply.

How to Get the Best Pallet Wrapping Machine Wholesale Deals?

Bulk buyers often receive inferior machines. I recently inspected a "discount" batch with downgraded PLC controllers.

Negotiate wholesale discounts when ordering 3+ units simultaneously. Confirm all machines undergo individual pre-shipment testing and include identical configurations.

Wholesale Cost Factors

Avoid suppliers who substitute components in bulk orders. This damages production uniformity.

Quality vs. Discount Balance

| Feature | Standard Option | Upgrade Impact |

|---|---|---|

| Motor System | Taiwan OEM | German parts +$220 |

| PLC Controller | Basic model | Touchscreen +$300 |

| Frame Material | Standard steel | Reinforced +$180/machine |

We recommend prioritizing core components over cosmetic extras. Verified steel tensile strength prevents frame warping during continuous operation. Our Vancouver wholesale client saved 14% through consolidated sea shipping. Request CIF quotations for most transparent duty costs. Compare warranties – premium components often extend coverage periods. Bulk inquiries gain faster responses through our main sales channel.

Conclusion

Secure pallets reliably. Buy directly from verified manufacturers. Customized solutions beat generic machines every time. Our decade-long exports guarantee this.