Finding reliable industrial equipment manufacturers can feel overwhelming. As a factory director at Myway, I’ve seen clients lose money to suppliers cutting corners. Trust matters deeply for your operations and profits.

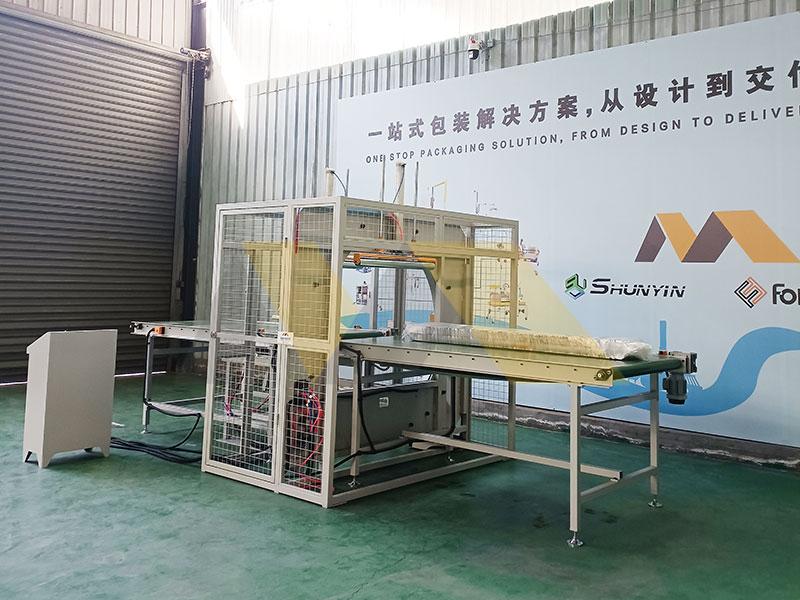

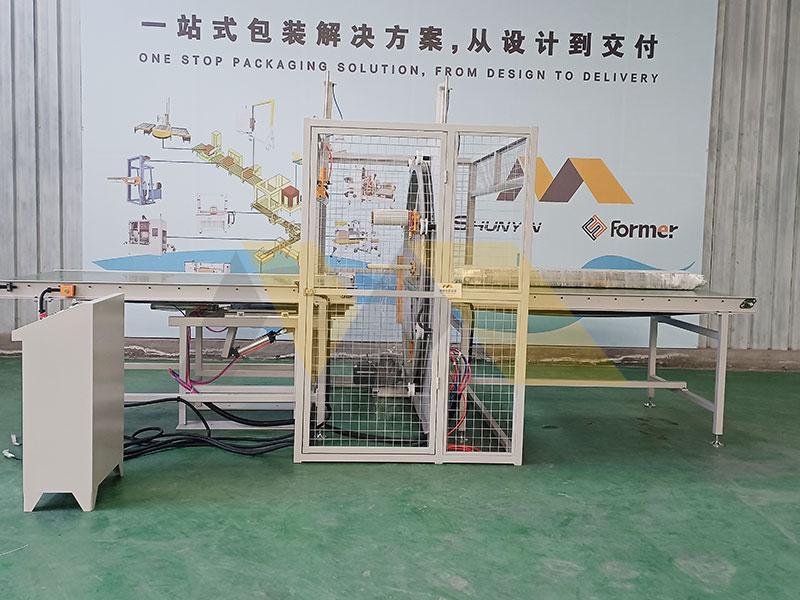

Leading horizontal wrapping machine producers in China combine rigorous quality certifications, comprehensive customization, and export-ready engineering – we hold ISO9001, CE, and UL standards to eliminate trade risks while delivering 30% cost savings through direct factory pricing and vertical manufacturing control.

You might wonder how Chinese machinery stacks up against competitors. Let’s explore four key models meeting global demands.

What is an Automatic Horizontal Wrapping Machine?

Many buyers hate inconsistent product packaging. Imagine your goods arriving damaged because corners weren’t sealed properly. Heat-seal failures ruin customer trust instantly.

These machines encase products horizontally using automated film feeding and sealing systems – our models feature PLC controls with adjustable rotation speeds up to 40rpm for stable 500+ packages/hour output, reducing labor costs by 60% while handling boxes from 20cm to 2m.

Core Components and Operation Logic

I’ll break down why the internal design affects your ROI. Clients often focus only on speed but regret skipping maintenance access. Let’s dissect the critical sections:

| Component | Function | Failure Impact |

|---|---|---|

| Film Carriage | Pre-stretches film to reduce usage by 35% | Increased material waste |

| Rotary Arm | Spins product horizontally for even coverage | Uneven load stability |

| Programmable Controls | Set film tension/packaging formats | Downtime for format changes |

The workflow starts with film pre-stretch, minimizing rips during high-speed wrapping. Sensors detect product dimensions to adjust arm movements automatically – we use German Bosch sensors after seeing competitors’ low-cost alternatives jam within months. One bakery client ran wrappers 24/7; their throughput increased 75% once we reconfigured the grippers for moist dough boxes.

For perishable goods, humidity-resistant stainless steel frames prevent corrosion without raising prices. Ask us to demonstrate different film types during trial sessions. Send your box samples via DHL; we simulate actual conditions in our testing lab at no cost.

How Does a Pipe Horizontal Wrapping Machine Secure Cylindrical Items?

Tubes and pipes rolling off conveyors frustrate warehouse crews. Traditional wrapping creates film gaps where moisture seeps in. Rusty pipes cause construction delays and liability claims.

Specialized rollers and tapered clamps secure cylindrical items during rotation – our designs wrap pipes from 3cm to 90cm diameter with variable torque control, eliminating slippage while reducing shipping damage claims by 80%.

Engineering Against Common Hazards

Dropped loads cost Canadian distributors over $15,000 monthly in replacements. Unlike standard models, pipe wrappers need:

- Gripping Systems: V-shaped rollers with rubber grips prevent scratches while holding weight

- Balancing Algorithms: Counterweights adjust for uneven mass distribution

- Film Adhesion: Heating elements activate glue layers instantly on non-porous surfaces

We filmed trials showing frozen pipes (-30°C) wrapped successfully using low-tack films. Check these videos before purchase and discuss surface textures with me directly. Many clients add protective bubble layers using our retrofittable modular attachments. Last month, we shipped three models with Arctic-grade lubricants for Manitoba operations.

What Are the Advantages of Orbital Wrapping Machines?

Employees hate twisting around heavy pallets. Back injuries skyrocket with manual methods. Unstable loads toppling in transit create insurance nightmares.

Equipment rotates film around stationary pallets instead of moving goods, eliminating product shifting risks – our units handle 3-ton pallets at speeds up to 50 revolutions/minute, securing goods in 90 seconds with up to 250% pre-stretch capability reducing film expenses by 20%.

Optimizing Facility Layouts

Space constraints determine operational efficiency. These machines operate effectively in just 10m². Compared to turntable systems:

| Feature | Orbital Wrapper | Turntable Wrapper |

|---|---|---|

| Movement Type | Ring circles product | Product spins |

| Vibration Risk | Near zero (item still) | High (shifting load) |

| Power Usage | 30% less | Standard |

Our compact X7 model fits narrow warehouse aisles using collapsible rails. For battery factories, we added copper-proof film guides after a client reported sparks from contact during trials. Share your floor plans via WhatsApp at WhatsApp us direct – we’ll build a 3D simulation proving clearance requirements.

Can Stretch Film Horizontal Wrapping Machines Cut Material Costs?

Overspending on film feels unavoidable. Suppliers hide how inefficient roller setups increase usage. Blown seals from cheap components waste entire rolls.

Integrated pre-stretch technology elongates film molecules before application – our modular systems achieve 500% stretch rates through infrared thermal controls, lowering annual film budgets 30% while eliminating breaks with patented Japanese tension sensors.

Maximizing Film Efficiency Without Compromising Integrity

During Vancouver tradeshows, distributors showed me failed machines wasting 8kg rolls every hour. Film performance relies on:

- Temperature Gradients: Prevents crystallization during stretching

- Load Sensors: Automatically reduce tension for fragile items

- Layer Calibration: 8-micron films require different roller pressures than 12-micron

See comparison reports between film brands and get genuine replacement parts shipped air freight within five days. I caught suppliers substituting Chinese sensors with uncertified copies – we now provide serial-number-authentic parts tracking.

Conclusion

Trustworthy Chinese manufacturers like us offer customization, quality assurance, and cost control across horizontal wrapping systems. Choose partners willing to validate claims.