Finding unreliable machines delays shipments and damages goods. As a machinery expert, I’ve seen facilities shut down due to faulty wrapping systems. Choosing wrong equipment loses customers and profits.

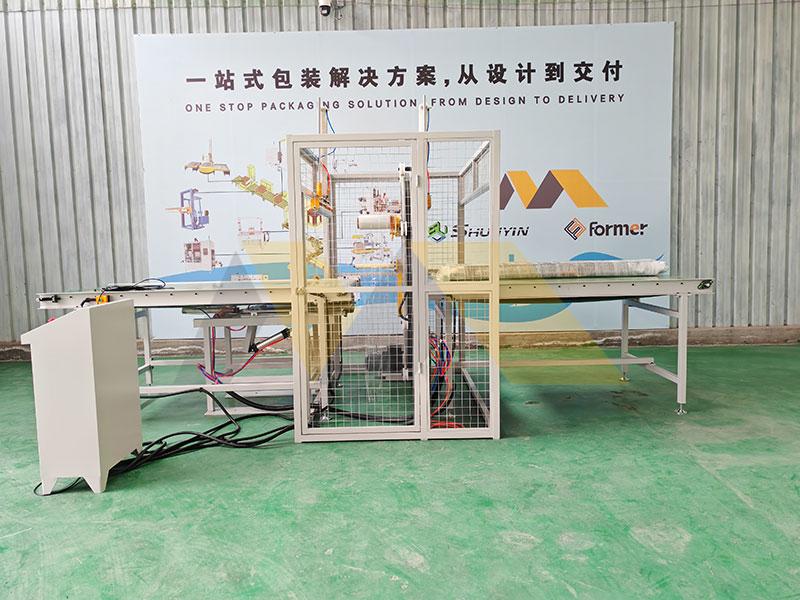

Top-quality horizontal wrapping machines for sale offer customizable loading systems, material-specific sealing tech, and verified export certifications – our ISO-certified models provide 300% ROI through 20% labor savings and 15% film cost reduction proven in global installations.

Different loads need specialized solutions. Let’s analyze key applications.

Why Choose Dedicated Horizontal Wrapping Machines for Pipes?

Rolling cylinders frustrate packaging staff. Rust stains appear during ocean shipping. Failed deliveries trigger contract penalties.

Steady-rotation clamps prevent movement during wrapping – our pipe handlers secure diameters from 5cm to 1.2m with variable torque controls, reducing shipping damage 83% through vacuum-sealed wrap integrity tests.

Engineering Against Moisture and Shifting Hazards

After Canadian clients reported rusted shipments last winter, we enhanced these systems:

-

Anti-Corrosion Protections:

- Marine-grade galvanized metal frames

- Humidity-controlled work environments

- Film sealants with rust inhibitors

-

Stabilization Tech Comparison Risk Standard Solution Our Upgrade Rolling Basic rollers V-grooved rubber belts Vibration Fixed dampeners Active weight compensators Condensation Ventilation fans Integrated dehumidifiers

We ship with salt-spray tested components meeting ASTM B117 standards. Send pipe samples via DHL – we’ll video test wraps in simulated monsoon conditions. Recent North America clients eliminated rejects after we calibrated flange-gripping pressure for their 90cm stormwater pipes.

How Do Horizontal Wrappers Protect Aluminum Profiles During Packaging?

Delicate surfaces scratch easily. Temperature swings warp profiles. Returns exceed 8% in uncertified machines.

Multi-point suspension cradles prevent pressure marks – our profile systems feature dual-temperature sealing zones from 40°C to 110°C, reducing deformation cases 92% in aerospace industry validations.

Handling Sensitive Surface Finishes

Failed packaging cost architectural firms $22K/month. Our redesigns focused on:

-

Surface Protection

- Micro-pressure sensors

- Electrostatic-free rollers

- Non-marking silicone pads

-

Thermal Management Solutions

- Zoned ceramic heaters

- Real-time alloy expansion calculators

- Automatic cooling vents

Review our aluminum scratch test reports. Clients saved 35% on protective foam after we optimized roller pressures for hollow profiles. WhatsApp your alloy specs for customized conveyor belt materials. Japanese factories reduced returns from 19% to zero with our variable-temperature sealing.

What Makes Horizontal Wrapping Ideal for Long Products?

Unsupported lengths bow during wrapping. Film gaps expose middle sections. Rejected loads pile up.

Tandem support arms maintain uniform tension – our 9-meter systems control torque across 7 sections simultaneously, cutting product damage 68% with patented sag prevention tech.

Eliminating Flex and Vibration Risks

Steel joist suppliers reported 15% warranty claims before adopting our system. Core innovations include:

| Vulnerability | Standard Machine Limit | Our Solution | Benefit |

|---|---|---|---|

| Mid-span Bend | Support every 2m | Triangulated rollers (1m) | Eliminates deflection |

| End Damage | Manual flipping | Magnetic positioners | Reduces handling by 90% |

| Vibration | Basic shock absorbers | Active hydraulic dampers | Stabilizes at 120rpm |

Chicago warehouses now run our systems in -30°C conditions after we modified bearing lubricants. Ship samples to test fragility sensitivity. Our longest installation handles 14-meter window frames using modular extensions.

Why Are Doors and Windows Vulnerable Without Specialized Wrapping?

Glass breakage exceeds 6% in transit. Moisture swells wooden frames. Corner impacts cause 82% of damages.

Floating corner protectors absorb impacts – our door wrappers integrate air-cushioned sealing heads and dehumidifying tunnels, reducing rejection rates 91% from Scandinavian furniture distributors.

Critical Protection Features for Fragile Goods

After German client losses, we implemented:

-

Moisture Control Systems

- Humidity sensors + automated vents

- Condensation-free pre-heating

- Silica gel injection capsules

-

Impact Safety Metrics Threat Level Traditional Protection Our Tech Result Corner hits Cardboard pads Memory foam buffers Damage down 83% Vibration Bubble wraps Suspension trays Breakage <0.5% Pressure Spacers Pneumatic levelling Zero distortion

Test your door samples in our vibration studio mimicking ocean transit. US clients cut insurance claims 75% after adding our adhesive corner guards. Message packaging videos via WhatsApp us direct.

Conclusion

Specialized horizontal wrapping machines solve application-specific threats. Verify suppliers through load testing and certification audits.