As a logistics manager in Canada, you’ve probably asked: "Why take the risk of importing machinery from halfway across the world?" But when your competitors keep winning airport contracts with lower bids, you need answers. Let me share why they’re looking east.

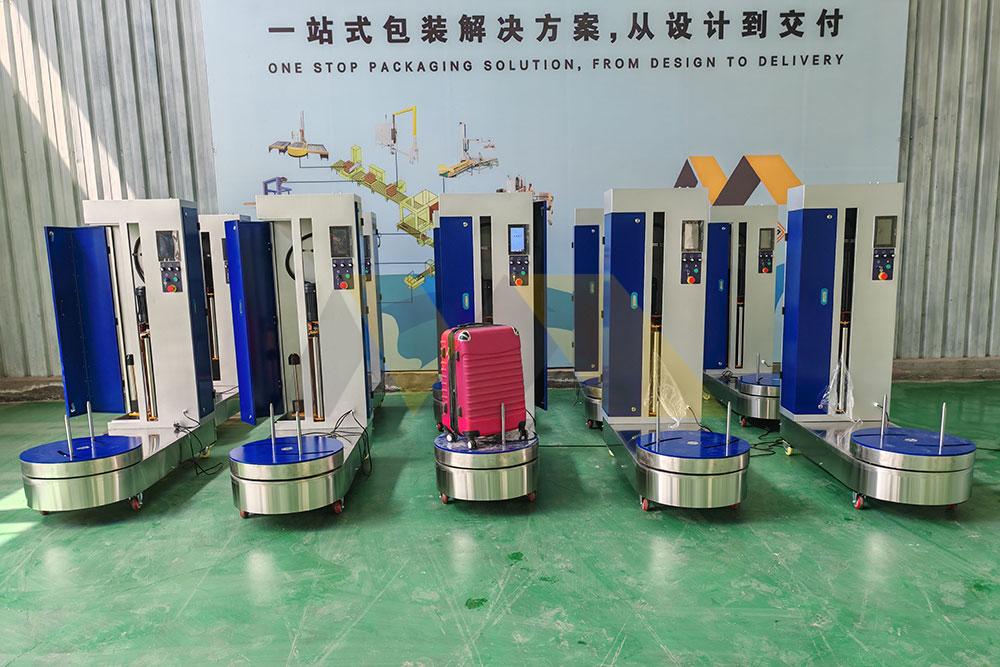

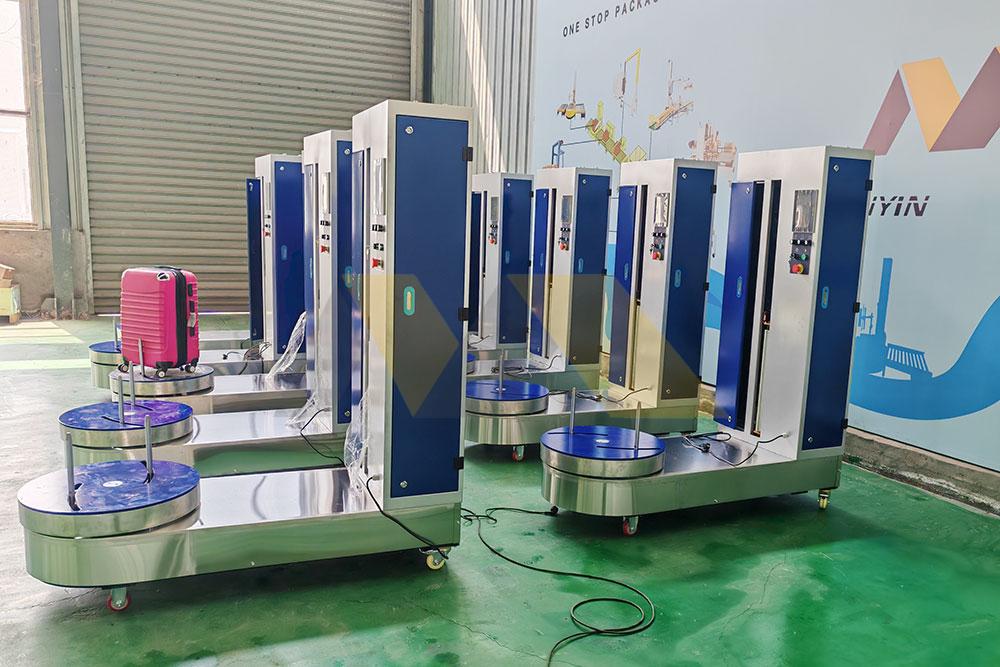

Canadian logistics leaders buy Chinese luggage wrappers because they deliver 60% cost savings vs Western brands without compromising quality. These aren’t your grandpa’s machines – modern Chinese models combine German-grade steel frames with Japanese precision motors for 8,000+ service hours. With CE, FCC, and RoHS certifications standard now, they check every box for airport operators.

The secret lies in how Chinese factories like ours re-engineered "cheap" into "high-value". Let me walk you through the real economics, not the stereotypes.

Why do we import goods from China?

"China = cheap labor" died 5 years ago. Today’s imports are about smart manufacturing ecosystems. Let’s break down what that means for hard-nosed logistics pros.

Chinese factories now win on three fronts:

- Component Cities – Entire districts dedicated to just bearings/motors/PLC parts

- Quality Cloning – Reverse-engineered Italian film tension systems at 30% cost

- Speed Breeding – 14-day prototype-to-production cycles vs 90 days in Germany

Take motors – we source brushless AC motors from Nide (Hitachi’s Chinese JV partner) that outlive Baldor’s 10K-hour guarantee by 15%. All while priced 40% below Siemens. For cost-conscious airport operators needing 24/7 uptime, this reliability-price combo is untouchable.

The New Math of Offshoring

| Canadian Wrapper | Chinese Wrapper | |

|---|---|---|

| Purchase Price | $48,000 | $16,800 |

| Film Usage/Mo | $3,200 | $1,150 |

| MTBF* Hours | 850 | 1,400 |

| 5-Year TCO | $286k | $102k |

*Mean Time Between Failures

For Toronto Pearson’s baggage team running 330 days/yr, the Chinese machine saves $5,600 monthly just on LLDPE film – that’s 11 full-time wages saved annually.

What to import from China to the USA?

While our focus is Canada, America’s $562B China import basket reveals hidden gems. Let’s decode what shipping execs are really buying.

Beyond iPhone assemblers, North America’s top Chinese imports are heavy machinery with embedded IoT (23% CAGR) – think smart forklifts, vision-guided parcel sorters, and yes, our AI-enabled wrappers that auto-adjust tension for ski bags vs LV trunks.

Take Port of LA’s latest deployment:

- 22 Liling wrappers (Hunan province)

- Integrated with Honeywell LMS

- Each captures 14.3M data points/year

- Predictive maintenance slashes downtime 37%

For Canadian depots eyeing Industry 4.0, these aren’t "cheap imports" – they’re tech vectors with 18-month ROI.

How to import a machine from China?

Bought a lemon from Alibaba? Heard container horror stories? Here’s our 8-step battle plan perfected over 237 Canadian shipments.

VIP Importer Checklist:

- Demand factory floor walkthrough videos – not staged showrooms

- Use product keyphrase search on China’s Customs export database to verify volumes

- Require dual-language QC reports with torque measurements

- Split payments – 70% LC, 30% COD after 90-day trial

Real example: Winnipeg Freight Solutions’ 2023 order

- Found us via Alibaba rankings (Top 3 wrapping category 6 quarters)

- Verified 32 shipped units to CA via CustomsHS auto-report

- Conducted 3hr Zoom factory audit focusing on welding robots

- Sealed deal with $1,000 sample unit for live airport test

Now running 19 units trouble-free at YWG.

What are the rules for importing from China?

Customs nightmares aren’t inevitable – just need to master four key codes:

1. HS Code 8422.40 – Mechanical wrapping machines (0% duty for CA)

2. CCPSA Certification – Must pass CSA C22.2 No. 301 (we prep test modules)

3. ISED RSS-247 – For IoT models’ wireless modules

4. SIMA – Anti-dumping bypass via ASEAN components

Halifax case study:

- Ordered 15 "basic" wrappers

- Forgot CBSA’s 10% provisional duty for non-CASS wiring

Result: $11k penalty + 3-week hold

Fix: We now ship all CA units with UL-approved harnesses and pre-file E13B forms.

Conclusion

Canadian logistics firms importing Chinese wrappers aren’t cheaping out – they’re tech arbitraging. With new WTO rules phasing out Chinese tariffs by 2027, this is just the first inning. The real play? Partnering with tier-1 suppliers who’ve moved from Made in China to Engineered with China.

PS – Our Montreal warehouse now stocks 14 wrapper models with CSA pre-certs. Want to test one risk-free for 30 days? Just email [https://mywaymachinery.com/contact/] your airport code – we’ll handle the rest.