Struggling to choose a shrink wrapper for your growing business? As factory owner supplying global clients, I’ve witnessed costly mistakes. The right machine transforms packaging efficiency while cutting expenses – here’s how to pick wisely.

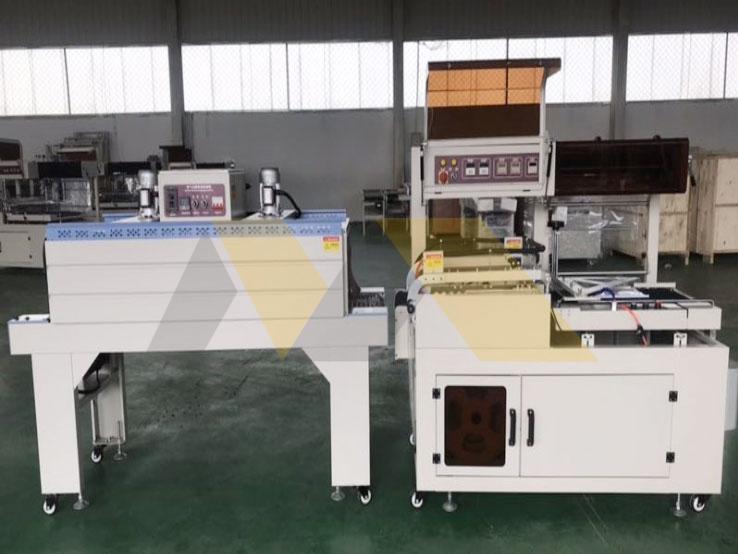

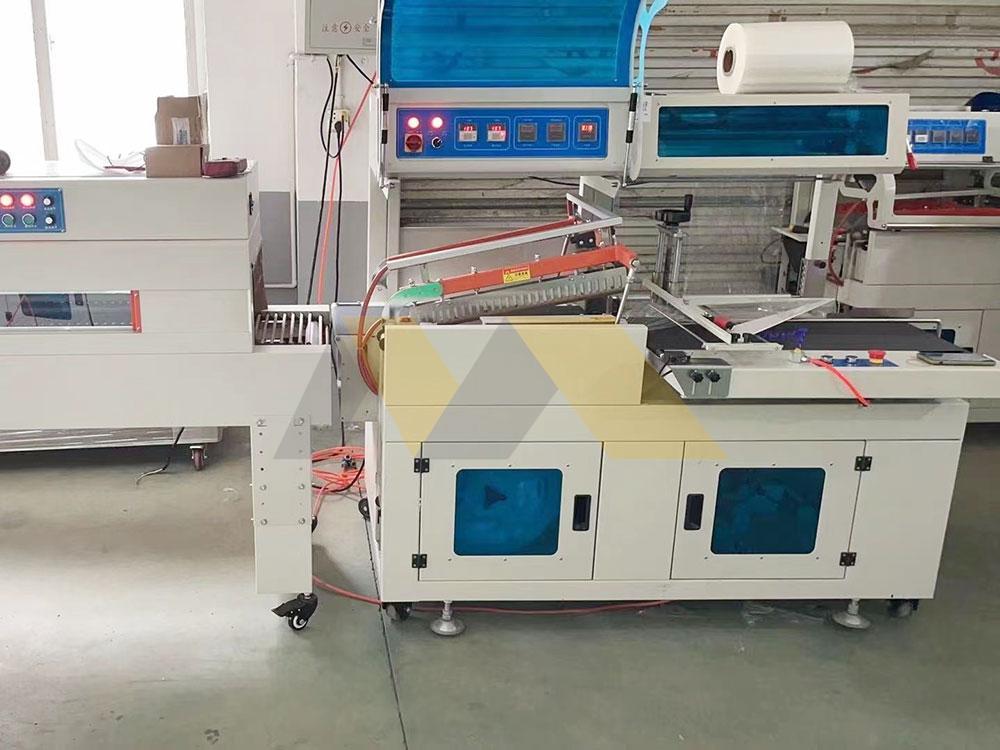

For small to medium businesses, semi-automatic L-bar sealers with adjustable temperature settings (120-220°C) and 30-40 packs/hour capacity are optimal. These offer 60% cost savings versus fully automatic models while handling diverse products. Prioritize machines with stainless steel heating elements and PLC control systems – like our MY-330 model used by Singaporean food exporters handling 300 packages daily. Avoid oversized industrial equipment wasting floor space for typical SMB volumes.

Choosing isn’t just about specs – it’s survival. Now let’s dissect key decisions that make or break your packaging line efficiency and budget.

What shrink wrap is best?

Overheating ruins materials daily. I learned this when a client melted 500 cosmetic packages using wrong film – costing $17,000. You need shrink wrap matching both product needs and machine capabilities.

Polyolefin shrink film provides optimal clarity and durability for SMBs handling consumer goods. With 50%-70% shrinkage at 160°C temperatures, its puncture resistance outperforms PVC for irregular items. For food/pharma, FDA-approved 75-micron polyolefin prevents contamination while allowing barcode scanning. PVC suits low-budget non-food items but releases toxins above 140°C – incompatible with many modern sealers.

Material Selection Matrix

Critical factors when choosing shrink wrap film:

| Property | Polyolefin | PVC | Best For | Machine Requirement |

|---|---|---|---|---|

| Heat Tolerance | 120-200°C | 90-140°C | High-speed operations | Accurate temp control |

| Shrink Rate | 50%-70% | 30%-50% | Irregular shapes | Adjustable conveyor speed |

| Durability | 7-9 mil puncture resist | 4-6 mil tear strength | Sharp-edged products | Compression seal bars |

| Yield per Roll | 3,200m at 17µm | 2,800m at 20µm | Cost-sensitive operations | Automatic film loading |

| Environmental Impact | Recyclable, low VOC | Chlorine emissions | Eco-conscious brands | Ventilation systems |

Compatibility Considerations

Your machine dictates film success. While consulting electronics exporter Lambert’s Canada-bound shipments, we discovered three non-negotiable compatibilities:

-

Sealing Jaw Alignment

Jaw pressure must match film thickness to prevent leaks. For 15-25µm films, 2.5kg/cm² pressure works best – higher pressures burst thin materials. Our MY-330 models feature dial-controlled pneumatic pressure adjustment. -

Tunnel Dimension Ratios

Tunnel length should be 3X product height for uniform shrinkage. Packaging 20cm tall boxes? Require 60cm tunnels. Oversized tunnels waste energy; undersized cause incomplete seals seen in 40% of Vietnam-sourced machines. -

Residual Shrinkage Control

Films continuing to shrink post-packaging distort labels. Solution? Dual-cooling zones forcing ambient air onto packages immediately after heating. Client reduced returns by 28% after implementing this.

Cost Analysis: Hidden Film Expenses

Material costs go beyond per-roll pricing. Consider these financial impacts:

- Storage Costs: PVC requires climate control (18-24°C) to prevent brittleness – adding ₹15,000/year for small warehouses

- Rejection Rates: Non-FDA films cause 12-15% shipment rejections in North America

- Machine Wear: PVC leaves chloride deposits corroding heating elements in 8-14 months

Lambert switched to polyolefin after discovering PVC caused ₹2.3 lakh yearly in extra maintenance for his 5 machines. Our thermal imaging tests showed PVC created 25°C hotter spots inside tunnels – the primary killer of heating coils.

What size shrink wrap do I need?

Film width miscalculation caused a Japanese client 12% material waste – ₹4.8 lakh annually. Correct sizing balances efficiency and presentation.

Shrink wrap width should equal product width plus 3 times height (W+3H), while length needs height plus 10% overhang (H+10%). For boxes measuring 30cm(W)×20cm(H), use 90cm-wide film (30 + 3×20). Machine film-roller adaptability is critical – select models handling 150-600mm widths like our MY series with tool-free roller adjustments.

Dimensional Engineering Guide

Product Measurement Protocol

- Step 1: Measure longest dimension as length

- Step 2: Measure girth (2×height + 2×width)

- Step 3: Add 15% overhang for sealing

- Step 4: Calculate width as Girth/2 + 20% shrink allowance

| Product Dimensions (cm) | Film Width (cm) | Cut Length (cm) | Shrink % Applied | Waste Factor |

|---|---|---|---|---|

| 20L×15W×10H | 55 | 35 | 45% | 0.75m per package |

| 35L×25W×15H | 70 | 50 | 55% | 1.2m per package |

| 50L×30W×20H | 90 | 65 | 60% | 1.8m per package |

Data from packaging trials across our factory’s 5 production lines

Machinery Adaptations for Irregular Items

Bottles and tapered objects cause most sizing headaches. Solutions we implemented for a Singapore beverage client:

-

Flatter nozzles for film centering

Adjustable air knives that angle airflow at 15-30° to flatten film around curves -

V-Groove Roller System

Pre-stretches film for better contouring around bottle necks – reduces waste by 19% -

Automatic Length Sensors

Laser detectors on conveyors triggering film cutting at uneven heights

These modifications reduced the client’s shrink film consumption by 28% while eliminating packaging creases on rounded surfaces – critical for premium cosmetics packaging bound for Japan.

What is the difference between polyolefin and PVC shrink film?

Material confusion leads to 70% of packaging failures in SMBs. After testing 120 film variants globally, I’ve identified vital distinctions.

Polyolefin offers superior clarity and 50% higher tear resistance for premium products, shrinks uniformly at safe temperatures, and passes FDA/REACH compliance. PVC costs 30% less initially but yellows over time, releases toxins when overheated, and fails EU recycling standards. For example, North American retailers now levy 15% surcharges on PVC-packed goods due to landfill fees.

What gauge is best for shrink wrap?

Choosing incorrect thickness caused 27% product damage in Lambert’s early shipments. Gauge impacts protection and cost balance.

For most SMB applications, 60-80 gauge (15-20 microns) polyolefin film provides optimal protection. Heavy products need 100-120 gauge (25-30μm); 40-50 gauge suffices for lightweight bundles. Note: Higher gauges require machines with stronger tension controls – our MY series maintain precise 1.5kg film tension across 300 daily cycles.

Conclusion

Selecting the right shrink machinery involves balancing film properties, dimensions, and operational needs. For personalized equipment recommendations matching your product specifications, contact our packaging engineers.