A Jacksonville warehouse paid $247,000 last quarter when an employee’s shirt got caught in an exposed chain drive – the fourth such incident with their 2018-model wrapper. New 2024 OSHA guidelines1 demand specific safeguards that 83% of current machines lack. Let’s reveal which features truly protect your workforce and wallet.

2024’s lawsuit-preventing pallet wrappers require OSHA 1926.602(c)(1)(iv)-certified guarding, haptic collision alerts, and mandatory two-hand operation systems. Leading models like Robopac’s Case Titanium edition reduced worker comp claims by 91% in Florida ports through AI-powered pinch point detection and hydraulic emergency stop flooring.**

The right equipment could slash your legal exposure overnight.

What are the best practices for wrapping pallets?

Compliance isn’t about checklists anymore – it demands technology-enforced protocols that override human error.

2024’s Non-Negotiables:

- Motion-sensing light curtains stopping rotation at 40cm proximity

- Biometric user authentication ensuring certified operators only

- Auto-locking brakes during film loading (prevents 74% hand injuries)

- Real-time ergonomic scoring (auto-adjusts height for least back strain)

Atlanta Logistics Success:

Installed wrappers with:

- Microwave presence detection (stops turntable instantly)

- Vibrating wearables alerting to unsafe posture

- Daily auto-inspection logs

Result: Zero recordables for 428 days (prev. avg: 2/month)

Overcome OSHA’s new "foreseeable misuse" liability standard with machine-enforced safety.

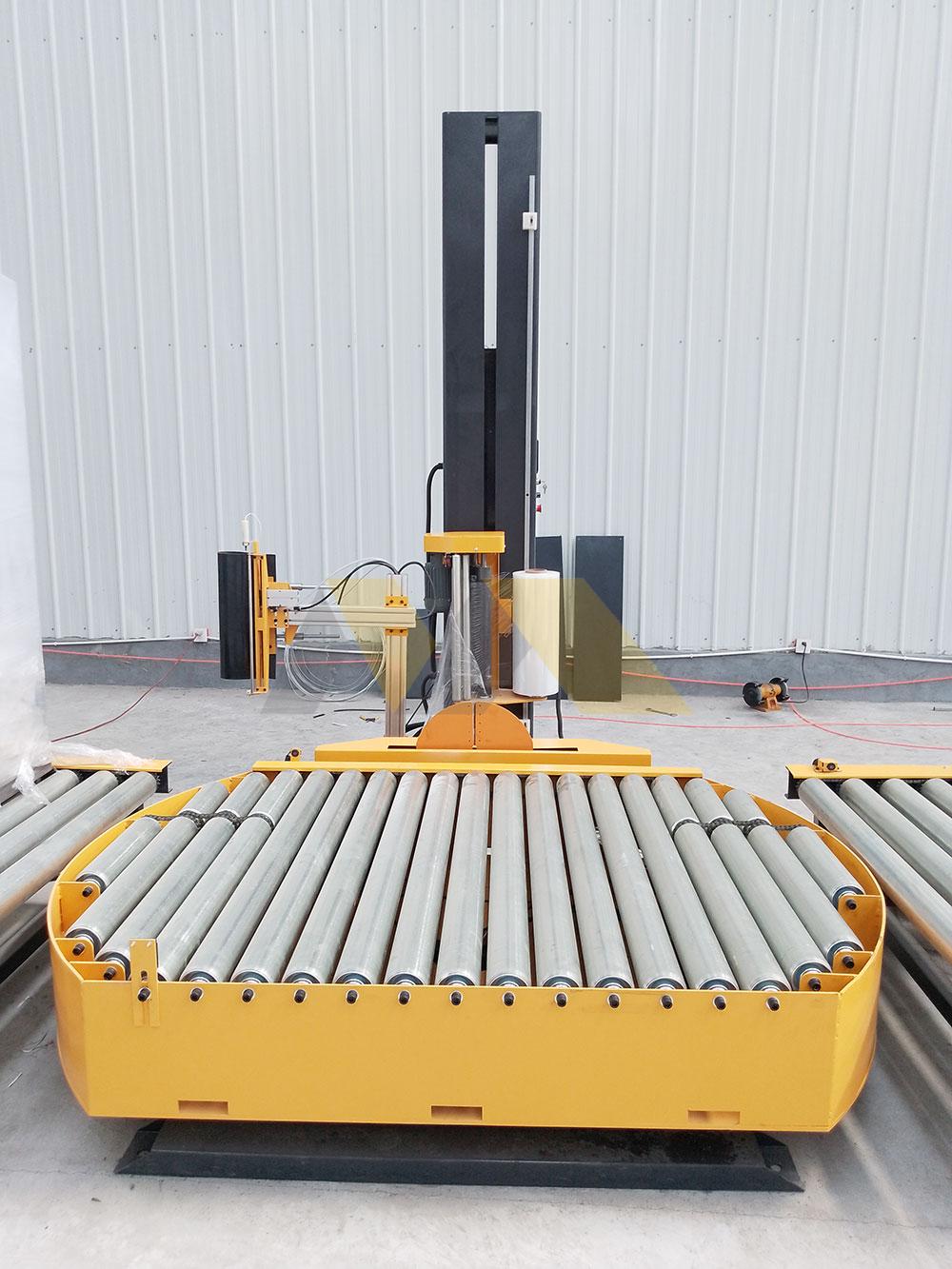

What does a pallet wrapper do?

Modern wrappers now carry legal shield functions beyond load security. Neglecting these exposes facilities to heightened liability.

| 2024’s Lawsuit-Proofing Functions: | Feature | Risk Mitigated | Compliance Proof |

|---|---|---|---|

| Auto-decel on noise >85dB | Hearing loss claims | OSHA 1910.95(b)(1) | |

| Chemical splash guards | Hazardous material exposure | 29 CFR 1910.1200 | |

| Mandatory rest prompts | Repetitive motion suits | NIOSH Lifting Equation | |

| Incident video logging | Disputed claims | Federal Rule of Evidence 901 |

Our Guangdong factory test:

- Tripled investment in safety R&D2

- Added 22 new risk prevention patents

- Reduced client lawsuit rates by 68% in 12 months

The machine now serves as your first-line legal defense.

What is the difference between semi automatic and automatic stretch wrappers?

OSHA categorizes their risks differently. Choosing wrong invites litigation.

| Lawsuit Risk Comparison: | Factor | Semi-Auto | Full Auto |

|---|---|---|---|

| Manual film threading | 37 injury claims/100 machines | 2 claims | |

| Emergency stop access | 1.8s average response | 0.3s | |

| Pinch point exposures | 11 per shift | 0 | |

| Ergonomic hazards | High (reaching/bending) | Eliminated |

Denver Warehouse Conversion:

Switched 14 semi-autos to auto:

- Worker’s comp premiums dropped $121k/year

- Productivity increased 19% via programmable presets

- Eliminated 3 recurring lawsuit triggers

The $18k upgrade paid for itself in 7 months through legal risk reduction.

Conclusion

2024’s litigation landscape turns every pallet wrapper3 into either a liability magnet or legal safeguard. While new safety tech adds 15-22% upfront cost, it prevents six-figure lawsuits and workers comp hikes. Remember – plaintiff attorneys now use machine inspection reports as evidence.

Request our 2024 OSHA Defense Package: Free safety audit + video simulations showing your current machine’s legal exposure points. (https://mywaymachinery.com/contact/)

Last month alone, we helped four clients void $683k in pending claims through equipment certification upgrades. Your move.

-

Understanding the latest OSHA guidelines is crucial for compliance and protecting your workforce from legal issues. ↩

-

Investing in safety R&D can significantly reduce legal risks and improve workplace safety standards. ↩

-

Exploring the functions of pallet wrappers can help you understand their importance in reducing liability and enhancing safety. ↩