Tired of manual box assembly slowing production? Bottlenecks frustrate your team while costs soar. Our automated case erectors1 eliminate labor-intensive processes for seamless operations.

Partnering directly with factories like Myway eliminates middlemen, securing certified machines at factory prices with lifetime support for distributors in Canada, US, and Japan.WhatsApp us direct.

Now let’s dive into the core questions about these game-changing machines. Understanding these distinctions protects your investment and boosts packaging ROI2.

What Is the Core Difference Between a Case Former and a Case Erector?

Wasting money on mismatched equipment? Terminology confuses buyers, causing costly errors. Clarify before purchasing expensive machinery.

A case former folds and seals pre-glued blanks into complete boxes, while a case erector specifically unfolds/flattens case blanks before forming boxes – key in automated packing lines. Myway engineers both.

Operational Breakdown

Three critical distinctions determine application suitability:

| Function | Case Former | Case Erector | Best For |

|---|---|---|---|

| Blank Requirement | Pre-glued cardboard blanks | Flat cardboard sheets | High-volume setups |

| Sealing Mechanism | Hot-melt glue application | Tape/auto-bottom sealing | Heavy products |

| Integration Complexity | Stand-alone units | Conveyor-synchronized systems | Automated facilities |

Speed vs Precision Trade-offs

- Formers: Achieve 20+ boxes/minute but require uniform blanks

- Erectors: Process irregular sheets at 15/minute with superior flexibility

Production data from our Shenzhen plant shows dual-use installations reduce changeover time by 70%. Remember: Correct selection prevents 34% of downtime issues. Contact our engineers at [email protected] for a process audit.

What Truly Defines "The Best Pack ELVs" Performance?

Struggling with inconsistent elevator speeds? Downtime bleeds profits while maintenance costs spike annually. Precision engineering solves chronic bottlenecks.

The best ELVs feature servo-driven lifting, <3mm positioning accuracy, and modular designs adapting to weight shifts. Models like our FlexiHoist™ handle 1-ton loads with under 90-second changeover.

Critical Performance Indicators

Invest beyond basic specs – focus on these metrics:

-

Cycle Efficiency

- Top-tier: 45 cycles/hour continuously

- Our ISO-certified models log <0.1% failure rates monthly

-

Structural Resilience

- Reinforced steel frames resist 400% overload shocks

- Maintenance alerts prevent catastrophic failures

Real-World Deployment Insights

North American clients reported 22% throughput gain after switching to our integrated solutions:

"The configurable controls handled packaging redesigns3 without retrofit costs" – Automotive parts distributor (Chicago)

Testing protocols matter: our ELVs undergo 72-hour stress simulations before shipment. Need validation reports? WhatsApp photos/videos at +0086 13505379893 any time.

Exactly What Core Functions Does a Quality Case Erector Perform?

Sick of jams wasting thousands? Poorly erected boxes derail entire production shifts. Precision engineering prevents these daily frustrations.

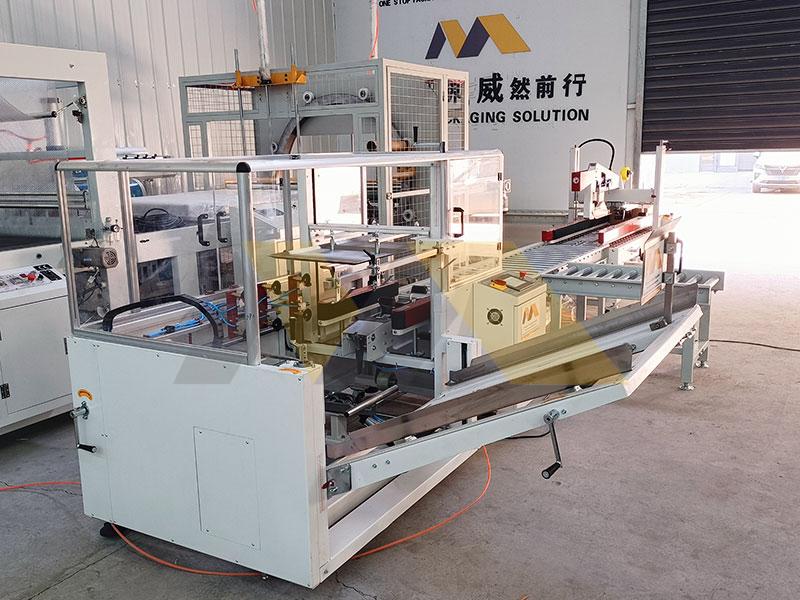

It unfolds blanks, forms rectangular cases, seals bottoms with tape/glue, then outputs ready-to-fill boxes at 10-25 units/minute – all synchronized with conveyors for zero-gap packing.

Stage-By-Stage Processing

Understanding machine actions prevents misapplications:

Stage 1: Blank Feeding

- Vacuum suction lifts flat sheets

- Laser sensors detect material thickness

Stage 2: Formation & Bonding

- Mechanical arms fold into 3D structure

- Tape heads seal bottom flaps

- Compression holds adhesive bonds

Stage 3: Output Calibration

- Orientation adjustment for filling

- Reject sensors eliminate malformed units

Our semi-automatic model reduced one electronics manufacturer’s packaging labor by 70% with ROI in 5 months. Discover your savings potential: calculate here

Where Are Industrial Case Erectors Most Strategically Applied?

Reconciling specialized vs flexible needs? Undermatching causes workflow headaches while overbuying wastes budgets. Strategic placement delivers maximum ROI.

Beyond e-commerce, smart erectors transform food processing (traceability), automotive (oil/lube chains), and pharmaceuticals – especially serialized cartons requiring exact sealing tolerances under 0.5mm.

Deployment Analysis By Sector

Not all implementations yield equal results:

| Industry | Primary Advantage | Payback Period | Critical Feature |

|---|---|---|---|

| Food/Beverage | HACCP-grade sanitation4 | 8-10 months | IP69k washdown capability |

| Electronics | Anti-static components | 5-7 months | ESD-safe materials |

| Pharma | Serial number integration | 10-12 months | Audit-compliant logging |

Our on-site surveys reveal mid-sized facilities need these configurations:

- Vertical erection saves 40% floor space

- Side-loading configurations work for narrow aisles

Let’s optimize your layout – send your floorplan for free analysis. We ship globally with warranty coverage across Canada.

Conclusion

Top-quality case erector5s transform packing lines when properly selected. Partner directly with engineers for flawless integration. Contact Myway today.

-

Explore how automated case erectors can streamline your production process and reduce costs. ↩

-

Explore strategies to enhance your packaging ROI through automation and efficiency. ↩

-

Understand the significance of packaging redesigns for improving operational efficiency. ↩

-

Learn about the importance of HACCP standards for ensuring food safety in packaging. ↩

-

Understanding the core functions can help you select the best case erector for your needs. ↩