Finding reliable carton erector machines feels frustrating. Production lines stall. Manual folding wastes time. Your operation bleeds money daily. A solution exists for efficient packaging.

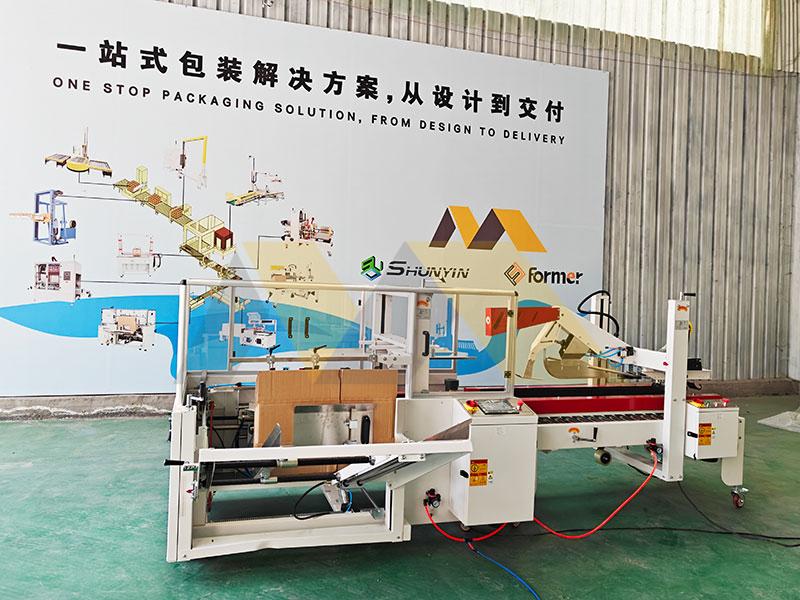

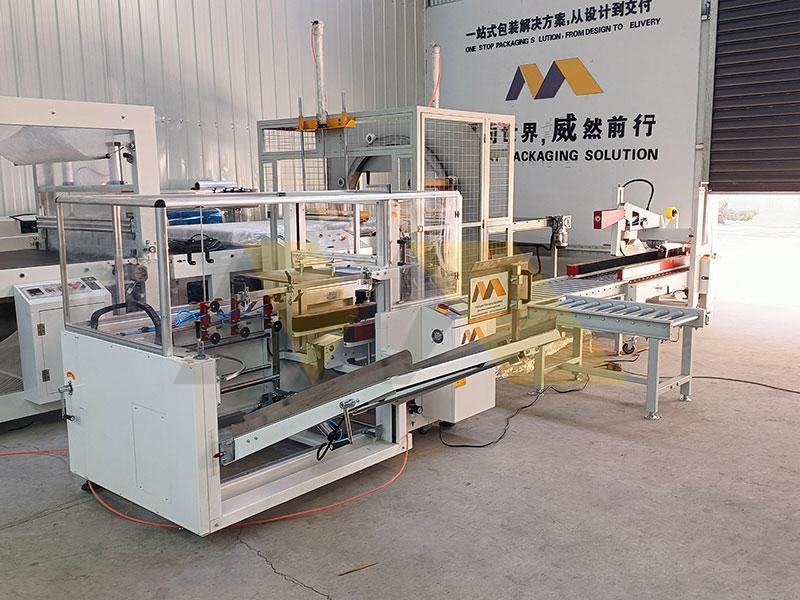

Top carton erector machines offer high-speed automation, precise case forming, and low maintenance costs. They transform cardboard blanks into boxes ready for packing. Ideal manufacturers provide customized solutions with comprehensive warranties, like our ISO-certified production lines in Jinan.

Stuck dealing with inconsistent suppliers? We solve machine breakdown headaches. This guide reveals where to source durable equipment without traps. Let’s explore critical buying factors before you commit.

What Determines Case Erector Machine Price?

Prices confuse buyers. Unexpected tariffs disrupt budgets. Cheap units break within months. Proper costing prevents surprise expenses.

Case erector pricing ranges from $18,000 to $75,000 based on speed (15-65 CPM), materials (stainless steel vs carbon steel), and automation level (manual feed to robotic integration). Bulk orders and customization impact final quotes significantly. Factory-direct purchases eliminate trader markups.

Consider these key price determinants:

| Factor | Entry-Level | Mid-Range | Premium |

|---|---|---|---|

| Speed | 15-25 cases/min | 30-45 cases/min | 50-65 cases/min |

| Frame Material | Powder-coated carbon steel | Reinforced carbon steel | Full SS304 stainless |

| Warranty | 1 year parts | 2 years onsite | 3 years global support |

| Energy Use | Standard 3-phase motor | Servo system (30% savings) | Regenerative energy recovery |

When our Canadian client ordered six units, port fees added 12% to his budget. Avoid this. Ship via LCL consolidation like we arranged for him. High-speed modules (above 45 CPM) require reinforced frames which cost $14K more but reduce vibration by 80%. Always confirm CE certifications – test reports matter. One buyer found fake ISO docs last month. Verify here: WhatsApp us direct for validation.

How to Identify Reliable Automatic Case Erector Manufacturers?

Manufacturer audits prevent nightmares. Broken promises delay projects. Hidden defects emerge after installation. Factory inspections verify real capacity.

Trustworthy manufacturers own production lines, hold CE/ISO certifications, and provide live video factory tours. Look for 10+ years export history to North America/Japan. Always request sample machine certifications before payment. Independent testing labs confirm safety compliance.

Deeper Verification Checklist:

🔍 Facility Authentication Steps

- Visit Alibaba Gold Supplier profiles (3+ years minimum)

- Demand ISO 9001 & CE test reports with QR verifications

- Check export records through third parties like Panjiva

⚙️ Production Capability Indicators

We operate five dedicated lines using German CNC systems. One client spotted inconsistencies in weld quality during our live video tour. Such details differentiate genuine factories from trading companies.

💼 Transparent After-Sales Terms

- Warranties must include overseas technician dispatch

- Confirm spare parts availability timelines

- Verify regional service partners

Avoid traders who can’t provide plant layouts or raw material invoices. Last month, a Singapore client nearly purchased rebranded machines until he video-called our workshop. See actual production: WhatsApp us direct.

What Makes an Exceptional Box Erector Machine Supplier?

Logistic failures stop operations. Delayed shipments cause revenue loss. Complex customs clearance increases headaches. Strong suppliers become partners.

Top suppliers handle customs clearance, provide DDP shipping terms, and maintain local spare parts warehouses. Exceptional ones offer machine operation training through English manuals/videos and maintain 24/7 remote support – proven across our Singapore/Japan clients.

Evaluating Supply Chain Excellence:

Documentation Mastery

- Proper HS code classification avoids customs holds

- Original COC/CEC certificates prevent port rejections

- Pre-shipment inspection records ensure functional units

Global Support Structures

- Local warehouses in CA/SG cut spare parts delivery times from months to days

- Remote diagnostic systems enable instant troubleshooting

- Online training portals with multilingual support

When we shipped 11 machines to Vancouver last winter, temperature-controlled containers preserved the PLC systems. Our client appreciated the moisture sensors we included. For complex shipments, we prepare packing lists with serialized parts. Stuck with customs? Get help: WhatsApp us direct.

Why Choose Specific Carton Opening Machines for Sale?

Generic openers misalign cases. Poor suction cups tear inserts. Incorrect box handling damages products. Machine compatibility ensures smooth integration.

Specialized carton opening machines handle specific box formats with precision suction and servo-driven position correction. Units with automatic size adjustment (15-140L) reduce changeover time by 70% compared to manual models. Customizable options include corner seal detectors.

Optimizing Your Setup:

Configuration Matrix

| Feature | Cosmetic Boxes | Food Packaging | Industrial Parts |

|---|---|---|---|

| Vacuum Strength | Low-suction (prevent dents) | FDA-grade grippers | High-force magnets |

| Changeover | Automatic template recognition | Tool-less adjustments | Manual locking pins |

| Add-ons | Fragile item sensor | Humidity-resistant seals | Anti-static rollers |

A Tokyo pharmaceutical client required humidity-controlled end effectors. Our solution reduced cardboard abrasion by 90%. Machines handling multiple sizes benefit from memory banks – we program 200+ presets onsite. Need box-specific guidance? Send dimensions: WhatsApp us direct.

Conclusion

Secure reliable carton erectors through verified manufacturers offering customization, global logistics, and comprehensive technical support tailored to your production needs.