3-year warranty | CE+OSAH certification | 10T-500T can be customized

In the fast-paced world of industrial waste management, vertical hydraulic balers stand as game-changing solutions for businesses seeking space efficiency, cost savings, and environmental compliance.

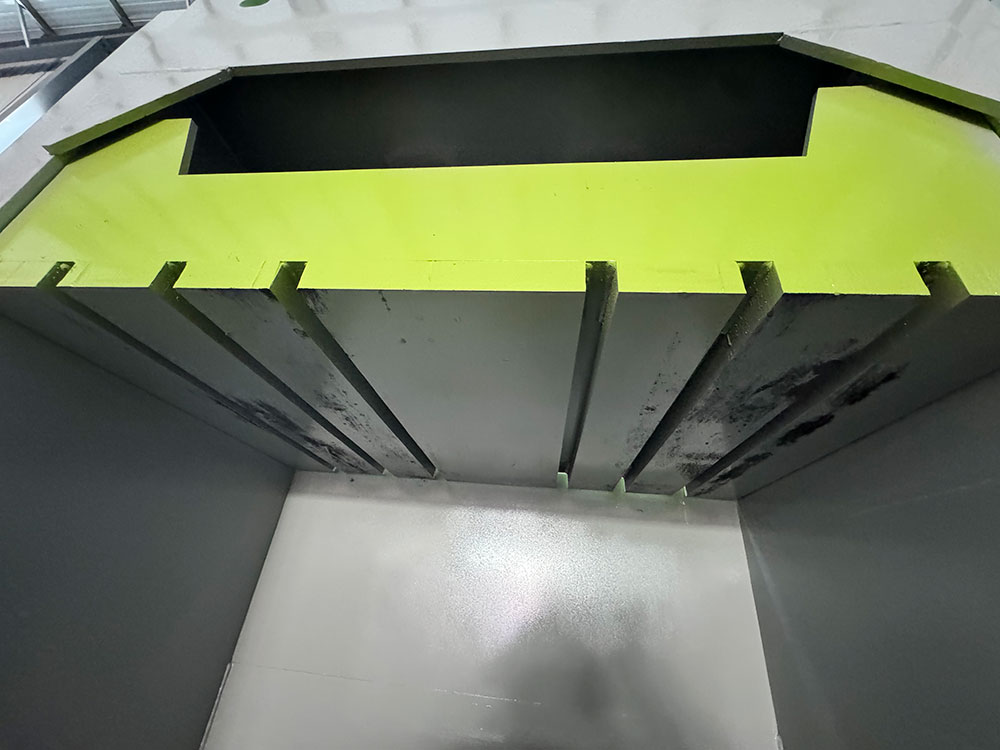

Frame Material

The whole machine is made of high-strength Q345B carbon steel (tensile strength ≥ 470MPa), the thickness of the column is up to 25mm, and the life of the box is over 200,000 cycles;

Sealing system

Germany Bosch quadruple-guided sealing cylinder + built-in piston chrome layer (thickness 0.05mm), hydraulic oil leakage rate <0.5mL/hour (industry standard 1.5mL);

Sealing system

Germany Bosch quadruple-guided sealing cylinder + built-in piston chrome layer (thickness 0.05mm), hydraulic oil leakage rate <0.5mL/hour (industry standard 1.5mL);

Dynamic pressurisation technology

The main pressure plate is equipped with a phased pressurisation module, supporting 50-300 tonnes of infinitely adjustable

PLC preset ‘paper/plastic’ modes, the system automatically matches the optimal pressure curve, and the compression density is increased by 25%;

I. 5 Competitive Advantages of Vertical Hydraulic Balers

1. Space-Saving Design for Compact Facilities

Vertical hydraulic balers are engineered for space-constrained environments, making them ideal for warehouses, retail stores, and small manufacturing plants. Unlike horizontal balers, their upright structure occupies minimal floor space (as little as 3.5㎡) while maximizing vertical clearance.

2. Energy Efficiency & Low Operational Costs

Equipped with 22kW low-power motors and automatic shut-off systems, vertical balers reduce energy consumption by up to 40% compared to traditional models. Advanced hydraulic circuits minimize oil leaks, ensuring long-term reliability.

Cost-Saving Stats:

Annual maintenance costs: <$800 (50% lower than industrial horizontal balers).

Lubrication-free components reduce downtime.

3. User-Friendly & Safe Operation

Designed for quick material switching and minimal training requirements, vertical balers feature:

One-touch control panels: Pre-set programs for plastics, cardboard, and textiles.

Safety enhancements: Emergency stop buttons, anti-rebound locks, and noise levels below 68dB (compliance with OSHA standards).

4. High-Quality Bale Output

Vertical balers produce denser, uniform bales (up to 500kg/m³) that optimize storage and transportation. Customizable pressure settings (50–120 tons) adapt to materials like:

Corrugated cardboard

PET bottles

Aluminum scraps

5. Eco-Friendly Waste Management

By compacting recyclables, vertical balers help businesses:

Reduce waste volume by 80–90%, lowering landfill costs.

Streamline recycling for carbon credit programs.

Meet sustainability certifications (e.g., ISO 14001).

II. Our Customer-Centric Services

1. Pre-Sales Consultation & Customization

Free Facility Assessment: Our engineers evaluate your space, power supply, and material types to recommend tailored solutions.

Custom Build Options: Modify door positions, add IoT sensors, or integrate conveyor belts.

2. Installation & Training

72-Hour Installation Guarantee: Licensed technicians deliver plug-and-play setup.

Onsite Training: 3-hour sessions covering operation, safety protocols, and basic troubleshooting.

3. After-Sales Support

24/7 Remote Diagnostics: Real-time monitoring via our BalerPro Connect platform.

Spare Parts Network: Next-day delivery for seals, blades, and hydraulic pumps.

Warranty: 3-year coverage on the main frame, 1 year on hydraulic systems.