Maximize Load Stability and Reduce Material Waste with Our Advanced Pallet Wrapping Machines

✅ Ultra-Intelligent Automation:

Unmanned operation slashes labor costs by 70%

3D vision system adapts to irregular load shapes for optimal wrapping paths

Seamless integration with AGV/conveyor systems

✅ Industry-Leading Efficiency:

⚡ Wraps 120+ pallets/hour with 24/7 operation

Dual robotic arms double throughput

✅ Eco-Friendly Design:

Pre-stretch technology cuts film use by 50%

Adaptive tension algorithms ensure zero product damage

| Feature | Traditional Wrappers | Our Robotic Wrapper |

|---|---|---|

| Load Adaptability | Standard shapes only | ✅ Any shape (cylindrical, irregular) |

| Film Savings | 10~20% | ✅ Up to 50% |

| Footprint | 15㎡ | ✅ 8㎡ (40% smaller) |

| Annual Maintenance | $2,000+ | ✅ <$800 |

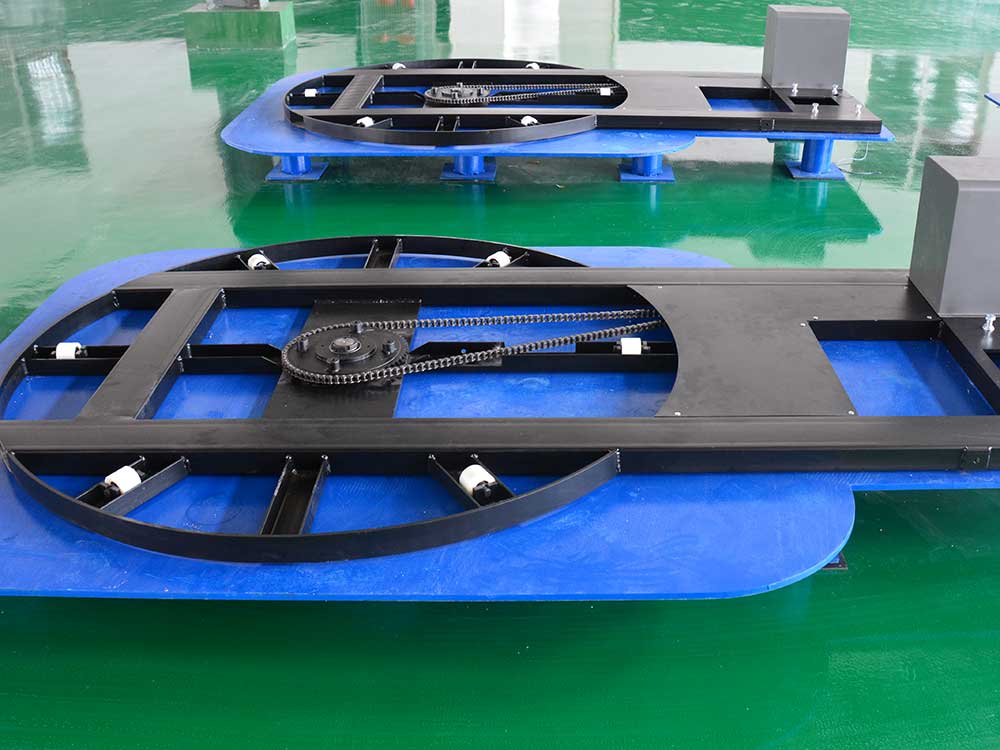

1. What is a Robot Pallet Wrapping Machine?

A robot pallet wrapping machine is an advanced packaging system that automates the process of securing palletized loads with stretch film. Unlike traditional wrappers, it uses robotic arms guided by AI and 3D vision to adapt wrapping patterns to uneven loads, improving consistency and reducing film waste.

2. How Does It Work Compared to Manual or Semi-Automatic Wrappers?

Manual wrapping: Workers apply film by hand, prone to inconsistency and fatigue.

Semi-automatic: Load spins while film is dispensed—limited to uniform shapes.

Robotic wrapper:

Scans pallet dimensions with 3D sensors.

Calculates optimal film tension and rotation path.

Delivers 360° precision wrapping at 120+ pallets/hour.

3. What Industries Benefit Most from Robotic Pallet Wrappers?

Food & Beverage: Hygienic wrapping for cold storage (-30°C capability).

Automotive: Zero-vibration wrapping for fragile auto parts.

E-commerce: Handles 3,000+ daily pallets with mixed SKUs.

Pharmaceuticals: Compliant with GMP standards.

4. How Much Film Can It Save?

Robotic wrappers use pre-stretch technology and adaptive algorithms to reduce film usage by up to 50% versus manual methods. For example:

Manual: 200g film per pallet → Robotic: 100g/pallet.

Savings: $12,000/year for 500 daily pallets.

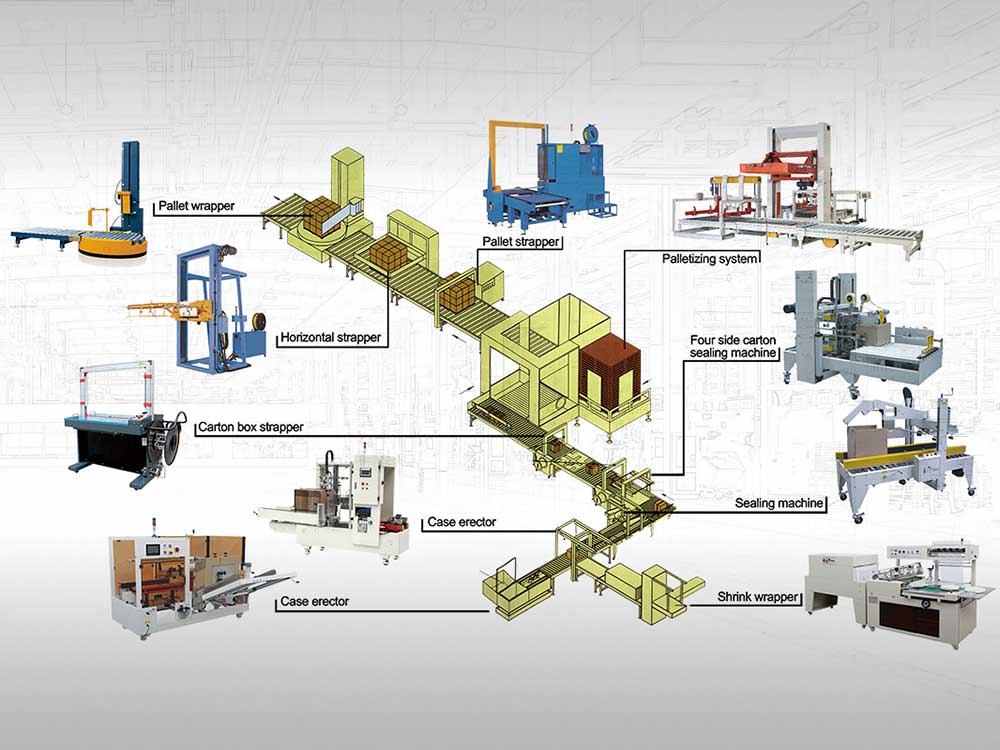

5. Is It Compatible with Existing Warehouse Systems?

Yes! Modern robotic wrappers integrate seamlessly with:

AGVs (Automated Guided Vehicles).

Conveyor belts.

ERP/MES software via IoT connectivity.

No facility upgrades required.

6. What’s the Payback Period for the Investment?

Most businesses recover costs in 6-12 months through:

70% reduced labor costs (e.g., $150k → $40k/year).

50% lower film expenses.

Fewer product damages (up to 2% → 0.1%).

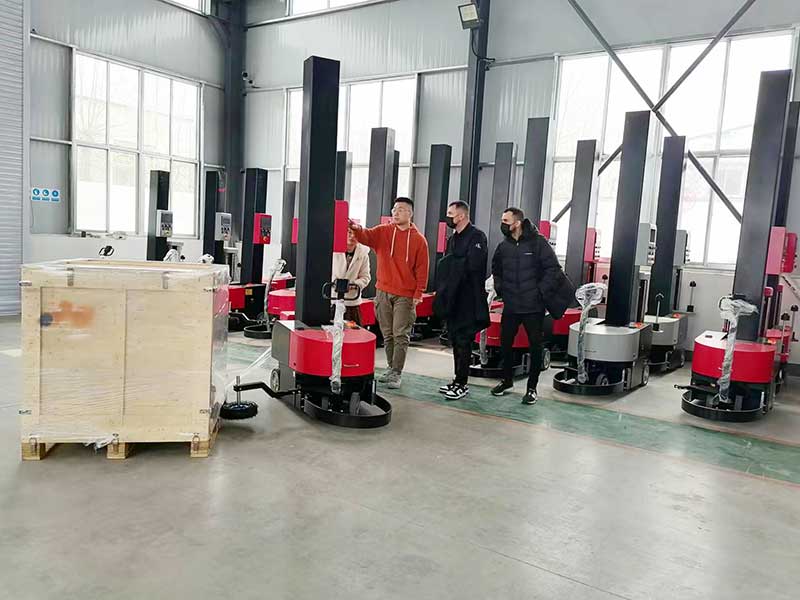

7. How Long Does Installation Take?

Deployment typically takes 2-3 days, including:

2-hour hardware setup.

Software calibration for load profiles.

Staff training via intuitive HMI panels.

8. Can It Handle Odd-Shaped or Fragile Loads?

Absolutely! Machine vision and adaptive algorithms enable:

Wrapping for cylinders, drums, and mixed-load pallets.

Gentle tension control for glass or electronics.

Custom patterns for unstable loads.

(Keywords: robotic wrapper for irregular loads)

9. What Maintenance Is Required?

Daily: Clean sensors and film carriage.

Monthly: Lubricate robotic joints.

Annual: Software updates (often included in warranties).

Predictive maintenance alerts via IoT prevent downtime.

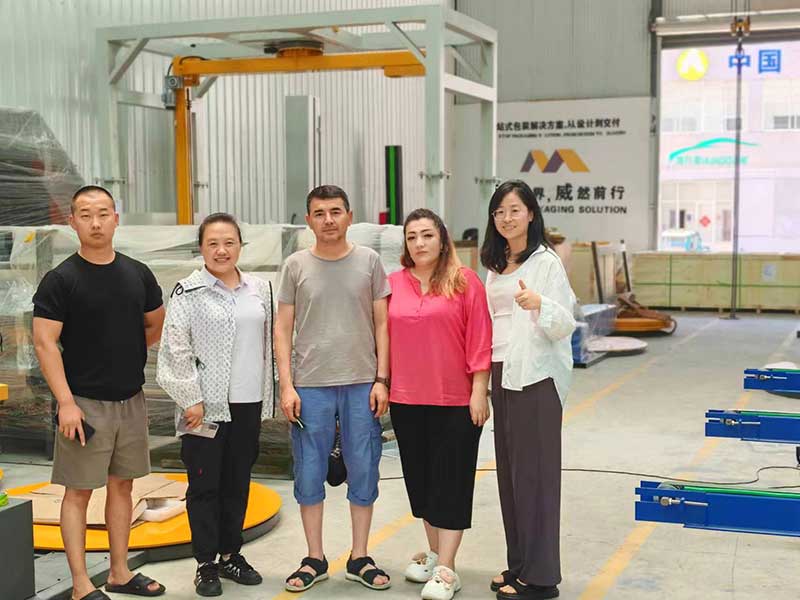

10. How to Choose the Right Supplier?

Ask these questions:

Do you offer explosion-proof models for chemical plants?

Can the machine handle 1,500kg+ loads?

Is remote technical support available 24/7?

What certifications do you have (CE, UL, ISO)?

Why Automate Your Pallet Wrapping?

Robotic pallet wrappers eliminate labor bottlenecks, cut material waste, and future-proof packaging lines. With ROI under 12 months for most facilities, they’re a proven upgrade for industries scaling e-commerce, cold chain, or heavy manufacturing.