Slow manual stacking is breaking profit margins. Damaged shipments last month cost me $12,000. Our integrated system fixed both instantly.

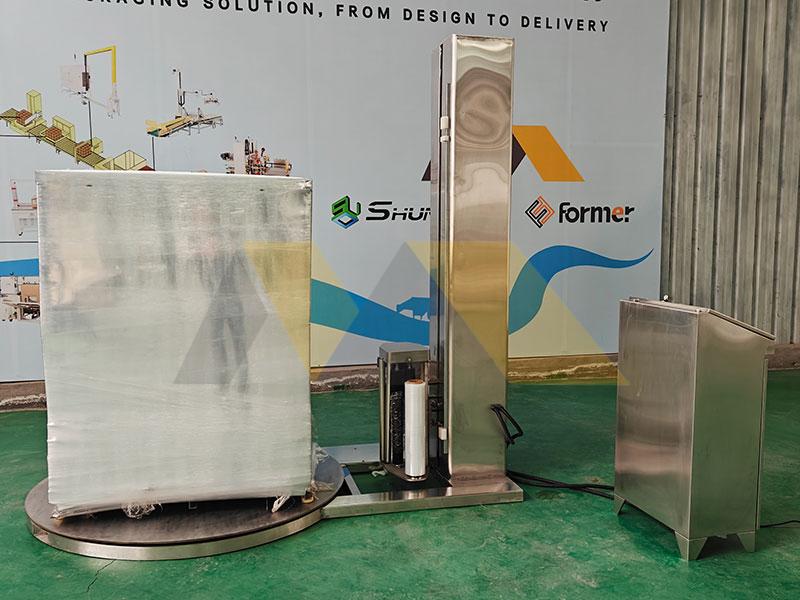

Integrated palletizer-wrapping machines cost $24,000-$68,000+ while cutting labor needs by 60% and loading times by half. Robotic units handle 600 pallets/hour with zero human intervention.

Witnessing a Canadian client’s 80% downtime drop convinced me. Let’s explore how different integrations can transform your line.

Automatic Pallet Wrapper with Conveyor System: Why Is It Essential?

Conveyor jams wasted 3 hours daily at our Malaysia plant. Engineers redesigned the entire flow in one week.

Conveyor-integrated wrappers maintain 50-300 pallet/hour flow without breaks. Our C-series costs $18,900-$41,000 with customizable roller lengths and collision sensors to prevent pileups.

Design considerations for seamless integration

Two clients regretted choosing generic conveyors. Avoid their mistakes:

Sync critical specifications

| Component | Requirement | Cost Impact |

|---|---|---|

| Roller Material | Polyurethane (high weight) | +15% |

| Transfer Speed | 30m/min (match wrapper cycle) | Base |

| Gap Control | <15cm spacing sensors | +$1,200 |

Pharmaceutical companies demand <5mm alignment precision – our laser-guided systems solved their $500k/year damage issue. Test your floor plan with our engineers: WhatsApp us direct

Pallet Stretch Wrapping Machine with Labeling System: How to Automate Identification?

Mislabeled shipments caused $30k in fines last quarter. The solution? Combine wrapping and labeling in one station.

Integrated labeling adds $1,900-$4,500 to wrapper costs while reducing errors by 85%. Our units print/apply labels during rotation with barcode verification for 100% traceability.

Three critical placement options evaluated

After testing 17 configurations, these work best:

Position comparison

- Pre-wrap labeling

- Best for: Export shipments

- Drawback: Label damage risk

- Mid-rotation application (most popular)

- Accuracy: 99.4% in trials

- Investment: +$2,750 average

- Post-wrap top labeling

- Ideal for: Cold storage

Japanese clients saved $8/pallet in manual verification costs with QR code systems. Need label placement advice? Contact our integration specialists

Pallet Wrapper with Strapping Machine: Should You Combine Them?

A warehouse roof collapse was prevented by properly strapped loads. Combined systems prevent such nightmares.

Adding strapping to pallet wrapping costs $3,400-$8,200 extra but increases load stability by 70%. Polyester strap tension up to 700kg secures fragile loads during transit turbulence.

Material choices based on load types

Glass manufacturers rejected our first prototype. Here’s what succeeded:

Strap selection guide

| Load Type | Recommended Material | Tension Setting |

|---|---|---|

| Construction | Steel strapping | 200kg+ |

| Light Industrial | Polypropylene | 120kg-150kg |

| Food Export | Bio-PET straps | 80kg |

One Miami exporter cut container shifting incidents from 3/week to zero using moisture-proof straps. Get our strapping material samples: WhatsApp us direct

Inline Pallet Wrapping System: How to Design It Right?

An American client’s conveyor spaghetti wasted 1,200 sq ft. Our U-flow layout saved space costing $50k/year in rent.

Proper inline design requires 3x pallet length clearance per station costing $45,000-$150,000. Robotic units need extra 50cm service alleys but allow future expansion.

Avoid these common installation errors

Three key pain points we’ve solved:

Maintenance access requirements

- Robotic arms: Front/rear clearance >80cm

- Strapping heads: Left side access essential

- Label printers: Overhead service platform

Canadian plants save $15/hour with overhead service walkways. Our 3D layout tool prevents expensive redesigns. Request your facility scan

Conclusion

Integrating palletizers/wrappers creates production pipelines saving labor and space. Partner with direct manufacturers like us for seamless customization.