Maximize Load Stability and Reduce Material Waste with Our Advanced Pallet Wrapping Machines

✅ Industry-Leading Durability: Built to withstand high-volume operations with premium-grade components.

✅ Smart Automation: Precision sensors and programmable settings for consistent, hands-free wrapping.

✅ Cost Savings: Reduce stretch film usage by up to 30% with optimized tension control.

✅ Fast ROI: Boost productivity by 50% and minimize labor costs.

✅ 24/7 Support: Expert technical assistance and warranty coverage.

🔹 Adjustable Wrapping Modes: Customizable programs for fragile, heavy, or irregular loads (e.g., cylindrical items, unstable stacks).

🔹 Turbo-Speed Wrapping: Achieve up to 60 pallets per hour with dual-motor drive systems.

🔹 Energy-Efficient Operation: Eco-mode reduces power consumption by 25% during downtime.

🔹 Film Clamp & Cut Technology: Automatic film securing and cutting for seamless transitions.

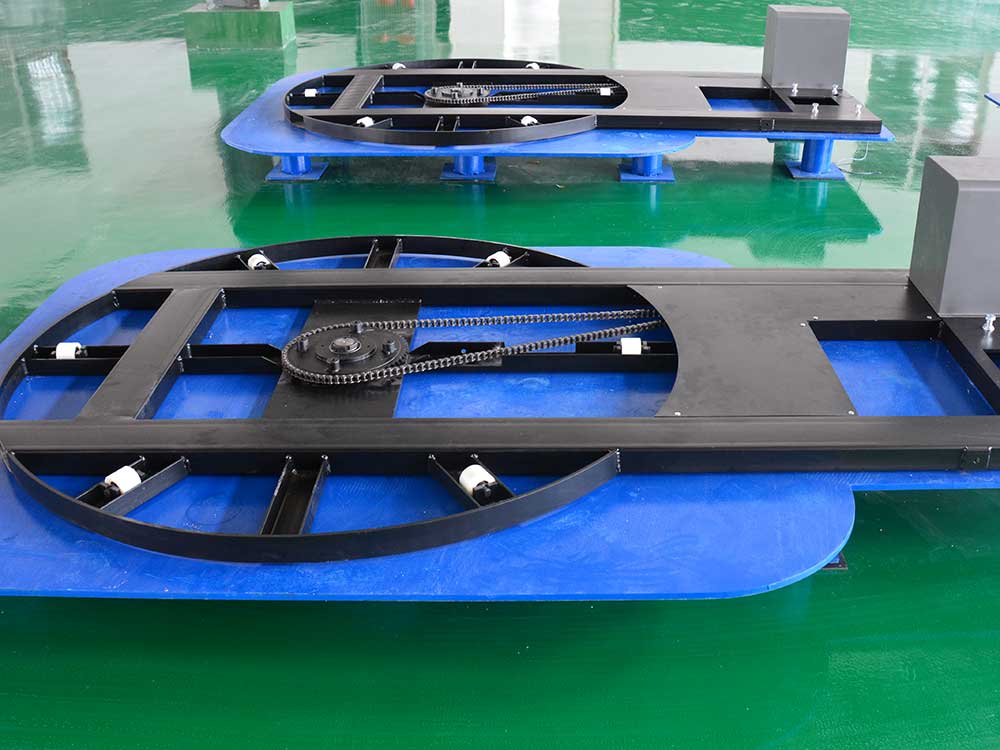

🔹 360° Rotational Turntable: Heavy-duty steel turntable supports loads up to 3,000 lbs.

🔹 Smart Tension Control: Dynamically adjusts film tension to prevent tearing or overstretching.

🔹 Remote Diagnostics: IoT-enabled machines allow real-time troubleshooting via mobile app.

🔹 Multi-Layer Wrapping: Optional top-sheet cover for humidity-sensitive shipments.

🔹 Modular Design: Easily upgradeable with add-ons like weighing scales or label printers.

🔹 Low-Noise Operation: Under 70 dB for worker-friendly environments.

🔹 Load Height Detection: Auto-adjusts wrap cycles based on pallet height (10-100 inches).

🔹 Compliance Certified: Meets OSHA, CE, and ANSI safety standards.

Q1: What is a Pallet Wrapping Machine, and How Does It Work?

A pallet wrapping machine (or stretch wrapper) secures goods on pallets by tightly binding them with stretch film.

It rotates the pallet on a turntable while dispensing film vertically or horizontally. Modern machines use programmable settings to adjust tension, speed, and layers for optimal load stability.

Q2: Why Invest in an Automatic Pallet Wrapper Instead of Manual Wrapping?

Automatic wrappers save labor costs, reduce film waste by 20–40%, and ensure consistent tension for damage-free shipping.

They wrap 50+ pallets per hour versus 10–15 manually, ideal for warehouses with high-volume logistics.

Q3: What Types of Pallet Wrapping Machines Are Available?

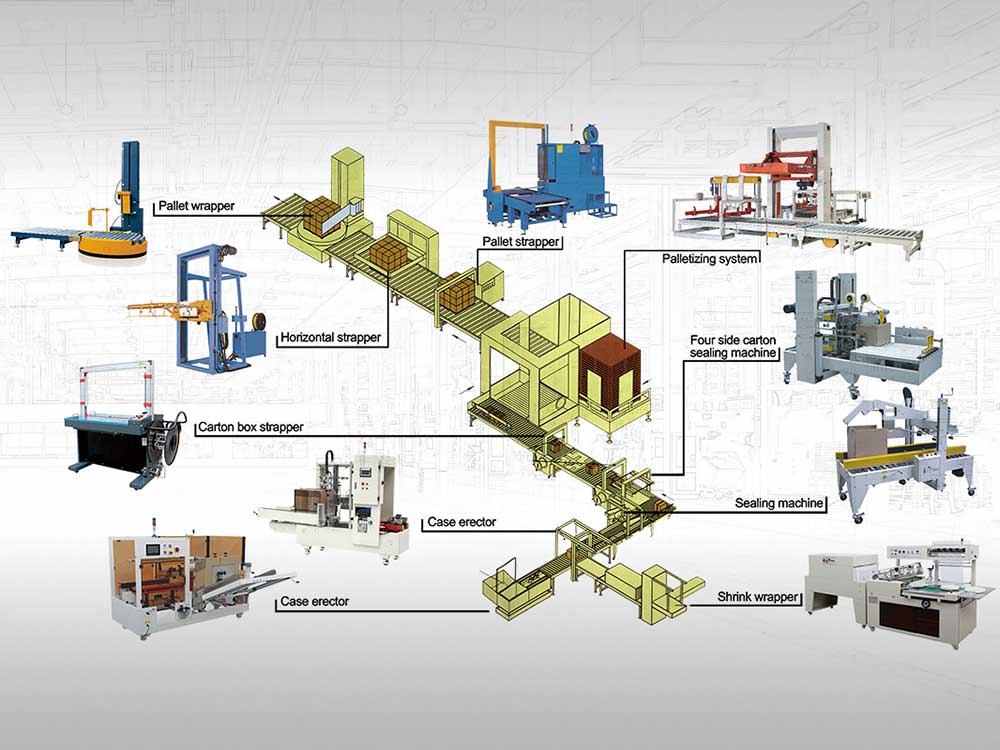

Semi-Automatic: Operator places the pallet; machine handles rotation and wrapping.

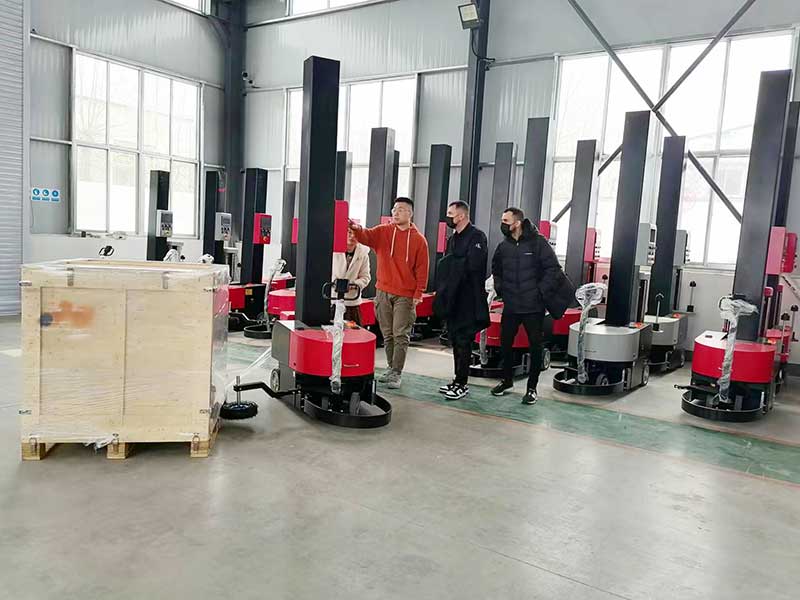

Fully Automatic: Integrated conveyor systems load, wrap, and discharge pallets autonomously.

Robotic Wrappers: Customizable arms for irregularly shaped loads.

Mobile Wrappers: Portable units for multi-zone warehouse use.

Q4: How to Choose the Right Pallet Wrapper for My Business?

Consider

Throughput: Volume of pallets per hour.

Load Weight/Size: Machines support 1,500–6,000 lbs; turntable diameter up to 80″.

Film Type: Compatibility with pre-stretch or standard film.

Special Needs: Humidity resistance, outdoor use, or IoT integration.

Q5: Can Pallet Wrappers Handle Fragile or Irregularly Shaped Loads?

Yes! Advanced models feature:

Variable Tension Control: Adjusts film tightness for delicate items.

Pattern Customization: Extra layers around edges or gaps.

Top-Sheet Dispensers: Add protective covers for stability.

Q6: How Much Does a Pallet Wrapping Machine Cost?

Semi-automatic: $5,000–$15,000.

Fully automatic: $20,000–$60,000.

Robotic systems: $70,000+.

Tip: Leasing or refurbished options can reduce upfront costs.

Q7: What Maintenance Do Pallet Wrapping Machines Require?

– Daily: Clean sensors and remove film debris.

– Monthly: Lubricate chains and inspect motors.

– Annual: Professional calibration for tension accuracy.

Most machines include self-diagnostic tools to simplify upkeep.

Q8: Are Pallet Wrappers Safe to Use?

Modern wrappers comply with OSHA/ANSI standards and include:

– Emergency stop buttons.

– Anti-slip turntables.

– Safety curtains to prevent operator interference.

Q9: How to Reduce Stretch Film Waste with a Pallet Wrapper?

– Use **pre-stretch film** (reduces usage by 30–50%).

– Enable **eco-mode** to optimize tension.

– Train staff to avoid over-layering.

Q10: Where Can I Get a Reliable Pallet Wrapping Machine?

Trust suppliers offering:

– Free demos or ROI calculators.

– Warranties (3+ years on critical parts).

– On-site training and 24/7 support.

Still Have Questions?

📞 Call our packaging experts at +86 13505379893

📧 Email [email protected]

https://mywaymachinery.com/contact/