Protect Your Cargo 3x Faster with Industrial-Grade Wrapping Technology

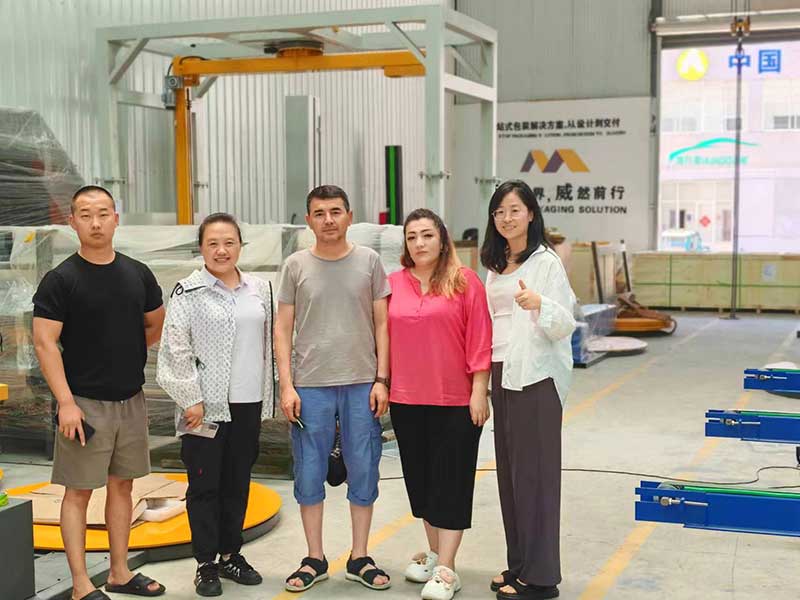

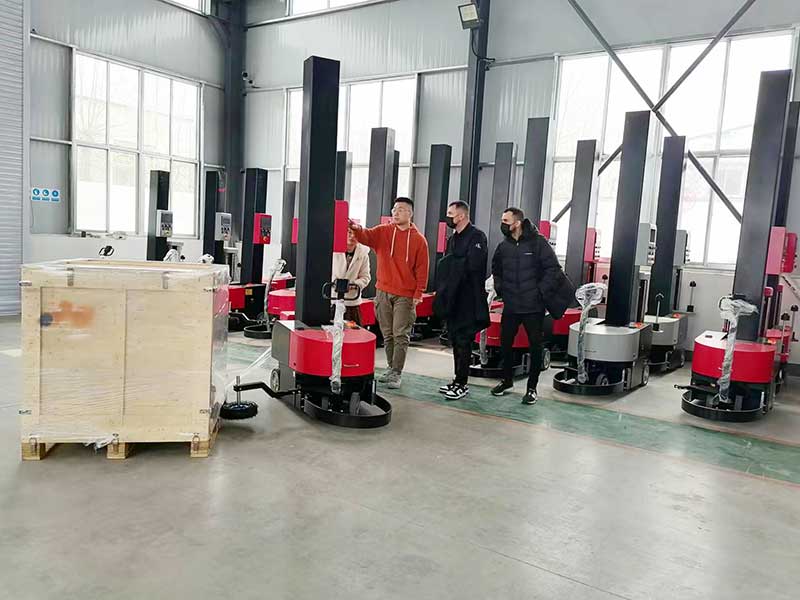

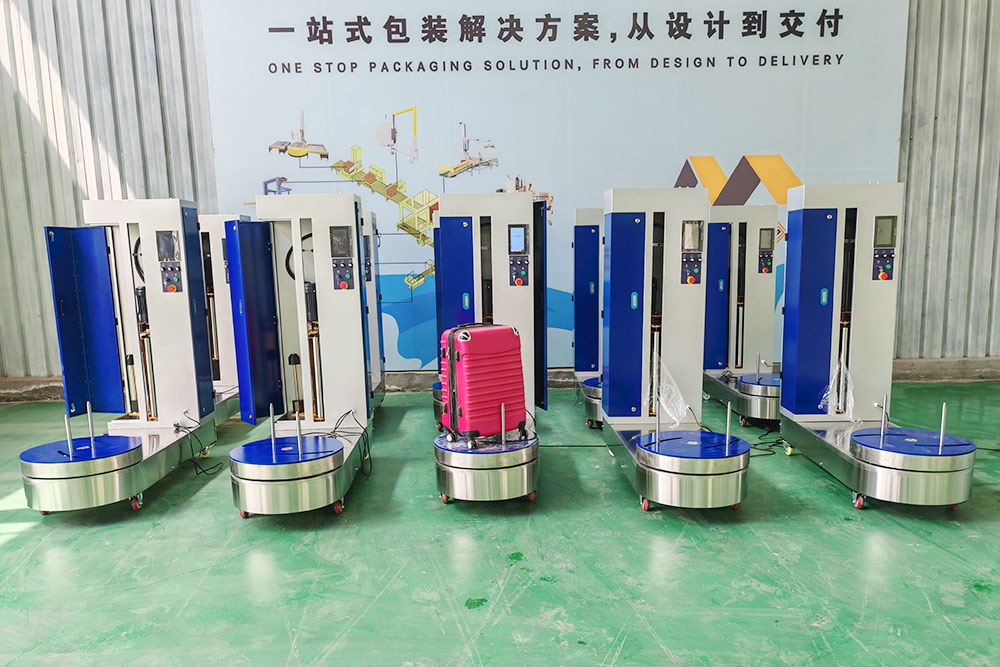

t Myway, we engineer excellence in industrial packaging. As a leading Chinese manufacturer specializing in stretch wrapping machines and fully customizable packaging lines, we power businesses across 50+ countries with reliable, and cost-effective solutions tailored to your unique needs.

🔝 Industrial-Grade Durability Built for 24/7 Operations

✅ TÜV-Certified German Components

Our machines integrate Siemens motors and Schneider Electric control systems, engineered to deliver 50,000+ continuous cycles with ≤0.1% downtime rate – ideal for high-traffic airports and logistics hubs.

✅ Military-Grade Corrosion Resistance

The patented multi-layer composite body adopts 304 stainless steel substrate + nano-ceramic coating technology, passes 96hr salt spray test, and perfectly adapts to the extreme humid environment of the Middle East/Southeast Asia.

✅ Intelligent Fault Warning System

Equipped with vibration sensor and temperature monitoring module, it can warn potential problems 72 hours in advance and reduce 87% of sudden downtime losses.

⏱️Industry-leading winding efficiency – 2.8 times faster than traditional models

🔥 High-speed mode: Innovative dual-motor drive structure achieves ultra-fast winding speed of 45sec/piece (industry average 72sec), and the daily production capacity can reach up to 2,000 pieces.

🔥 Intelligent tension optimization

Real-time calculation of cargo size through laser scanning, automatic adjustment of film tension to the golden range of 0.25-0.5N/mm², reducing film waste by 32%.

🔥 Prefabricated solution library

Pre-installed 50+ airport/customs/express-specific winding solutions, one-click switching of international logistics standard parameters such as DHL/Fedex.

🌍Global compliance certification — worry-free entry into international hub ports

⚡ Dual certification guarantee: All models are 100% certified by CE Machinery Directive (EN-13478) and IATA aviation safety verification before leaving the factory.

⚡ Environmental compliance upgrade

Using UL-certified silent motors (≤58dB) and RoHS-compatible materials to meet EU EPR and California Proposition 65 requirements.

⚡ Localized service network

With spare parts centers in Rotterdam/Dubai/Los Angeles, providing 72hr global emergency response, including Chinese/English/Arabic technical support.

📈Smart IoT Ecosystem — Data-enabled Warehouse Management

🤖 Cloud Platform Docking

Supports direct connection with ERP systems such as SAP and Oracle, and real-time tracking of equipment OEE (overall equipment efficiency) and film consumption data.

🤖 Preventive Maintenance Reminder

Built-in AI algorithm analyzes 5,000+ operating parameters, proactively pushes bearing lubrication/tool replacement reminders, and extends the life of key components by 3-5 years.

🤖 Multi-level Permission Management

Through NFC cards, three-level permission control for operators/supervisors/maintenance engineers is achieved, in compliance with ISO 27001 information security standards.

💰Cost Control Revolution — ROI Visible in 18 Months

💡 Modular Design

The core unit adopts a quick-disassembly architecture, which shortens maintenance time by 65% and reduces maintenance costs to 1/3 of competitors.

💡 Energy Optimization Mode

Equipped with EcoSmart dynamic power adjustment technology, it reduces power consumption by 41% compared to traditional models, and saves up to $8,200+ in electricity bills annually.

💡 Film Adaptation System

Fully compatible with LDPE/LLDPE/PVC and other materials (thickness 15-50μm), customers can freely purchase local raw materials to reduce costs.

🚀Customized on demand – fit for special operating scenarios

✨ Full size coverage

Support customized development to handle special needs from 500mm small express boxes to 2.4m ultra-large musical instrument boxes.

✨ Special machine model solution

Explosion-proof version (suitable for chemical logistics)

Constant temperature version (-30°C to 50°C extreme environment)

AGV automatic docking version (special for smart warehouses)

✨ Brand joint development

Provide Private Label service, support customized equipment appearance color, operation interface language, and corporate logo laser engraving.