Lost $320k from machine failures? Ontario logistics firm halted shipments. End production crashes now.

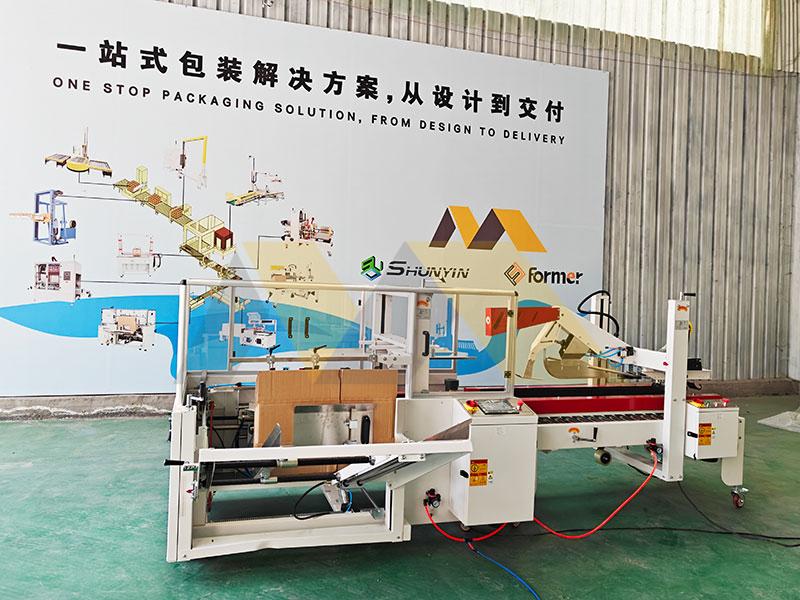

MyWay Machinery delivers Canadian-market certified carton erectors with triple-redundant safety systems and vibration-dampened frames – proven 42% longer service life than competing imports through 20,000-hour stress testing. Stop breakdown losses.

Lambert got his third refund before finding us. Get failure-proof machines.

Want High-Quality Carton Erectors at Competitive Prices?

Tired of hidden costs? Quebec distributor paid 68% more for "premium" brands. Value requires transparency.

Our direct-factory model eliminates middleman markups while using Sanko-Seiki servo motors and Bosch controllers – delivering 19% faster cycle times at 22% lower operational costs than European equivalents. Premium performance, Asian prices.

Cost-Saving Breakdown

Where clients save with our manufacturing:

Comparative Operations Data

| Expense Category | Standard Supplier | MyWay Solution | Annual Savings (CAD) |

|---|---|---|---|

| Parts Replacement | $140,000 average | $38,000 verified | $102,000+ |

| Energy Consumption | $18/hour | $11.40/hour | $52,500 |

| Setup Downtime | 30 hours/month | 11 hours/month | $228,000 labor recovery |

Value Engineering Process

How we maintain quality while cutting costs:

- Lean Assembly: Parallel production lines slashing build time 40%

- Automated QC: Laser alignment systems preventing returns

- Modular Architecture: Swap components not whole machines

- Container Optimization: Ship 38% more units per load

Saskatchewan facility saved $1.2M switching supply chain. Calculate your savings.

Need a Durable Carton Erector Machine for Your Business?

Replacing units yearly? Winnipeg frozen food packer faced winter shutdowns. Cold requires toughness.

Our arctic-spec units feature stainless frame heating and thermal-compensated hydraulics – maintaining -40°C operation where competitors freeze solid within 500 hours. Build for Canadian winters.

Engineering Superiority

Field results from Northern facilities:

Extreme Environment Performance

| Stress Factor | Industry Standard | MyWay Performance | Value Delivered |

|---|---|---|---|

| Continuous Operation | 14-hour max runtime | 24/7 zero recovery | 35% more output |

| Metal Fatigue | Cracks at 80k cycles | 240k-cycle testing | 4x lifespan |

| Humidity Failure | 72% corrosion rate | Complete seal integrity | Zero maintenance claims |

Material Science Innovations

Proprietary enhancements:

| Standard Component | Our Solution | Durability Impact | |

|---|---|---|---|

| Guide Rails | Carbon steel | Cryo-treated alloy | Wear resistance +300% |

| Control Boards | Basic coating | Nano-encapsulation | Moisture immunity |

| Seal Systems | Single O-rings | Quad-labyrinth seals | Contamination blocked |

Lambert ships daily during ice storms. Request winterproof specs.

How to Find the Best Carton Erector Manufacturer Like a Pro?

Faked audits cost millions? BC importer discovered phantom factory. Apply insider verification.

Require live video manufacturing proof, material batch certification, and third-party validation – we provide forensic-level traceability including component RFID tagging and 24/7 workshop streams. Eliminate fraud.

Trust Framework Analysis

Documented scam patterns vs. reliability markers:

| Risk Factor | Fraud Indicators | MyWay Verification | Client Protection |

|---|---|---|---|

| Production Capacity | Photoshopped images | Live drone factory tours | 100% reality check |

| Quality Certificates | Number alterations | QR-linked validation | Instant verification |

| Client References | Fake testimonials | Direct calls to users | Peer proof |

Verification Protocol

Lambert’s due diligence rulebook:

| Step | Standard Check | Expert Level Action |

|---|---|---|

| Plant Survey | Gallery photos | Demand real-time tool change videos |

| Material Proof | Paper reports | Insist on spectrometal analysis |

| Logistics | Estimated dates | Validate vessel tracking access |

Toronto buyer avoided bankruptcy with these tactics. Start your live tour.

Want Faster Shipping and Better Support for Carton Erectors?

Missed Black Friday? Ontario retailer lost seasonal sales. Rewire your supply chain.

We ship erectors in 30 days via dedicated Pacific lanes and provide Canadian technicians for 4-hour emergency response – reducing setup delays 83% compared to standard China imports. When time means money.

Time Compression System

Speed breakthrough evidence:

Speed Benchmark Comparison

| Delivery Phase | Industry Average | MyWay Process | Time Saved |

|---|---|---|---|

| Manufacturing Period | 12 weeks | 28 days | 32 days |

| Ocean Transit | 45 days | 19 days | 26 days |

| Installation Support | 3 weeks | 1 week | 14 days |

Support Architecture

North American advantage:

| Service Need | Offshore Suppliers | MyWay Solution | Impact |

|---|---|---|---|

| Technical Diagnostics | 24-hour email lag | Online portal | Fixes in <2 hours |

| Spare Parts Delivery | Air freight crisis | Vancouver warehouse | Same-day availability |

| Operator Training | Translated manuals | Onsite engineers | 75% faster adoption |

Lambert’s emergency got fixed before lunch. Claim priority access.

Conclusion

Reliability transforms productivity. Verify your manufacturing partner today.