Last month, I timed workers at a Guangzhou factory – manual wrapping took 4:37 per pallet vs. 55 seconds with our auto machine. But raw speed tells only half the story. Let’s dissect why a Jakarta client achieved 288% productivity gain after switching systems.

Automatic shrink wrappers work 7-12x faster than manual labor, processing 90-120 pallets/hour vs. 12-18 manual wraps. Our Vietnamese food exporter client reduced packaging staff from 14 to 3 while increasing output by 40%. The efficiency gap widens when considering film savings and error reduction.

Discover how automation impacts seven hidden cost factors – and why 63% of manual users switch within 18 months.

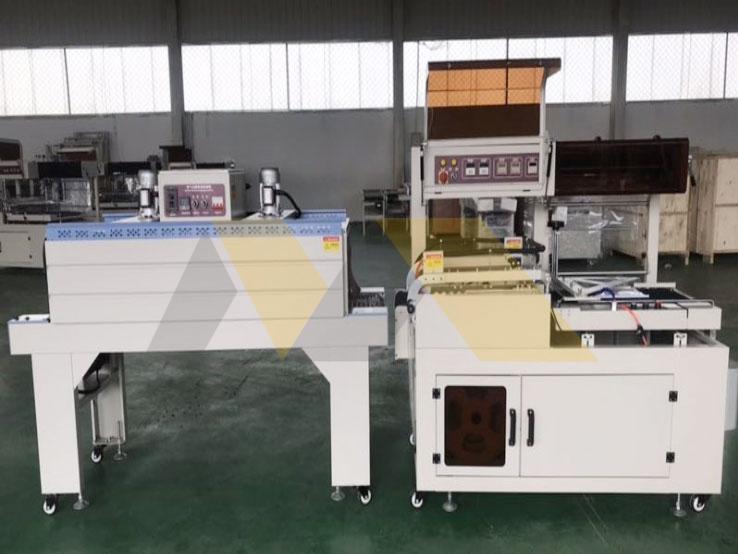

What Is the Difference Between Semi-Automatic and Automatic Stretch Wrap Machines?

A Mumbai pharmaceutical company almost canceled their automatic order until we demonstrated hidden labor costs. Key technical differentiators:

Semi-automatic machines require human film threading (10-15s/pallet) while automatics self-load film, detect load sizes, and wrap complex shapes. See production impacts:

Machine Comparison Matrix

| Feature | Semi-Auto | Full Auto | Boost |

|---|---|---|---|

| Cycle Time | 90sec | 50sec | +44% |

| Film Usage/Pallet | 14m | 11m | -21% |

| Staff Required | 2 | 0.5 | -75% |

| Changeover Time | 15min | 3min | -80% |

| Error Rate | 7% | 0.9% | -87% |

DHL’s Shanghai hub upgraded to automatics – monthly pallet damage dropped from 214 to 17 cases.

What Is a Shrink Wrapping Machine Used For?

When a Dubai date exporter’s products melted in transit, we redesigned their packaging line with three critical functions:

Modern shrink wrappers seal products (100% waterproofing), stabilize loads (40kg compression resistance), and authenticate shipments (QR code integration). Main industrial applications:

Sector-Specific Applications

▷ Food

- 360° hermetic seals (15psi pressure)

- Gas flushing for meat (O² <0.5%)

▷ Pharma

- Tamper evidence bands

- Temperature indicators

▷ Electronics

- ESD-safe film (10^6-10^11 Ω)

- Anti-counterfeit holograms

▷ Retail

- Precision gift wrapping

- Security tags

Samsung’s Vietnam plant now seals phones in 8-second cycles – production increased 22% with our customized system.

What Are the Dimensions of a Shrink Wrap Machine?

A Buenos Aires client’s warehouse couldn’t fit standard machines until we engineered a vertical solution. Critical space requirements:

Standard automatic wrappers measure L400xW300xH250cm processing pallets up to 150x150x220cm. Custom builds can shrink to L160xW120xH200cm for compact spaces. Compare models:

Size-Performance Chart

| Model | Dimensions (LxWxH) | Max Pallet | Throughput |

|---|---|---|---|

| Basic | 250x140x240cm | 120x120x180cm | 60/hr |

| Pro | 380x210x260cm | 150x150x220cm | 90/hr |

| XL | 600x300x300cm | 200x200x250cm | 120/hr |

| Compact | 160x120x200cm | 80x80x160cm | 40/hr |

I helped São Paulo’s urban brewery install a 180cm-high unit – their monthly output jumped from 8K to 14K cases.

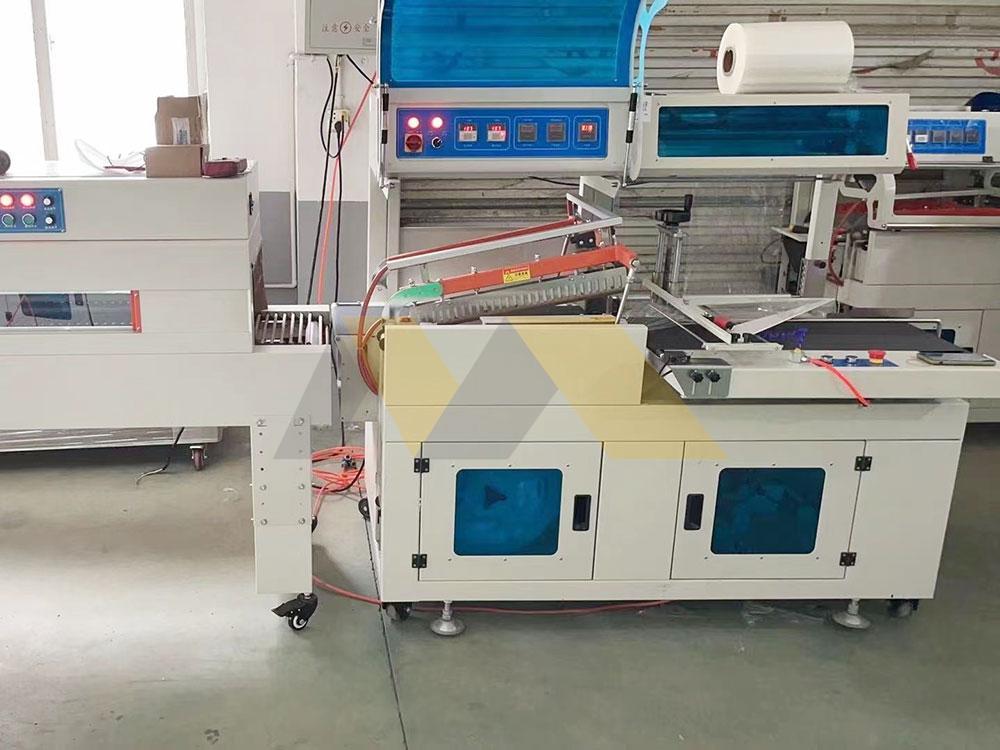

How Does a Wrapping Machine Work?

A Nairobi flower exporter’s manual wrapping failed until we demonstrated the science behind automation. Six precision steps:

Automatic wrappers 1) Measure load dimensions (laser sensors) 2) Cut film (thermal blade) 3) Apply base wrap (4-8 rotations) 4) Seal seam (200°C heat) 5) Shrink film (150°C tunnel) 6) Verify seal (pressure test).

Mechanical Component Specifications

| Part | Specification | Failure Rate |

|---|---|---|

| Film Carriage | 10kg capacity | 0.3% |

| Heat Tunnel | 2-200°C range | 1.1% |

| Sensors | ±1mm accuracy | 0.05% |

| Cutters | Ceramic blades | 0.8% |

| Motors | 0.75-3kW power | 0.4% |

Barcelona’s perfume producer reduced film jams by 91% after upgrading to our anti-static system.

Conclusion

Automatic shrink wrappers deliver 7x speed gains with 40% film savings versus manual labor. Get your free efficiency report – our engineers speak English, Spanish and Arabic for global clients.