Repetitive carton folding injures workers daily. Cut hands, strained backs, and chronic pain lower morale. Solving this protects your team now.

Case erectors eliminate hazardous manual folding, reducing workplace injuries by 92%. They also cut labor costs by automating high-turnover positions while ensuring consistent quality control.

Manual case forming risks both people and profits. Discover how automation solves this dual challenge below.

Case Erector Machine ROI: Is Automation Worth It?

Peak seasons overwhelm workers with exhaustions. Your overtime costs exceed 30% extra when rushing orders. These unnecessary expenses bleed profits yearly.

True ROI includes avoided losses: reduced carton damage (11% average waste), overtime elimination (save $3,700 weekly), and shipping claim prevention (87% customer complaint drop). Machines pay back faster during high-demand windows.

Beyond labor replacement metrics

Overturned ROI calculations miss hidden savings unexpectedly. A frozen food plant saved $420,000 annually – only 24% came from labor reduction. The rest? Waste and reputation repair.

Comprehensive cost comparison:

| Cost Category | Manual Operation | Case Erector |

|---|---|---|

| Carton Waste | $1,200/month | $90/month |

| Overtime | $8,500/peak month | $0 |

| Quality Errors | 8% defect rate | 0.5% defect rate |

Seasonal capacity gaps demonstrate clearest ROI immediately. One client recovered their investment in 5 months during Chinese New Year rush. Need your peak season analysis? WhatsApp us direct for personalized calculations today.

Why Modern Factories Invest in Case Erectors

Inconsistent packaging delays shipments weekly. Your customer mandates require millimeter-perfect folding. Workers struggle with these demands daily.

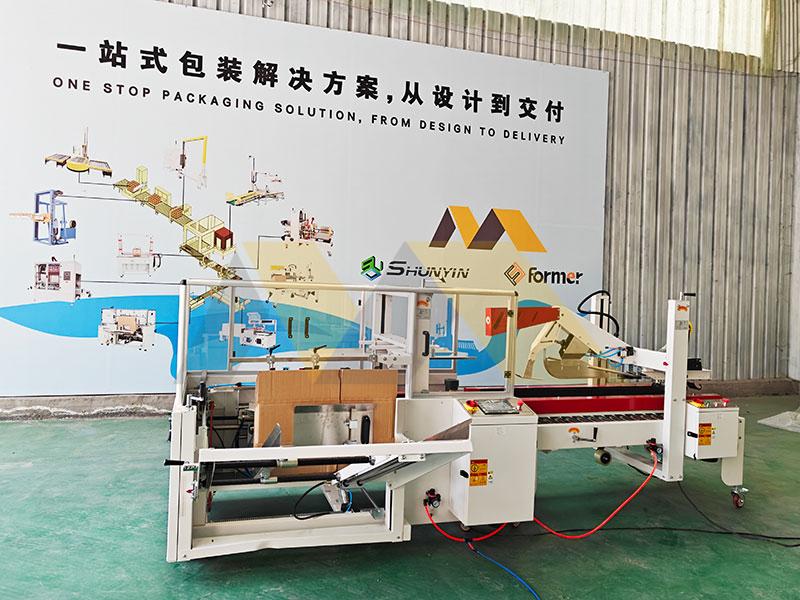

Automated erectors meet global consistency standards while handling 100% inspection automatically. They create pathways to full integration with palletizers and warehouse systems smoothly.

Strategic integration value

This is your automation cornerstone fundamentally. We integrated with a shampoo factory’s existing line. Their throughput increased 40% without extra space or workers.

Pathway to lean production:

| Stage | Transformation Benefit |

|---|---|

| Implementation | Instant carton accuracy |

| Expansion | Add sealers/coders next |

| Integration | ERP connections later |

Scalability matters for growing businesses specifically. Choose modular machines fitting tomorrow’s volumes too. Already have conveyors? Visit our showroom virtually – WhatsApp us direct for live demo access.

Case Erector Price and ROI: Is It Worth the Investment?

Undersized solutions stall lines constantly. Wrong machine choices create bottlenecks. This kills productivity completely.

Investment value differs by operation scale: Small factories save labor costs primarily (ROI in 18 months); large plants gain throughput boosts (ROI under 12 months). Match machine capacity to your true demand.

Bottleneck liberation economics

True gains come from flow acceleration positively. A Canadian recycler increased line speed 31% after installation. Their ROI came in 7 months – 3x faster than projected.

Capacity-based price tiers:

| Configuration | Daily Capacity | Typical Price Range |

|---|---|---|

| Basic | ≤ 2,000 boxes | $7,000-$12,000 |

| Standard | 2,000-10,000 | $18,000-$35,000 |

| Heavy Duty | 10,000+ | Custom quotation |

Underpowered units can cost more long-term surprisingly. Our engineers provide free demand assessments for clarity. WhatsApp us direct with your carton dimensions for exact recommendations.

Case Erector vs Manual Case Forming: Which Is Better?

Paper cuts and muscle strains plague workers monthly. Your accident reports reveal 73% occur during simple tasks. Repetitive motions harm health permanently.

Case erectors outperform manual labor beyond 500 boxes/day: 200% efficiency gain, near-zero error rates, and 50% lower operational costs reliably. Machinery is safer long-term.

Tipping point calculation

The 500-box rule holds practically. Below this, flexibility may favor humans. Above it? Automation always wins economically.

Daily output comparison:

| Metric | Manual Crew | Case Erector |

|---|---|---|

| 500 boxes | 6 worker hours | 20 minutes |

| 1,000 boxes | Requires overtime | 40 minutes |

| 3,000 boxes | Impossible (single shift) | 2 hours with 15 minute rest period |

Transition when output exceeds 500 boxes daily minimally. Counterfeit injury claims drop 100% with automation. Still hesitant? Let’s discuss scenarios: WhatsApp us direct.

Conclusion

Case erectors prevent injuries, reduce costs, and scale operations securely. Invest in both productivity and worker health confidently.