Manual box assembly creates bottlenecks in production daily. Delays frustrate teams and inflate labor costs. Choosing the right supplier solves this immediately.

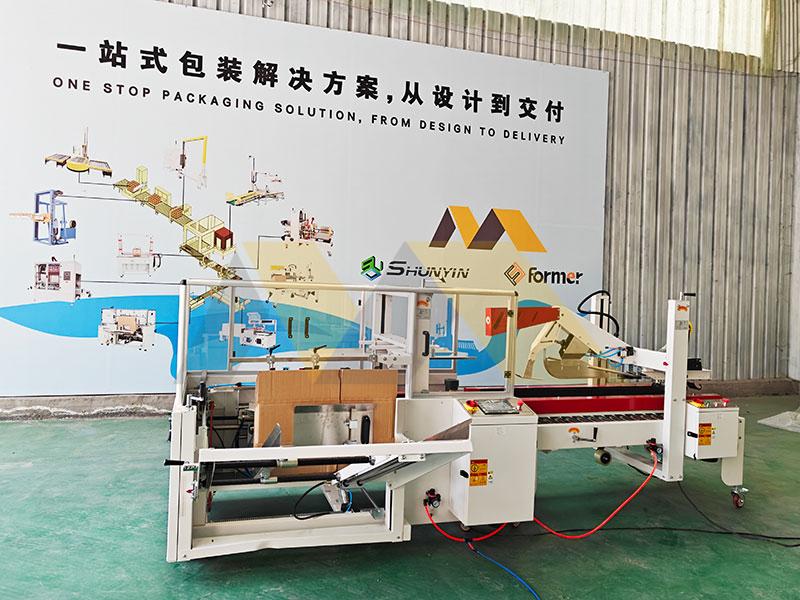

As China’s carton erector machine supplier, we manufacture and customize high-speed box-forming solutions. Our factory offers wholesale pricing, robust equipment, and handles global shipping certified to international standards for seamless imports.

Finding reliable suppliers demands careful verification. Let’s examine why specialized exporters make this process smooth.

Why Choose a Direct Carton Erector Machine Exporter?

Importing complex machinery alone risks costly delays. Customs misunderstandings and shipping damage occur frequently. Export specialists prevent these headaches at origin.

Exporters manage logistics, documentation, and quality checks pre-shipment. They consolidate cargo efficiently and navigate border procedures using pre-certified routes like Singapore’s Free Trade Port for duty savings.

Selecting an experienced exporter unlocks critical benefits during transit.

Cross-Border Efficiency Breakthrough

- Documentation Management: Export licenses, commercial invoices, packing lists

- Transport Optimization: Choosing sea/air combinations by cargo value

- Risk Mitigation: Marine insurance covering damage in transit

| Comparison of shipping methods: | Shipping Mode | Timeframe | Cost Impact | Our Recommendation |

|---|---|---|---|---|

| Full Container (FCL) | 35-45 days | Lowest $/unit | ≥10 machines | |

| Air Freight | 5-7 days | 4x premium | Urgent replacement parts | |

| Express Courier | 3-5 days | 8x premium | Prototypes/samples |

A North American distributor saved 19% on duties when we classified machines under HS Code 8422401000 through Singapore. Exporters understand tariff shift rules for origin certification. Discuss your destination country to strategize savings on WhatsApp.

How Does OEM Factory Status Enhance Carton Erector Quality?

Generic machines often fit poorly in unique facilities. Custom conveyors and control interfaces become expensive add-ons. Direct OEM manufacturers design from scratch.

As an OEM carton erector machine factory, we modify dimensions, power systems, and software according to your drawings. No middlemen ensures lower costs and precise implementation of technical requirements.

Full in-house control impacts machines at every level.

Proprietary Manufacturing Advantages

Three pillars guarantee quality consistency:

1. Design Collaboration Process

- Requirement analysis workshop (virtual/physical)

- CAD prototype simulation

- Material compatibility testing

2. Production Line Specialization

| Station | Capability | QA Checkpoints |

|---|---|---|

| Frame Welding | Robotic TIG precision | Laser alignment verification |

| Electrical | EU-standard wiring looms | IEC 60204-1 compliance test |

| Final Assembly | Modular buffer integration | Automated speed cycles |

3. After-Sales Infrastructure

- Spare parts inventory accessible worldwide

- Remote PLC diagnostics for repairs

Our recent Canadian client integrated special proximity sensors to interface with their ERP system without third-party programmers. Share your factory blueprints so we can discuss custom options face-to-face. WhatsApp consultations get priority design responses.

Can Wholesale Carton Erector Purchases Reduce Total Ownership Cost?

Retail machinery sourcing raises per-unit expenses drastically. Bulk orders often face unreliable stock availability. Direct factory wholesale channels solve both problems.

Wholesale carton erector machines offer 15-45% savings versus distributors. Larger quantities release economies of scale for accessories and future spare parts pricing locked in long-term contracts.

Volume purchasing requires strategic planning beyond price comparisons.

Cost Analysis Framework

Breakdown of multi-machine acquisitions:

| Initial Investment Protection | Units 1-5 | Units 6-10 | Units 11+ | |

|---|---|---|---|---|

| Machine Discount | 15% | 25% | Custom quote | |

| Accessory Pack | Basic | Enhanced | Premium | |

| Terms | 30% prepayment | 15% prepayment | LC at shipment |

Lifetime Value Enhancements

- Priority equipment maintenance schedules

- Dedicated account manager coordination

- Free operator training included ≥ 5 units

One Japanese trader now saves ₤12,000 annually on spare parts alone through our bulk agreement. We provide total cost modeling before quotation. Send your monthly throughput numbers via WhatsApp for an optimized package.

Why Must CE-Certification Be Your Minimum Machine Requirement?

Non-certified machines cause border rejections unexpectedly. Electrical faults risk operator injuries and create insurance complications. Compliance certifications are legal necessities.

Our CE-certified carton erector machines pass rigorous material, safety, and EMC tests. Certificates accompany shipments with documentation showing compliance with Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU.

Certification standards protect against catastrophic failures.

Compliance System Hierarchy

- Structural Integrity: EN ISO 12100 risk assessments

- Electrical Safety: IEC 60204-1 leakage prevention systems

- Noise Control: EN ISO 4871 under 70 dB(A)

| Testing verification steps: | Test Stage | Standard | Pass Criteria |

|---|---|---|---|

| Dielectric Strength | IEC 61131-2 | 1500V/10mA leak | |

| Emergency Stop | EN ISO 13850 | <0.5s response | |

| Entanglement Risk | EN ISO 13857 | Zero pinch points |

An Australian importer encountered zero customs examinations using our TUV-certified reports last quarter. We conduct pre-shipment witnessed tests via video call. Request our certification package containing test videos – simply WhatsApp "CE Proof" to begin.

How Do We Guarantee Reliable After-Sales Support Globally?

Remote support accessibility defines long-term machine performance. Time zone gaps delay critical troubleshooting. Our multilingual team provides 18-hour coverage daily.

Global technical centers stock spare parts worldwide for quick shipping. Maintenance contracts include video diagnostics within 4 hours for emergency breakdowns, minimizing overseas machine downtime.

Maintain machinery efficiency through structured service tiers.

Conclusion

Partnering with certified manufacturers combines technical excellence and export proficiency. We deliver tailored solutions ensuring operational excellence across diverse global markets.