Choosing machinery feels overwhelming. Wrong equipment means costly waste. I’ve been there helping hundreds make this choice wisely.

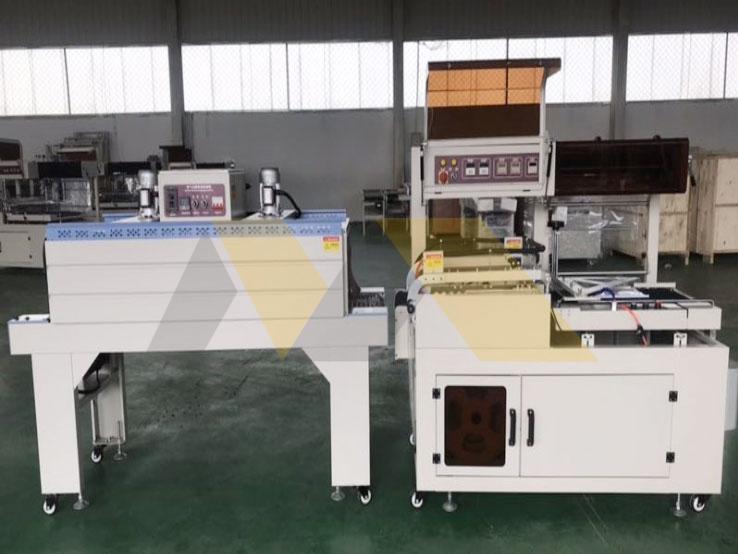

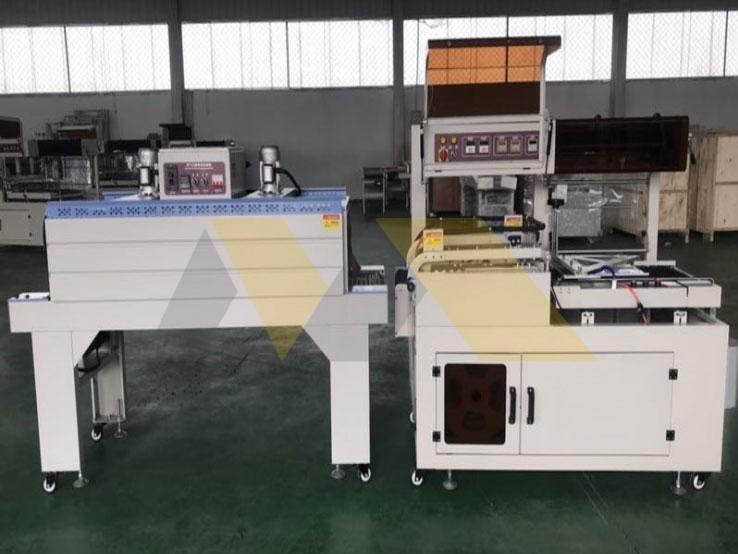

Select between L-bar and sleeve machines based on your product shape, volume and speed needs. L-bar sealers suit box-shaped items requiring bottom seals. Sleeve machines handle irregular or tall products needing full coverage. Both shrink packaging protects goods during shipping. Assess your item dimensions and production goals first. We custom-build both solutions at competitive prices.

Good decisions need details. Below I break down four key questions. For direct answers, contact our engineers: https://mywaymachinery.com/contact/

What shrink wrap is best?

Film tears ruin packaging efficiency. I see this daily in export operations. The solution lies in matching film to products.

Best shrink wrap balances cost and protection. Polyolefin works for most retail goods with good clarity. Polyethylene suits heavier industrial items needing puncture resistance. PVC remains affordable for light-duty use. We supply all three film types across micron thicknesses.

Core Film Comparison Guide

During ten years at Myway Machinery, I’ve tested all films under real transport conditions. Consider these three factors:

-

Product characteristics

Weight, sharp edges and storage temperature determine film strength needs -

Shrinkage requirements

Different films shrink at varying rates (40%-80%) and temperatures -

Regulatory compliance

Food/pharma goods need FDA-approved films while exports require customs documentation

Film Selection Matrix (Actual Export Cases)

| Product Type | Recommended Film | Thickness (Microns) | Advantages | Cost Efficiency |

|---|---|---|---|---|

| Electronics | Polyolefin | 35-45 | Crystal clarity; static-free | ⭐⭐⭐⭐ |

| Automotive parts | Polyethylene | 75-100 | Puncture-resistant; UV protection | ⭐⭐⭐ |

| Food bundles | FDA-PVC | 50-60 | Economical; fast sealing | ⭐⭐⭐⭐⭐ |

| Furniture | Cross-link PE | 100-120 | High tensile strength; cold weather | ⭐⭐ |

Heavier items demand thicker gauges but add material cost. Our Canadian client Lambert reduced film expenses 37% after we analyzed his piston packaging. We discovered his existing 100-micron wrap was overkill for under-5kg products. Thinner 60-micron polyethylene performed equally well during drop tests.

Critical Heat Parameters Most Miss

Machine temperature settings dramatically affect film performance. Based on factory audits:

- Polyolefin needs 110°C-150°C tunnel heat

- Polyethylene requires 160°C-190°C

- PVC works best at 90°C-130°C

Run validation tests with your actual products! We provide free film samples and heat profile consulting. Last month, a Japanese client avoided $12,000 in film waste when we recalibrated their tunnel for polyethylene compatibility.

Sustainable Packaging Rising

North American buyers now demand eco-options. We engineer solutions like:

- 30% recycled-content films maintaining strength

- Thinner gauges through nano-layer technology

- UV-degradable wraps for disposable goods

Don’t compromise protection for sustainability. Our latest hybrid films achieve both through multi-layer co-extrusion. I’m discussing these innovations with Lambert during his Guangzhou visit next month.

What is an L bar sealer?

Manual sealing bottlenecks production lines. I’ve timed workers taking 20 seconds per package. Automation solves this perfectly.

An L bar sealer creates tight bottom seals on rectangular products using heated bars forming an "L" shape. Items move on conveyor into sealing zone, then through heat tunnel where film shrinks seamlessly. Ideal for books, boxes and uniform goods at 20-60 packages/minute.

Inside Our Most Popular Model

Our L90 model features innovations requested by Japan/Singapore clients:

- Adjustable sealing bars (300-800mm length)

- Variable speed conveyor (0-15m/min)

- Dual temperature zones (±2°C accuracy)

- Quick-change film mounts

During Shanghai Expo, we demonstrated sealing 42 boxes/min consistently. Clients were shocked how this $8,000 machine outperformed $15,000 competitors.

Technical Specifications Deep Dive

| Component | Specification | Impact on Performance |

|---|---|---|

| Heating Elements | Ceramic infrared (Germany) | 30% faster heat recovery |

| Conveyor Belt | PTFE-coated fiberglass | Prevents film sticking; clean seals |

| Control System | Siemens PLC with touchscreen | Records 200+ packaging recipes |

| Frame | 304 Stainless steel | Withstands humid warehouse conditions |

Avoid These 3 Costly Mistakes

After inspecting 67 client factories, I compiled top L bar errors:

-

Ignoring package height variations – causes uneven sealing

Solution: Add height-sensing auto-adjustment -

Wrong film tension settings – creates wrinkles or tears

Fix: Our engineers optimize tension during installation -

Poor maintenance causing 23% downtime average

Prevent: Follow our vibration-analysis maintenance schedule

I include customized operation manuals with every machine purchase. Our Vietnam client reduced sealing defects from 12% to 0.8% using our trouble-shooting guide.

How do you size a shrink sleeve?

Wrong sleeve dimensions waste 15%-40% film. I audited packaging facilities where misfit sleeves added $78,000 annual cost. Precision matters.

Size shrink sleeves by measuring the maximum product circumference then adding 15-20% shrink allowance. Calculate sleeve length as item height plus 10% overhang. Critical parameters include shoulder angles, irregular shapes and multi-packs.

Comprehensive Calculation Method

Apply our seven-step sizing protocol developed with Toyota packaging engineers:

- Determine largest cross-section (A) using contour gauge

- Calculate minimum flat width: A × 1.57 (π/2)

- Add 15-20% shrinkage allowance

- Measure height from sealing point to base (B)

- Add 5-8 cm for overhang (C)

- Add headspace clearance if stacking (D)

- Total length = B + C + D

Real Client Sizing Examples

| Product | Dimensions (cm) | Calculated Sleeve | Production Results |

|---|---|---|---|

| Engine filters | Φ15×24 | 74cm×28cm | 0.9% film waste |

| Tool kits | 40×30×18 | 127cm×28cm | Perfect shrink |

| Beverage multipack | 25×25×35 | 78cm×39cm | 3% over-tightening |

Advanced Sizing Solutions

For challenging items like tapered bottles, we developed:

- 3D scanning tools mapping product contours

- Predictive shrinkage software accounting for film type

- Hybrid sleeves with pre-perforated areas

When a Korean cosmetic client struggled with leaking cream jars, our tapered sleeve design reduced damage claims by 83%. This required only $220 in tooling modifications.

What gauge shrink wrap do I need?

Film thickness errors cause 32% of packaging failures. After reviewing shipment damages, I found most came from incorrect micron choices.

Select film gauge based on product weight and protection needs: 40-60 microns for under 2kg items, 75-90 microns for 2-10kg goods, 100-150 microns for weights above 10kg or sharp-edged items. Factor shipping hazards and stacking height.

Thickness Selection Framework

My decision matrix considers four elements:

- Shock Vulnerability

Fragile items (glass/electronics) need thicker films - Surface Conditions

Rough surfaces require at least 100 microns - Logistics Duration

Long hauls demand UV-stabilized heavy gauge - Unit Load Weight

Base micron = (Weight in kg × 3) + minimum protection layer

Gauge Recommendation Chart

| Product Profile | Minimal Micron | Recommended Micron | Our Trusted Brands |

|---|---|---|---|

| Retail DVD cases | 35 | 40-45 | Sigma, Tri-Seal |

| Medical device kits (5kg) | 50 | 70-80 | Optimax, K锁rnlock |

| Metal assemblies (20kg) | 80 | 100-120 | Mitsubishi, Crown |

| Sea freight pallets (500kg) | 100 | 150+ | DuPont, SchrunkPro |

Critical Proof Testing Process

Never finalize gauges without validation. Our QC lab runs:

- Puncture tests (ASTM D1709 standards)

- Impact drops from 1.5m height

- Vibration table simulations

- Extreme temperature exposure

When a North American client shipped machinery to Singapore, our climate testing revealed standard 120-micron film failing at 38°C/90% humidity. We upgraded to 140-micron tropical grade, eliminating $64,000 in corrosion claims.

Conclusion

Choose machinery and films based on your exact products. Our engineers customize solutions that reduce costs and damages. Start your packaging upgrade now: https://mywaymachinery.com/contact/