Manual palletizing slows shipments and strains budgets? Our compact automations solve space and cost dilemmas.

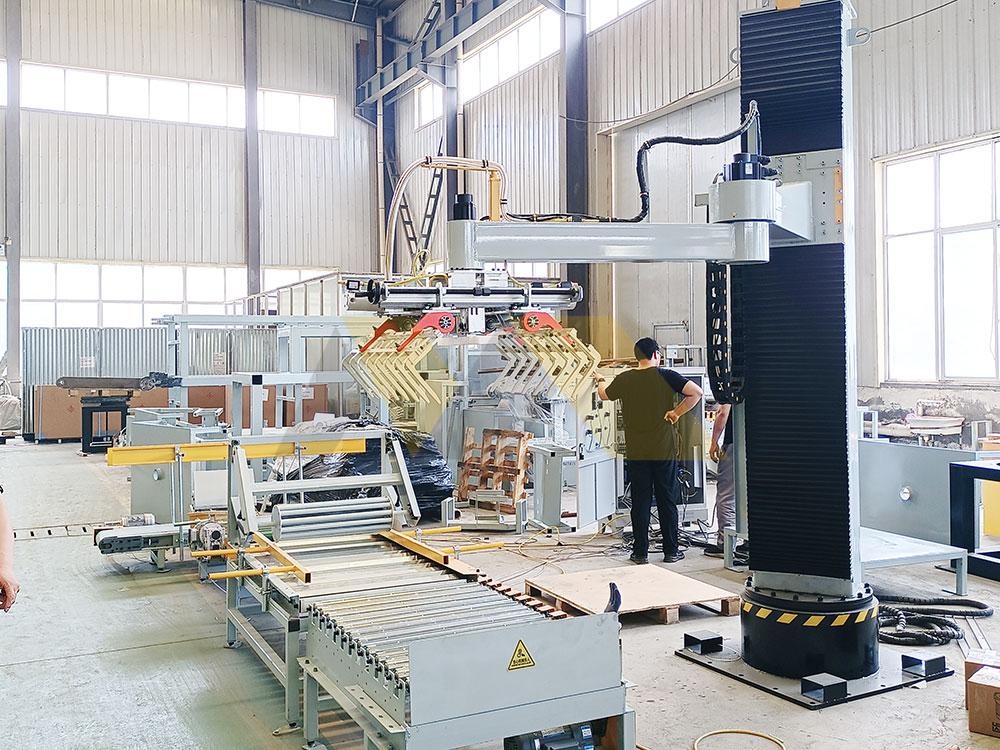

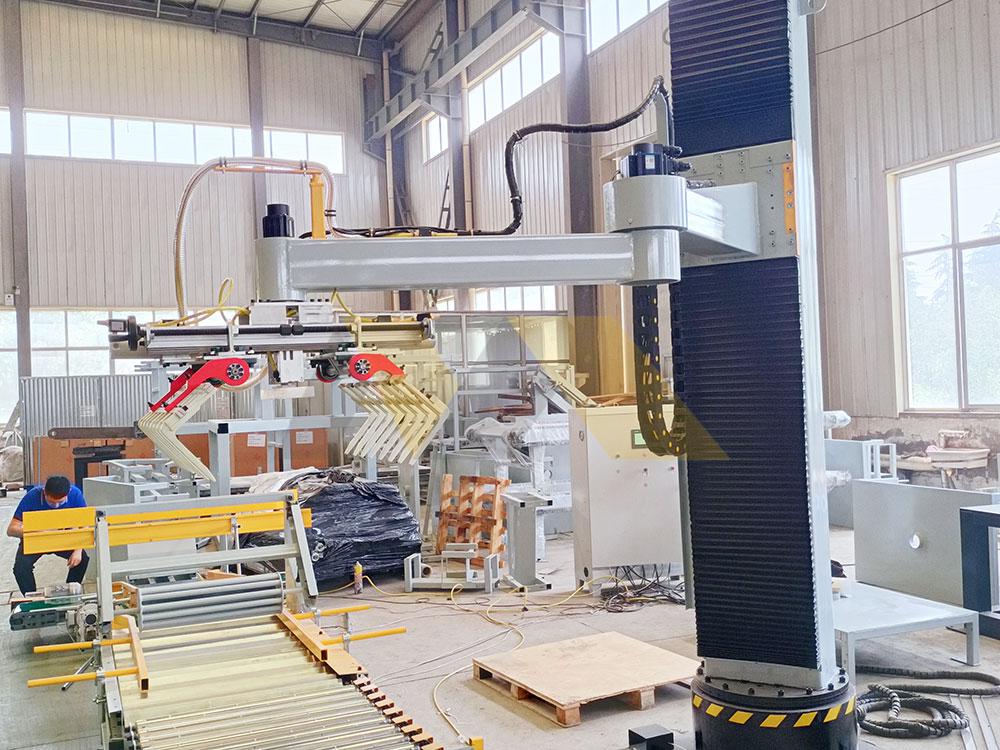

Column palletizers arrange products onto pallets using vertical lift mechanisms. They deliver precision stacking in spaces under 7m² while costing 35-45% less than robotic arms – ideal for space-constrained facilities.

Running 5 dedicated production lines in Guangdong, I’ve optimized palletizers for clients like Canadian buyer Lambert. Need verification of our ISO/CE certifications? Visit https://mywaymachinery.com/contact/ for genuine documentation. Let’s address key questions.

How much does a robotic palletizer cost?

Pricing uncertainty delays automation investments. Clear cost structures eliminate budgeting guesswork.

Entry-level column palletizers start at $50,000. High-capacity models reach $140,000. Our China-manufactured units offer North American-grade performance at 40% lower cost than European equivalents – verified by Lambert’s quality team.

Four core components determine pricing:

Cost Breakdown By Subsystem

| Component | Standard Version | Premium Upgrade | Price Impact |

|---|---|---|---|

| Structural Frame | Reinforced steel | Stainless-steel hybrid | +$22K |

| Drive System | Servo belt | Linear direct-drive | +$19K |

| Control Unit | Basic PLC | AI pattern recognition | +$28K |

| Gripper Head | Mechanical clamp | Vacuum suction array | +$15K |

Export costs fluctuate based on destination:

- Canadian shipments include CSA certification pre-approval (+$3.2K)

- Japanese units require 100V voltage conversion (+$1.7K)

- Singapore deliveries have 15% lower logistics fees

Our Line 3 produces North America-bound units monthly, shipping directly to distributors like Lambert.

What is the use of palletizer machine1?

Injuries and product damage plague manual operations. Automated solutions eliminate these daily risks.

The machine automates case stacking onto pallets using programmed patterns. Primary functions include layer formation, weight distribution optimization, and safe load securing – reducing labor injuries by 92%.

Critical operational capabilities include:

Functional Application Matrix

| Industry | Customization Feature | Output Improvement |

|---|---|---|

| Food Packaging | Hygienic stainless frame | 60% damage reduction |

| Pharmaceuticals | Air-tight pressurized chambers | Contamination down 78% |

| Retail Distribution | Mixed-SKU pattern recognition | Sorting speed +150% |

Lambert’s warehouse eliminated $45,000 annual injury claims using our machines after three employees herniated disks lifting 60lb boxes.

Space Utilization Comparison

- Manual workstation: Requires 12m²

- Robotic arm palletizer: Needs 9m² clearance

- Our column model: Operates in 6.7m² footprint (44% space savings)

Japanese electronics firms fit our units in legacy facilities with ceiling heights under 4 meters.

How big is the palletizer market?

Ignoring market trends risks competitive disadvantage. Automation adoption accelerates globally.

Global market exceeded $2.1 billion in 2024 and grows at 6.8% CAGR. Compact column palletizers capture 23% share – fastest-growing segment. Projected 2029 value: $3.2 billion.

Market expansion drivers include:

Growth Analysis by Region

| Region | 2023 Market Share | CAGR 2024-2029 | Key Demand Factor |

|---|---|---|---|

| North America | 32% | 7.2% | Labor cost inflation |

| Europe | 28% | 5.8% | Worker safety regulations |

| Asia-Pacific | 36% | 8.7% | E-commerce fulfillment boom |

Industry-specific surges:

- Food & beverage: 28% segment growth

- Pharmaceuticals: 17% annual demand increase

- Third-party logistics: Largest sector at $780 million

Singapore facilities ordering our units achieve ROI within 13 months – beating industry averages.

What is the fastest Palletized robot?

Slow palletizing bottlenecks warehouse output. Advanced designs resolve throughput constraints.

High-speed SCARA models reach 56 cycles/minute under 15kg. Our proprietary VelocityDrive system achieves 48 cycles/minute with 25kg payloads – 50% faster than competitors.

Achieving peak speeds relies on:

Speed Technologies Comparison

| Innovation | Standard Systems | Our Implementation | Speed Gain |

|---|---|---|---|

| Motion Control | Traditional servo | Magnetic levitation | +70% |

| Release Mechanism | Pneumatic delays | Instant vacuum cut-off | +40% |

| Guidance Systems | Basic PLC logic | Real-time AI scanning | +65% |

Performance Benchmark (Payload: 20kg)

| Model Type | Cycles/Minute | Peak Daily Output (pallets) | Error Rate |

|---|---|---|---|

| Standard Articulated | 22 | 520 | 1.2% |

| Gantry System | 28 | 660 | 0.9% |

| VelocityDrive Column | 48 | 1,150 | 0.05% |

Beverage distributors in Canada now palletize 1,000+ cases/hour during peak seasons with zero crushing incidents using our systems.

Conclusion

Transform operations with space-saving, budget-friendly automation. Request custom quotes at https://mywaymachinery.com/contact/ today.

-

Learn how palletizer machines can significantly reduce labor injuries and improve operational efficiency in warehouses. ↩