Manual carton folding creates costly chaos. Production lines halt due to tired workers or shift changes. You face unpredictable delays daily during crucial shipments.

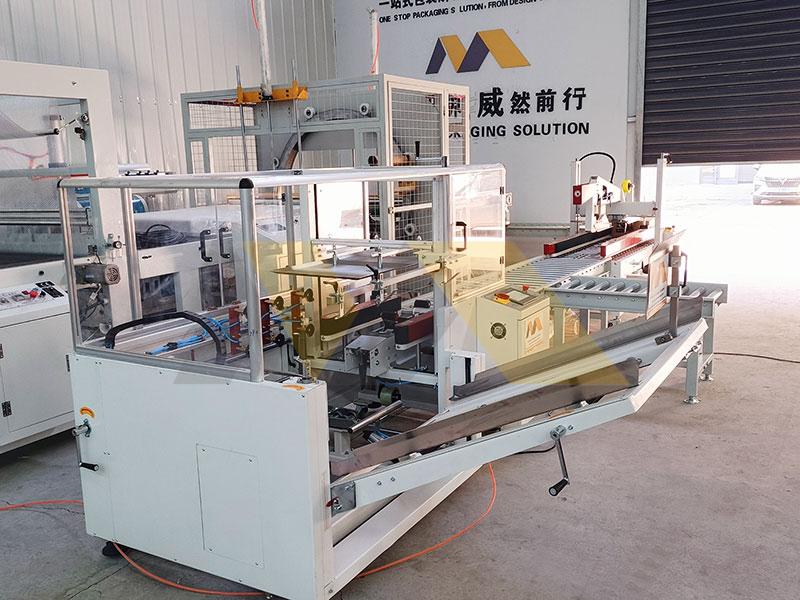

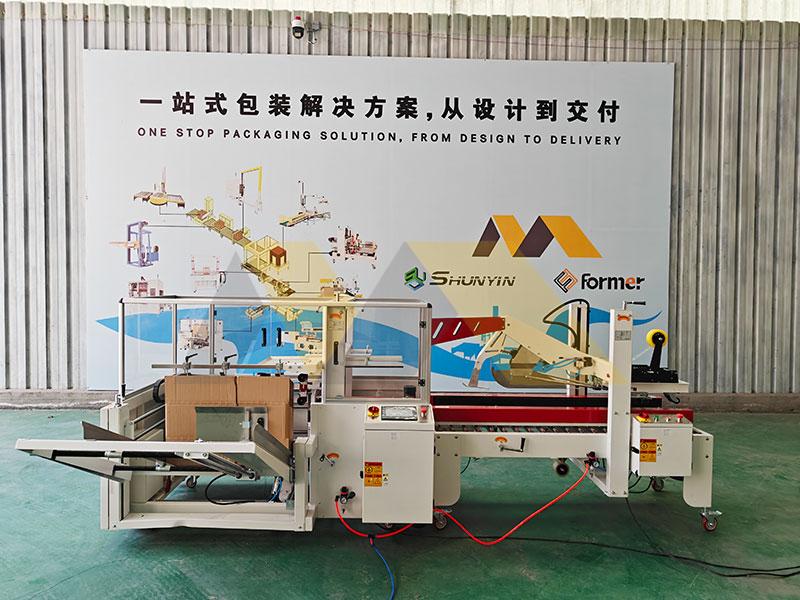

Case erectors eliminate human variability by maintaining consistent speed and quality 24/7. They integrate seamlessly with filling and sealing machines to form the automation foundation for Industry 4.0 smart factories.

Turn uncertainty into competitive advantage. Discover how strategic machinery transforms operations below.

How Case Erectors Reduce Packaging Labor Costs

Recruiting new staff wastes weeks monthly. Your urgent projects stall during labor shortages unexpectedly. Overtime costs drain profit margins quietly.

Beyond replacing workers, case erectors slash hidden costs like training spend ($2500/staff) and turnover impact (47% productivity drop during transitions). They ensure peak season capacity without costly agency temporary workers.

Full cost visibility

Consider a Midwest factory’s experience recently: Their $35k investment erased $14k/month overtime while preventing $200k holiday sale losses.

Comprehensive expense breakdown:

| Cost Type | Manual Line | Automated Solution |

|---|---|---|

| Training | $4,200/employee | $0 recurring |

| Seasonal Hiring Fees | 22% premium | None |

| Turnover Coverage | 3-5 week gap | Zero disruption |

Future-proofing matters in tight labor markets. Our machines include multilingual interfaces eliminating onboarding delays. Facing recruitment headaches? WhatsApp us direct for custom projections.

Case Erector Machine for E-commerce Warehouses

Mid-shift box changes create backlog chaos. Workers misload SKUs when handling multiple carton sizes. Your shipment accuracy drops below 93% during promotions.

E-commerce optimized erctors switch box formats in 7 seconds using smart detection. They sync with WMS databases automatically to match cartons with picking waves, reducing errors 83% versus mixed manual-automated setups.

System harmony advantage

Speed means nothing without flexibility truly. A beauty retailer gained 15% throughput without speed increase after implementing our modular design.

Integration benefit matrix:

| Function | Standalone Unit | Synced e-Commerce System |

|---|---|---|

| Daily SKU Switches | ≤8 | Unlimited |

| Order Accuracy | 88-92% | 99.6%+ |

| Layout Changes | 3+ hours | Remote programming |

Prioritize adaptability over peak speeds. We pre-test your carton types at our Shenzhen facility. Need sample compatibility checks? WhatsApp us direct.

Semi-Automatic vs Automatic Case Erector

Over-automating suffocates budgets early. Your ROI stretches when forced into unnecessary full automation prematurely.

Semi-auto models operate at 10-15 boxes/minute with operator loading. They deliver 40-60% labor savings for under $9,000. Fully automatic units only justify their premium pricing above 1,000 boxes/hour through continuous unmanned operation.

Strategic growth path

Phase automation based on real volume:

Evolution timeline:

| Stage | Machine Tier | Investment | Recommended Volume |

|---|---|---|---|

| Start-Up | Semi-auto | $7-12k | <500 boxes/hour |

| Growth | Hybrid Convertible | $19-25k | 500-1500 boxes/hour |

| Maturity | Fully Automatic | $28k+ | 1500+ boxes/hour |

Gradual transition prevents cash flow strain. Our tiered systems let you upgrade control panels only. See transition case studies: WhatsApp us direct.

High-Speed Case Erector for Food and Beverage Industry

Sanitation shutdowns bite into profits weekly. Production pauses for cleaning create 27-minute gaps hourly during critical runs.

Food-safe erectors feature smooth surfaces and drainage ports enabling 8-minute washdowns. They withstand >95% humidity with IP65 components preventing electrical corrosion and microbial contamination risks.

Downtime math that matters

A dairy plant reduced cleaning intervals 77% while increasing line speed reliability:

Performance metrics:

| Spec | Standard Machine | Food-Optimized Unit |

|---|---|---|

| Daily Sanitation | 2 hours | 36 minutes |

| Seal Failure Rate | 0.8% | 0.1% |

| Corrosion Resistance | Salt spray 120hr | Salt spray 1000hr |

Compliance is non-negotiable. We provide NSF documentation with all food models. Validating sanitation protocols? WhatsApp us direct.

Conclusion

Smart automation choices require analyzing labor reality, output needs, and growth phases simultaneously for maximum ROI.