Struggling with box assembly delays? Manual carton folding wastes hours daily. Our machines solve this, cutting setup time by 80%.

A reliable carton case erector supplier offers customizable machines with installation support. I ensure every Myway unit comes with 24-month warranty and live training sessions via WhatsApp – message us for instant solutions.

Slow packaging lines drain profits. Next, we explore machine options to match your needs.

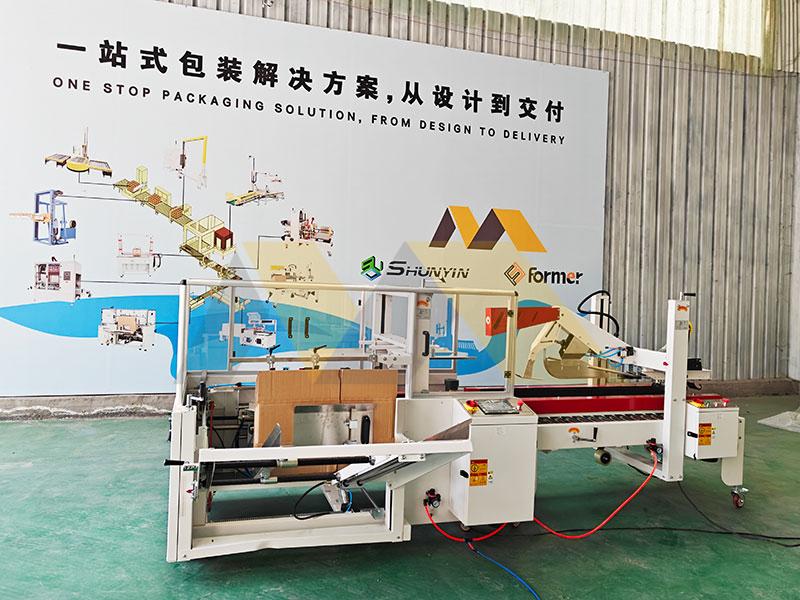

Automatic Case Erector Machine?

Frustrated by manual labor costs? Human errors increase waste. Our automation handles complex folding accurately.

Automatic case erectors process 15-25 boxes/minute with self-adjusting settings. Myway’s models include error alerts and reduce labor needs by 90% – send us your box dimensions for a demo video.

Maximizing Automation Value

Key Performance Considerations

Consider these three priorities:

-

Integration Capability

- Our machines sync with PLC systems for $500 extra

- Standalone units ideal for simple setups

-

Throughput vs Price Balance Speed Tier Output (Cases/Min) Price Range Best For Basic 15-18 $15-20K Small facilities Enhanced 18-22 $20-28K Medium lines Premium 22-25 $28-35K 24/7 operations -

Maintenance Simplicity

- Tool-free access panels save repair hours

- Remote diagnostics signal issues early

Japanese client feedback: "Downtime dropped from 3 hours to 20 minutes weekly." Share your shift schedule for our free maintenance planner. Reach us instantly via WhatsApp!

Semi Automatic Case Erector?

Limited floor space causing headaches? Large machines won’t fit small workshops. We offer compact solutions.

Semi-automatic erectors handle 8-12 cases/minute with manual feeding. I price them at $9,000-$14,000 – half the cost of full automation but faster than manual labor.

Optimizing Semi-Automated Systems

Application Scenarios Analysis

Certain operations benefit more from semi-auto:

- Material Variability: Manual feeding adapts to irregular cardboards

- Budget Constraints: 60% cheaper than automated equivalents

- Transition Phases: Train teams before full automation

Upgrade Possibilities Matrix

| Feature | Add-on Cost | Labor Reduction |

|---|---|---|

| Foot pedal operation | $200 | 15% operator effort |

| Laser guide positioning | $450 | Faster alignment |

| Automated tape dispenser | $880 | Eliminate sealing station |

Recently helped a Canadian distributor retrofit existing machines for $3,200 saving $15,000 for the client. Send photos of your production area for customized recommendations.

High Speed Case Erector for Packaging Line?

Bottlenecks slowing shipments? Standard machines can’t handle peak demand. Our high-speed options keep pace.

High-speed erectors process 30-40 cases/minute for continuous lines. Myway units maintain ±0.3mm precision at maximum speed – contact us for stress test results.

Engineering for Speed Without Compromise

Stability Requirements Checklist

High velocity demands robust engineering:

- Vibration control through reinforced frames

- Servo motors with torque safeguards

- Infrared jam detection stopping in 0.5 seconds

Maintenance Protocols Table

| Component | Inspection Frequency | Replacement Cost |

|---|---|---|

| Drive belts | Weekly | $80-120 |

| Suction cups | Monthly | $30-50 |

| Guide rails | Quarterly | $200-300 |

North America Case Study

Toronto facility upgrade:

- Previous speed: 22 cases/minute

- After Myway installation: 38 cases/minute

- Profit impact: +$48,000 monthly

How many boxes do you process hourly? We’ll calculate your exact savings. Reach out today via WhatsApp.

Tape Sealing Case Erector Machine?

Reinforcement failures ruining shipments? Weak seals cause box collapses. Our integrated sealing prevents this.

Tape sealing erectors apply glue-reinforced tape during assembly. I design these to withstand 110kg pressure with built-in tension control – request our load-test certification now.

Sealing Technology Advancements

Material Compatibility Guide

| Match tape types to your packaging needs: | Tape Type | Max Weight | Temp Range | Cost/Meter |

|---|---|---|---|---|

| Acrylic | 40kg | -10°C~60°C | $0.08 | |

| Hot-melt | 80kg | 0°C~80°C | $0.14 | |

| Reinforced | 120kg | -30°C~100°C | $0.23 |

Critical Design Differences

- Automatic glue application prevents skipped seals

- Precision rollers adapt to uneven surfaces

- Touch-free sensor detection avoids tape waste

Installation Quick Tips

- Allow 50cm clearance behind machine for maintenance

- Position near air compressor

- Train operators on emergency cut-off switches

Singapore electronics exports saw 99.98% seal integrity after installing our machines. Forward your box specifications for a free engineering review.

Conclusion

Select specialized carton solutions matching your exact needs. I provide precision manufacturing support – message us direct for immediate answers.