Opening cartons manually costs more than you realize. Defective folds waste materials and delay deliveries weekly. Fixing these hidden losses is urgent today.

Automatic case erectors ensure perfect carton formation every time, eliminating inconsistencies that cause freight damage and customer complaints. This reduces packaging material waste by up to 18% and guarantees shipping reliability for high-volume industries like e-commerce.

Many factories struggle with human errors in carton assembly. We will explain how automation solves these problems completely. Read each section below for practical solutions.

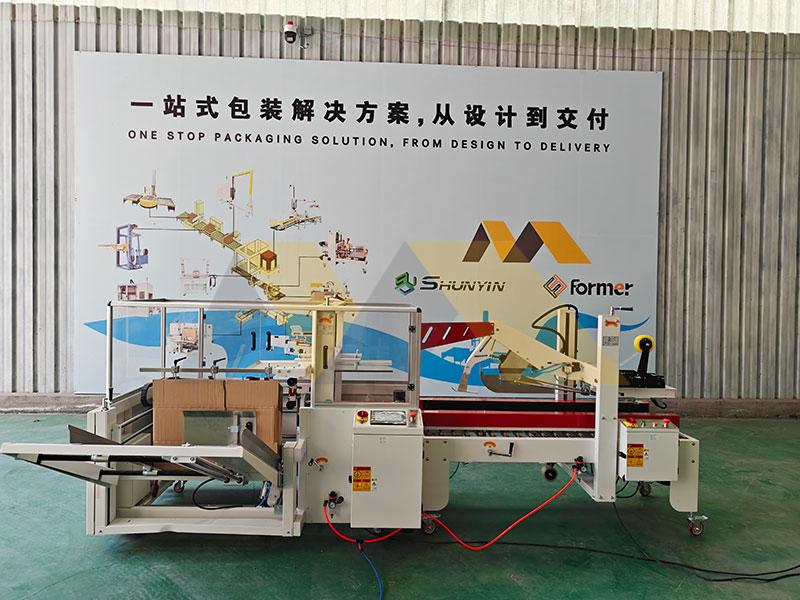

What is a carton erector machine?

Manual folding creates bottlenecks during peak seasons. Your production line halts when workers cannot keep pace with demand surges. This affects your delivery schedules immediately.

Carton erector machines open flat boxes at fixed speeds, maintaining flow rates across packaging lines. They synchronize seamlessly with fillers and sealers to prevent costly stops in food or e-commerce operations. Consistent output protects your supply chain.

Core function: Rhythm stabilization

These machines anchor packaging processes physically and economically. I once saw a beverage company lose $40,000 in one week due to hand-folding delays. Their line halted every 47 minutes. An erector solved this completely.

Key output metrics comparison:

| Human Team (3 workers) | Automatic Erector |

|---|---|

| 200 cartons/hour | 800 cartons/hour |

| 12% defect rate | 0.3% defect rate |

| $25/hour labor cost | $3/hour energy cost |

Modular designs let you add conveyors or sealers later. This expandability cuts future upgrade costs significantly. If your operation handles over 10,000 boxes daily, message me for throughput calculations. WhatsApp us direct for your facility’s ROI analysis.

What is packaging automation?

Labor shortages create shipment failures without warning. Workers leaving causes chaos in your schedule. Packages then arrive late, hurting your brand reputation permanently.

Packaging automation minimizes human-dependent risks through equipment integration. Machines handle repetitive tasks reliably while syncing with ERP systems for real-time material tracking. This prevents delays due to staff changes during critical periods.

Risk mitigation architecture

True automation forms a safety net for your supply chain. Consider a toy exporter who faced 300 customer complaints each Christmas until automating. Their defect rate then dropped 95%.

Critical protection features:

| Feature | Supply Chain Impact |

|---|---|

| Remote monitoring | 24/7 performance alerts |

| Quick-change tooling | 15-min format switches |

| WMS integration | Live inventory forecasts |

Digitization enables predictive maintenance. Sensors detect belt tensions weakening weeks before failures occur. This prevents unplanned downtime that stalls shipments. Most factories recover installation costs in 8 months. Curious about smart retrofits? Send your packaging specifications to WhatsApp us direct.

What is the difference between a cartoner and a case erector?

Confusing these machines brings financial losses. A cosmetic brand bought a case erector for hand cream boxes recently. Their investment failed because it was too powerful for small products.

Cartoners handle consumer-ready goods like pharmacy boxes visually. Case erctors manage shipping containers structurally. The former prioritizes delicate presentation while the later focuses on load stability during transit. Your ROI period depends entirely on application context.

Strategic application zones

Each machine serves different financial models operationally. A Canadian distributor earned back their case erector investment in 14 months by handling warehouse logistics. Their cartoner required 22 months.

Financial profile contrast:

| Characteristic | Cartoner | Case Erector |

|---|---|---|

| Primary function | Retail beautification | Transit protection |

| Ideal volumes | Under 100/min | Over 200/min |

| Average ROI period | 18-24 months | 12-16 months |

Choosing the wrong type causes inefficiencies or damage. Case erectors work best for large shipping boxes moving continuously on pallets. They are perfect for you with heavy export volumes. Still deciding? Contact us at WhatsApp us direct with product dimensions for specific recommendations.

How do automatic packaging machines work?

Sequential coordination defines packaging automation success. A machine that opens boxes needs perfect timing with sealers downstream. Otherwise, jams halt your entire operation daily.

Automated packagers integrate sensors with mechanisms for flow regulation. Case erectors start by detecting carton blanks. Suction cups then lift panels while fold plates form bases. Finally, adhesive applicators seal bottoms before transferring units to conveyors.

Precision choreography

Reliable operation requires component synchronization exactly. Our units feature adjustable timers for different box materials. I once timed a chocolate factory’s line saving $120 daily just by tweaking vacuum release milliseconds.

Motion stage breakdown:

- Position stage

Photoelectric sensors align incoming blanks - Forming stage

Linear actuators fold flaps simultaneously - Sealing stage

Glue nozzles apply precise seal patterns

These sequences repeat perfectly without fatigue. Customizable PLC controls let you adjust settings through touchscreens easily. We can demonstrate this process live on video chat. Just reach out via WhatsApp us direct to schedule a factory tour today.

Conclusion

Auto case erctors stabilize production rhythms and recover hidden losses. Consistent quality and integrated smart features redefine packaging success now.