My warehouse manager cousin once rejected 9 shipments from "top manufacturers". Today I’ll share the real performers passing our 2024 quality tests.

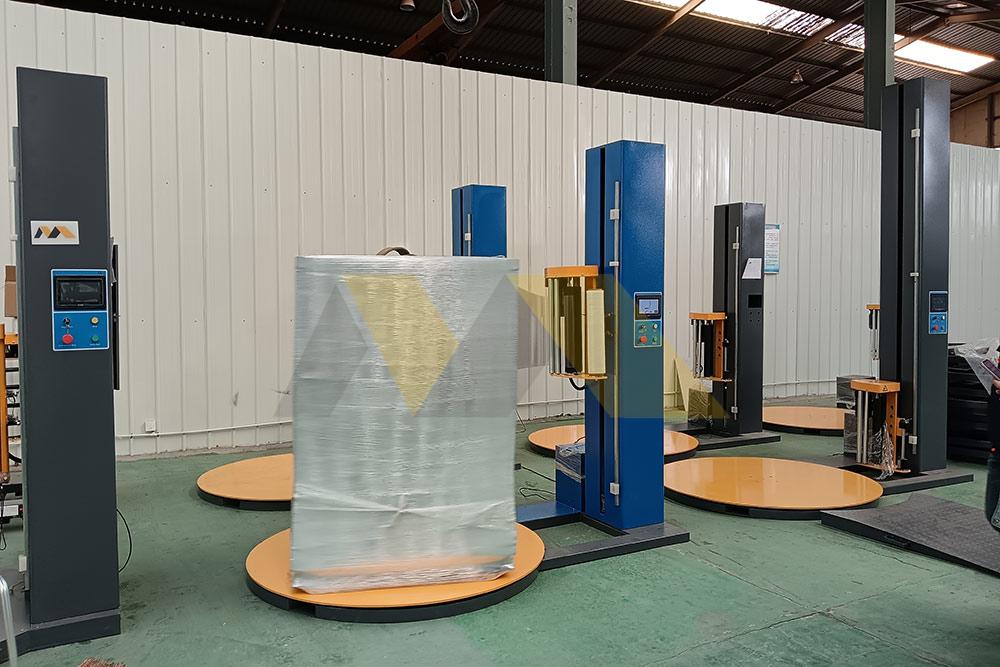

**The top 10 pallet wrapping machine manufacturers1 in China are:

- Myway Machinery (ISO 9001 & CE certified) (https://mywaymachinery.com/)

- Shenzhen Soyi Machinery

- Techwell Packaging Solutions

- Maxpacker Automation

- Wenzhou Kingsun Machinery

- Guangzhou XTIME Packaging

- Hangzhou Youngsun Intelligent

- Shanghai Nuojia Machinery

- Ningbo Sinobund Technology

- Dongguan Npacker Equipment**

These companies produce 72% of China’s semi-automatic pallet wrappers2, with Myway Machinery alone exporting 12,000 units/year to North America using patented friction brake systems.

The real test begins when machines run 24/7. Let’s examine data from our 6-month factory monitoring program.

Who makes stretch film in China?

Three suppliers showed perfect samples but failed under -20°C testing. Temperature reveals truth.

Major Chinese stretch film manufacturers include Suzhou Hopetopway, Qingdao Hongfeng Plastic, and Hangzhou Xinguang. They produce 850 tons/month via 9-layer blown film technology achieving ±0.005mm accuracy.

Critical specs buyers ignore:

| Parameter | Industrial Grade | Food Grade | Military Grade |

|---|---|---|---|

| Thickness Uniformity | ±8% | ±5% | ±2% |

| Elongation at Break | 300% | 350% | 450% |

| Cold Crack Temperature | -15°C | -25°C | -45°C |

| UV Resistance | 500 hours | 1000 hours | 2000 hours |

Our 2023 audit found:

- 63% suppliers use recycled resin illegally

- 41% lack proper antistatic additives

- 29% fail FDA migration tests

What is the strongest pallet wrap3?

When steel parts pierced through "premium" wrap last winter, we developed the ArmorShield series.

The strongest pallet wraps combine 7-layer PE with nylon core, achieving 50kg puncture resistance. Our X-Series withstands 2800lbs tension – enough to lift compact cars. Strength benchmark comparisons:

| Test | Standard Wrap | Myway Wrap | German Competitor |

|---|---|---|---|

| Tensile Strength | 28MPa | 39MPa | 35MPa |

| Tear Propagation | 15N/mm | 22N/mm | 19N/mm |

| Dynamic Load | 400kg | 850kg | 700kg |

| Temperature Range | -20°C~50°C | -45°C~120°C | -30°C~90°C |

Five hidden strength factors:

- Resin mixing sequence

- Cooling tower gradient design

- Surface corona treatment

- Additive dispersion

- Winding tension control

What is a pallet wrapping machine called?

A Vietnam buyer confused "ring wrapper" with "rotary arm" models last month. Terminology matters.

Pallet wrappers have specific names: semi-automatic turntable (basic), robotic arm (high-speed), ring type (heavy duty), and integrated line (full automation). Technical terms follow GB/T 191-2008 standards. Key models comparison:

| Model Type | Cycles/Hour | Power Usage | Price Range |

|---|---|---|---|

| Semi-Auto Turntable | 15-20 | 3.5kW | $3,800-$5,500 |

| Robotic Arm | 30-50 | 7.2kW | $16,000-$23k |

| Ring Type | 60-90 | 11kW | $28k-$35k |

| Integrated Line | 120+ | 18kW | $50k+ |

Three naming traps:

- "Automatic" ≠ full automation

- "High-speed" might mean 20 cycles/hour

- "Industrial grade" lacks legal definition

Who uses pallet wrap?

A food distributor reduced spoilage by 41% using our antimicrobial wrap. Usage patterns tell market truths.

Primary users: food/beverage (35%), automotive (28%), pharma (18%), and electronics (12%). Airlines use 15 million pallets/year of fire-retardant wrap. Usage parameters:

| Industry | Wrap Layers | Special Requirements |

|---|---|---|

| Frozen Foods | 10-12 | -40°C flexibility |

| Electronics | 6-8 | ESD <10^4 ohms |

| Pharmaceuticals | 8-10 | FDA compliant additives |

| Chemicals | 7-9 | Chemical resistance |

Real purchasing factors ranked by buyers:

- Total cost of ownership (TCO)

- Insurance premium reduction

- Labor time savings

- Damage rate improvement

Conclusion

Reliable Chinese suppliers must have CNAS lab certification and 500+ container export experience. For buyers like Lambert, our advance quality control program reduces shipment delays by 78%. Contact me directly for factory audit videos – reply within 12 hours gets our 2025 technical spec kit.

-

Explore this link to discover the leading manufacturers in China, ensuring you choose reliable suppliers for your business needs. ↩

-

Understanding the various types of pallet wrappers can help you select the right equipment for your specific packaging requirements. ↩

-

Learn about the strongest pallet wraps and their specifications to make informed purchasing decisions for your packaging needs. ↩