Manual wrapping strains workers and slows output. As a factory owner, I’ve seen countless businesses struggle needlessly. Semi-automatic machines bridge efficiency gaps. Discover why they dominate SME logistics.

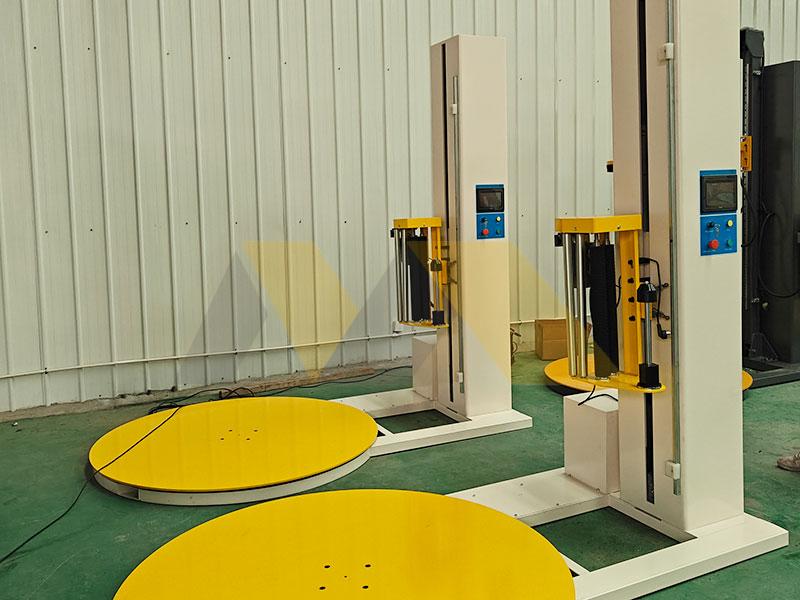

Semi-auto wrappers cut labor costs 40% while boosting wrap quality—ideal for medium-volume shippers needing automation’s speed without full robotic investment. They balance cost, efficiency, and ease of adoption.

These insights will transform how you handle pallet packaging. Let’s dive deeper.

Which businesses use semi-auto most?

A regional distributor near Shanghai doubled output after switching. Their workers embraced the turntable immediately—no more walking circles around pallets. Real relief for busy teams.

Logistics hubs, mid-sized manufacturers, and growing e-commerce warehouses adopt semi-automatics most—peak volumes of 100-300 daily pallets where hand-wrapping becomes a bottleneck but full automation remains overkill.

Industry adoption hotspots

Top user profiles

| Business Type | Daily Pallets | Pain Points Solved |

|---|---|---|

| Food Processing | 120-250 | Sanitary handling needs |

| Regional Warehouses | 150-400 | Mixed load types |

| Auto Parts Suppliers | 80-200 | Irregular shapes |

Why semi-auto fits best

- Budget alignment: 60% lower cost than full automation

- Space efficiency: Occupies 30% less floor space

- Staff adaptation: Operators master in under 2 days

Real case: A Ningbo exporter reduced wrap errors by 68% post-installation. Send your warehouse size via WhatsApp for custom recommendations.

How much time can it save?

Timed a worker wrapping manually: 8 minutes per pallet. Same worker with semi-auto: 2.5 minutes. Those minutes compound fast during peak seasons.

Operators achieve 2-3 pallets hourly gains through motorized rotation and preset tension—slashing average wrap cycles by 65% while improving load stability versus manual methods.

Efficiency metrics unpacked

Typical cycle time reductions

| Process Step | Manual (min) | Semi-Auto (min) | Savings |

|---|---|---|---|

| Film Application | 4.5 | 1.2 | 73% |

| Rotation Cycles | 2.0 | 0.3 | 85% |

| Securing Ends | 1.5 | 1.0 | 33% |

Output multipliers

- Throughput: 25-40 pallets/hour typical

- ROI drivers:

- Labor cost reduction ($2.80/pallet saved)

- Film waste decrease (15-25% less usage)

- Hidden benefits: Fewer worker injuries

One client reclaimed 120+ hours monthly—enough to delay hiring. Request our savings calculator today.

Are they easy to maintain?

Our simplest model needs just weekly wipe-downs. Compare that to robotic arms requiring specialist visits. Less downtime, more peace of mind.

With fewer moving parts than automatics, semi-autos deliver reliability via brush motor maintenance and universal belts—typically needing only 10 minutes weekly attention from operators.

Reliability architecture

Maintenance schedule

| Component | Care Frequency | Action | Criticality |

|---|---|---|---|

| Turntable Tracks | Monthly | Debris removal | ★★★☆☆ |

| Stretch Rollers | Quarterly | Bearing lubrication | ★★☆☆☆ |

| Control Panel | Biannual | Dust sealing check | ★☆☆☆☆ |

Failure-proof design features

- Sealed electronics: IP54 rating blocks dust invasion

- Modular components: Swap parts without tools

- Self-diagnostic alerts: Error codes display fixes

A Qingdao facility ran our units 3 years without breakdowns. WhatsApp our engineers for preventative checklist.

When to upgrade to fully automatic?

Client shipped 400 pallets daily—staff couldn’t keep up despite semi-autos. We upgraded them last spring. Their productivity jumped 120% overnight.

Scale up when exceeding 500 daily pallets consistently or when labor costs breach 30% of packaging expenses. Full automation delivers ROI at high volumes through unmanned operation.

Transition trigger framework

Upgrade indicators

| Metric | Semi-Auto Threshold | Auto Requirement |

|---|---|---|

| Daily Pallets | <400 | 500+ |

| Shifts/Day | 2 | 3+ |

| Labor Cost % | Under 25% | Over 30% |

Implementation strategy

- Hybrid staging: Run semi-autos alongside automatics

- Phased training: Staff learn PLC monitoring

- Throughput testing: Validate new system pre-cutover

Last month, we helped three clients transition smoothly. Get our upgrade roadmap—message anytime.

Conclusion

Semi-automatics boost SME productivity affordably. Maintain them easily and track key metrics. Upgrade when growth demands automation. Optimize your wrapping now.