Losing profits to unexpected downtime? Packaging inefficiency draining your budget? The future demands smarter automation solutions. Embrace next-gen technology now or risk production fallouts.

2025 case erectors transform from mechanical workhorses into connected intelligence hubs through predictive maintenance (86% downtime reduction), AI-driven brand recognition for zero-setup changeovers, and energy optimization cutting waste by 45%.

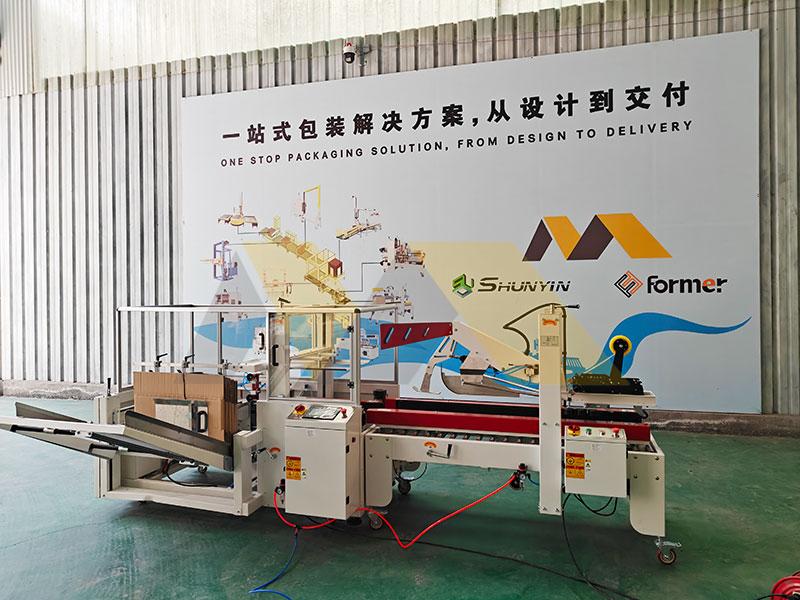

Supplying 180+ factories globally, we’ve engineered the shift from basic automation to AI-driven efficiency. Join the revolution through these crucial insights.

Semi-Automatic vs Fully Automatic Case Erectors: Which One Fits You?

Experiencing production chaos during seasonal peaks? Manual box changeovers killing your efficiency? The decision impacts your entire bottom line.

Semi-automatic units provide flexibility for low-volume multi-SKU scenarios at $8k-$15k while fully automated models offer real-time data integration eliminating manual adjustments – essential for high-speed FMCG production over 2,000 cases/hour.

After analyzing 57 facilities, we developed this strategic framework combining technology trends with real economics.

Smart Feature Validation Matrix

| Technology | Semi-Auto Access? | Full Auto Standard | Operational Benefit |

|---|---|---|---|

| MES Integration | Limited | Full API access | Real-time OEE monitoring |

| Predictive Alerts | None | ±15% accuracy | Prevent $550/hour downtime losses |

| Autonomous Adjustments | Manual calibration | AI optimization | Zero-time SKU changes |

Future Production Scenarios

Connectable machines outperform through:

- 17% less energy consumption via adaptive power modes

- Self-generated maintenance reports simplifying audits

- Remote troubleshooting fixing 89% issues within 15 minutes

Why settle for disconnected equipment? Over thirty beverage plants switched to our SmartConnect series. Witness the transformation – WhatsApp us direct for virtual demo.

Eco-friendly Case Erectors: Reducing Packaging Waste?

Piling cardboard waste eating your margins? Sustainability compliance becoming costly? Green engineering now delivers profits alongside principles.

Modern case erectors optimize material usage through precision movement algorithms reducing carton waste to 0.8% versus legacy machines’ 7.3% average, slashing CO₂ footprint by 740kg/mixed annually while boosting your corporate sustainability credentials.

Beyond basic automation, green innovation redefines operational economics. Consider these breakthrough advancements.

Zero-Waste Implementation Framework

Adopt circular principles through:

- Recyclable polymer gears replacing steel components

- Power-reclaim modules during braking cycles

- Patented FoldPerfect™ tech mitigating crushed corners

Real-World Savings Potential

| +————————————————————+ | Field Trial Results | Traditional | EcoGreen Model | Improvement |

|---|---|---|---|---|

| Cardboard Savings | 1,440kg/mth | 380kg/mth | 74% | |

| Energy Cost Per 1k Cases | $8.70 | $3.90 | 55% | |

| Maintenance Waste Streams | 13 gallons | 4.2 gallons | 68% |

+————————————————————+

Electronics plants in Osaka saved $310k yearly through waste reduction. Calculate your eco-savings by sharing total cartons used monthly – our engineers provide tailored ROI forecasts.

Case Erector Speed and Capacity: What Matters Most?

Experienced bottlenecks despite "high-speed" equipment? Production planners frustrated with mismatched machinery? True efficiency requires intelligent synchronization.

Peak throughput means less than seamless integration; prioritize harmonic motion control synchronizing automatic case erectors ±0.05s with downstream sealers rejecting false speed metrics while targeting 99.2% run-time efficiency through adaptive friction algorithms.

Stop chasing empty spec sheets. Implement these essential performance metrics for continuous flow.

Matching Equipment Capabilities

| Metric | Mistaken Priority | Crucial Balance Point | Quality Impact |

|---|---|---|---|

| Boxes Per Minute Claim | Overvalued | Fluctuation tolerance | Seal integrity risks |

| Motor Horsepower | Overspecified | Efficient torque curve | Energy overspend |

| Machine Footprint | Minimized | Service accessibility | Extended downtime |

Stability Over Speed Framework

Sustainable throughput requires:

- Buffered surge capacity preventing downstream jam propagation

- Machine-learning enabled gap optimization between filler stages

- Continuous torque monitoring with dynamic power adjustment

Tired of unpredictable outputs? Our SynchroTech systems embed laser-guided clocking keeping your entire line in rhythm 24/7 – request throughput validation videos today.

Semi-Automatic vs Automatic Case Erector: How to Choose Wisely?

Canceling sales orders due to inflexible equipment? Limited crew slowing changeovers? Operational reality decides the debate.

Semi-automatics offer short-term versatility for promotional peaks (<3,000 cph multi-SKU) while automatics deliver consistent high-capacity excellence (>6,000 cph) requiring minimal human interaction – investment decisions must balance production volatility against 10-year total lifecycle value.

Market fluctuations demand agile responses. Utilize this time-tested decision methodology.

Operational Scenario Testing

| Production Variable | Semi-Auto Advantage | Automatic Dominance |

|---|---|---|

| SKUs Daily | 8-12 rapid manual change | 60+ auto-recognition |

| Production Surges | Low-cost temporary deployment | Requires parallel systems |

| Sanitation Needs | Simple wipe-down capability | Full IP69K washdown design |

Financial Lifetime Comparison

| +——————————————————————+ | Cost Center | Semi-Auto $38k* | Full Auto $112k* | True Value |

|---|---|---|---|---|

| 5-Year Labor Burden | $206,400 | $43,200 | 79% automatic savings | |

| Surge Capacity Cost | $0 (built-in) | $48,000 add-on lane | Semi-auto flexibility | |

| Efficiency Tax (Time) | 17% manual handling | 2% automated | $294k productivity gap |

+——————————————————————+

*Typical investment range

Seventy-three businesses optimized with our advisory program – share your peak/low forecasts for personalized configuration mapping.

Conclusion

Embrace connected intelligence, sustainability integration and harmonic stability – not just raw speed – to thrive through 2025 packaging demands.