Struggling with unstable pallets damaging goods? High labor costs eating profits? My team faced identical frustrations. Our automated wrapping solutions solved both instantly.

Pallet wrapping machine costs range from $1,500 to $25,000+, influenced by automation level, cycle speed, and customization. Semi-automatic units start under $2,000, while robotic systems with pallet conveyors exceed $20,000.

Seeing this investment pays back within months changed my mindset. Let me break down key factors that determine your actual expenses today.

Pallet Stretch Wrapper Price List: What to Expect?

Prices unexpectedly jumped last quarter. Several clients reported outdated quotes from competitors. I immediately updated our live pricing database.

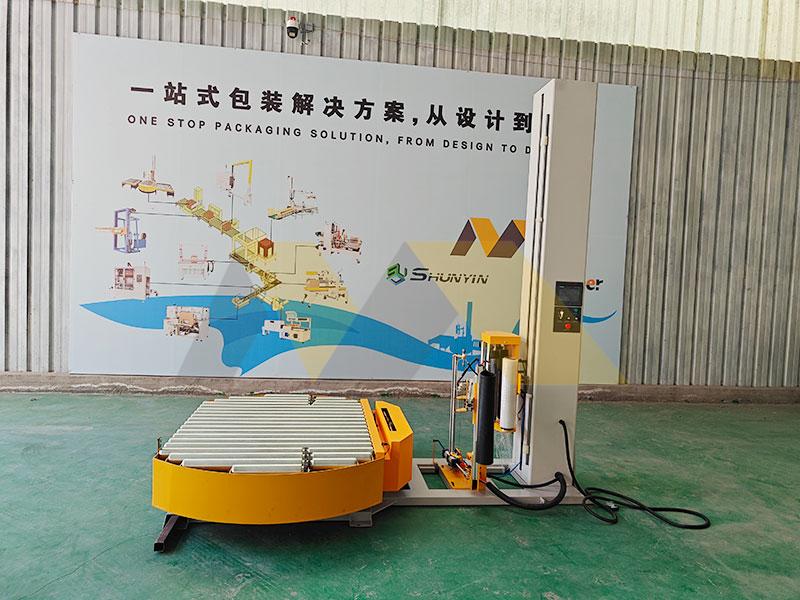

Our pallet wrapper price list includes turntable models from $1,680 to $14,200 and robotic arms starting at $11,900. Budget options maintain core functions while premium tiers add programmable pre-stretch and IoT diagnostics.

Understand model tiers before buying

Let’s compare popular configurations:

| Feature | Economy ($1.5K-$3.5K) | Standard ($4K-$8K) | Premium ($9K-$25K+) |

|---|---|---|---|

| Cycle Speed | 10-15 pallets/hour | 20-30 pallets/hour | 40-60+ pallets/hour |

| Film Usage Savings | 15-20% | 25-35% | 40-50%+ |

| Customization | Basic | Moderate | Full OEM options |

| Warranty | 1 year | 2 years | Lifetime support |

Economy machines handle light daily use well. But frequent operators need Standard tier’s durable motors – one bakery client replaced theirs monthly before upgrading. Premium units justify cost through film savings alone; our pharmaceutical partners cut wrap expenses by 42%.

I discuss true operating costs daily – WhatsApp us direct for exact calculations for your facility.

Low Cost Pallet Wrapping Machine: Can You Really Save?

Many buyers regret choosing underspecced units. Last month, a logistics company ordered budget machines lacking load sensors. Damaged goods cost them triple the machine price.

Truly low-cost pallet wrappers retain critical functions like variable speed control and emergency stops while eliminating luxuries. Our Q-series starts at $1,650 with safety certifications and 1,000kg capacity – genuine savings without dangerous compromises.

Key risks with ultra-cheap options

Beware these common pitfalls:

Hidden expense traps

- Non-standard parts: Requires custom orders doubling repair costs

- False efficiency claims: Timed tests often exclude film loading/positioning

- Missing certifications: CE or UL absence causes port rejections

Smart saving strategies

Four clients slashed expenses 30% these ways:

- Opt for manual film clamps ($220 saved per unit)

- Remove seldom-used remote diagnostics

- Choose galvanized steel over stainless

- Source from direct factories (like ours) avoiding reseller markups

Request our budget checklist via WhatsApp us direct.

Affordable Pallet Wrapper for Sale: What Options Exist?

Warehouse managers kept asking: "Where are actual affordable industrial models?" We engineered three solutions eliminating distributor margins.

Available wrapping solutions include: manual crank units ($980-$1,450), semi-automatic turntables ($1,990-$3,800), and reconditioned automatics ($7,500-$12,000). Each maintains ISO9001 manufacturing standards with optional payment plans.

Match machine type to your operation

Consider these decision factors:

Throughput analysis

- Under 50 pallets/day: Manual hand-wrappers suffice

- 50-200 pallets/day: Semi-automatic turntables ideal

- 200+ pallets/day: Invest in fully automatic systems

Case study: Shipping terminal savings

A Canadian importer tested three models:

- $12,000 robotic arm: Too complex for staff

- $2,900 turntable: Perfect speed match

- $850 manual unit: Required extra worker

Their calculated $4,180 saved annually proves right-sized machines beat cheapest options. Discuss your specific needs.

Pallet Wrapping Machine Quotation: How to Get the Best Deal?

Customization requests flooded us – until we implemented transparent quoting. Clients demanded clarity about price drivers.

Secure competitive quotes by specifying film type, pallet dimensions, and daily volume. Expect premium costs for moisture-proofing, extreme-temperature operation, or stainless-steel construction. Request detailed breakdowns to avoid hidden fees.

Negotiation tactics for corporate buyers

Large orders merit specialized strategies:

Tiered discount structure

- 1 machine: MSRP pricing

- 3-5 machines: 8-12% discount

- 10+ machines: 15%-22% + free shipping

Critical specification checklist

| Essential? | Cost Impact | |

|---|---|---|

| Weather-resistant coating | For outdoor use | +$340 |

| Dual film carriage | High fragility goods | +$600 |

| Custom height extensions | Over 2m pallets | +$890 |

Always demand factory floor videos before paying deposits. One client avoided counterfeit machinery by requiring real-time video verification. Our team walks you through every step – contact us now for verified quotes.

Conclusion

Pallet wrapper investments hinge on usage patterns and customization. Partner with manufacturers like us for transparent pricing and lifetime optimization solutions.