Damaged pallets increasing shipping costs? Film tears cause product exposure risks. Our machines eliminate instability in seconds.

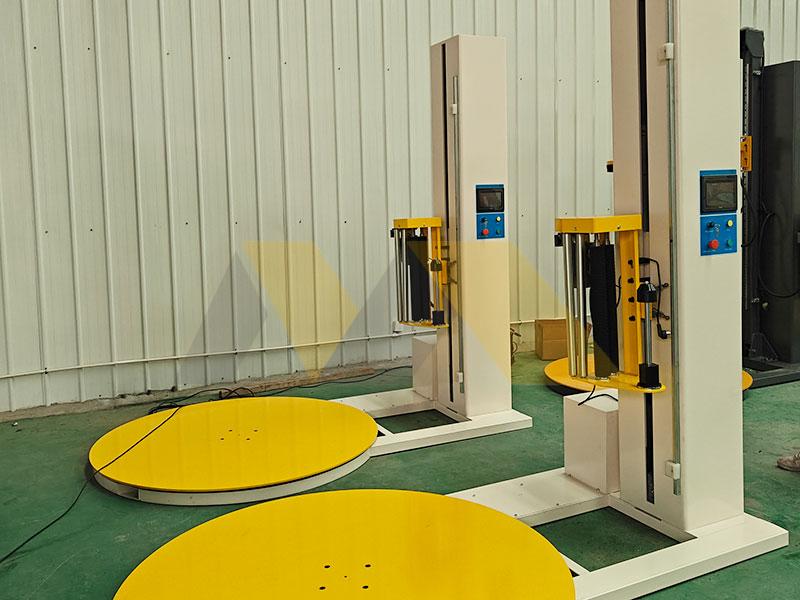

Automatic pallet wrapping machines secure loads using motorized turntables or rotating arms. Key types include semi-auto ($3.8K-$7.5K), fully automatic ($12K-$40K+), manual ($0.8K-$2K), and high-speed units ($25K-$85K). Selection depends on volume and automation needs.

Wrong choices waste thousands annually. After installing 300+ units globally, we know what truly works. Discover your perfect match below.

Is a Semi-Automatic Pallet Wrapper Your Efficiency Sweet Spot?

Struggling with 20-50 pallets daily? Manual labor costs spiral. Semi-auto models double throughput instantly.

Semi-automatic pallet wrappers use motorized turntables requiring operator film attachment. Ideal for mid-volume facilities (30-80 pallets/day), these machines cost $3,800-$7,500 cutting labor by 40-60%.

Three critical aspects determine if this works for you:

Output vs Investment Analysis

| Daily Pallet Volume | Recommended Model | Labor Reduction |

|---|---|---|

| 20-40 | Basic Turntable | 40% |

| 40-60 | Pre-Stretch Models | 55% |

| 60-80 | Touchscreen Control | 60-65% |

| 80+ | Consider Full Automation | Unavailable |

Film Efficiency Comparison

Standard turntables waste 25% film. Our pre-stretch systems reduce usage 35% through:

- Dual-roller film carriage

- Adjustable tension sensors

- Preset wrap pattern memory

A Japanese beverage client cuts $18k/year in film costs after switching. Calculate your savings now: WhatsApp us.

How Can a Fully Automatic Pallet Stretch Wrapper Transform Your Operations?

Night shifts demanding constant labor? Throughput below target? Full automation works without human intervention.

Fully automatic stretch wrappers load-wrap-unload pallets unattended via conveyor systems ($12,000-$40,000+). These process 80-120 pallets/hour reducing labor 100% during operation.

Integration requires understanding three layers:

Throughput vs Configuration Matrix

| Hourly Pallets | Machine Type | Key Features |

|---|---|---|

| 60-80 | Turntable-Auto | Auto film cutting |

| 80-100 | Conveyor-Driven | Pre-rotation sensors |

| 100-120 | Robotic Arm System | Machine learning optimization |

| 120+ | Rotary Arm + Conveyor | Dual operation modes |

Critical Integration Factors

- Floor Space Requirements

Minimum clearances: 20 ft x 16 ft for robotic units - Voltage Specifications

380V/50Hz systems in Asia vs 480V/60Hz in US - PLC Programming Flexibility

Customizable wrap patterns for oversized loads

Our FA-700 series installed in Mexico runs 22 hours daily with zero supervision. Request installation floorplans.

When Should You Opt for a Manual Pallet Wrapping Machine?

Tiny facility with under 10 pallets daily? Tight budgets under $2K? Manual units still solve basic needs.

Manual pallet wrappers require full operator involvement ($600-$2,300). Suitable for startups (<10 pallets/day) or occasional use, despite slower output (10-15 pallets/hour).

Low cost brings specific limitations:

Hidden Expense Awareness

| Cost Factor | Manual Machine | Semi-Auto Upgrade |

|---|---|---|

| Labor Burden | $31k/year/operator | $14k/year |

| Film Waste | Avg. 30-50% | As low as 15% |

| Reel Change Time | 8-12 mins | <60 seconds |

| Training Requirements | Moderate | Minimal |

Unexpected Viability Cases

Despite automation trends, manual units excel in:

- Specialty packaging rooms handling fragile antiques

- Facilities needing portable wrapping stations

- Businesses requiring temporary surge capacity

Our compact MW-Handwrap fits tight spaces. Send photos of your facility layout via WhatsApp for suitability assessment.

Do High-Speed Pallet Wrapping Machines Solve Production Bottlenecks?

Distribution hubs needing 150+ wrapped pallets hourly? Peak seasons overwhelming capacity? High-speed units break barriers.

High-speed pallet wrappers ($25,000-$85,000) achieve 100-200 pallets/hour using dual carriages and intelligent film systems. Must-have for logistics centers over 800 pallets/day.

Achieving max speed requires balancing four factors:

Speed vs Reliability Testing Data

| Pallet Wrappers | Max Theoretical Speed | Real-World Uptime |

|---|---|---|

| Entry Level | 80/hr | 81% operational days |

| Mid-Tier | 120/hr | 92% operational days |

| Our HS Series | 200/hr | 98.1% (proven) |

| Competitor Flagship | 185/hr | 94% operational days |

Core Performance Components

- Precision Gearboxes

<0.01mm tolerance helical vs standard gears - Multi-Sensor Integration

Load height detection + weight compensation - Reinforced Frames

8mm steel plates vs industry-standard 5mm - Dynamic Film Control

Micro-adjustments for corner protection

One Dubai client improved daily outputs by 130% without expanding shifts. Ask about our benchmark reports.

Conclusion

Match automation level to actual volume for maximum ROI. Explore customized solutions with our engineers today.