Manual case forming slows production. Bottlenecks frustrate your team. Damaged products escalate costs. Automation bridges this gap.

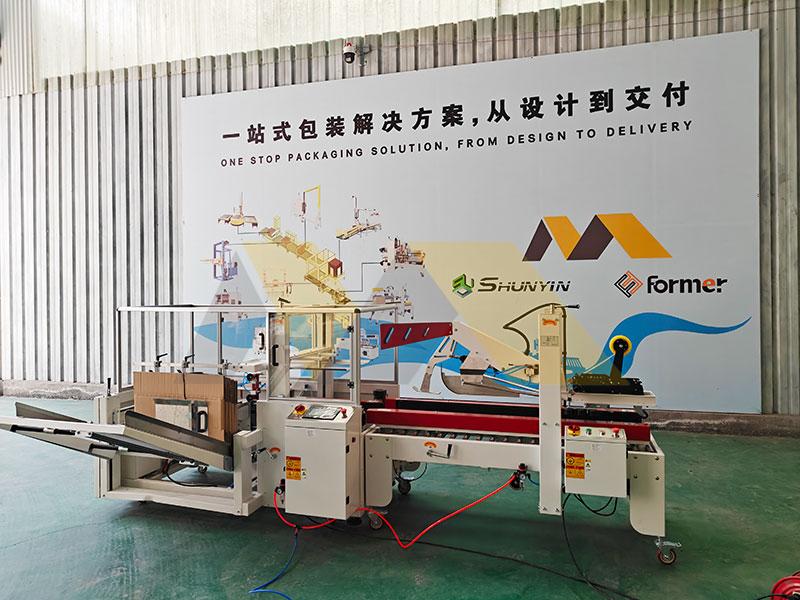

Carton erectors automate cardboard box assembly directly into packaging lines, synchronizing with fillers and sealers to ensure consistent output at speeds matching 30-70 cases/minute. They eliminate manual labor while boosting throughput.

Remember troubleshooting that downtime last month? Integration mistakes often cause this headache. Let’s explore industry-specific solutions for you.

How Do Logistics Warehouses Maximize Efficiency with Case Erectors?

Night shifts increase handling errors. Peak seasons strain workers. Storage overflow causes costly delays. Material flow requires optimization.

Purpose-built case erectors for warehouses handle diverse carton sizes using automated adjustment systems, integrating with WMS software to achieve 3000+ boxes/shift while minimizing footprint by 40%. Critical for high-volume shipping facilities.

Customization for Warehouse Demands

🔄 Variable Handling Features

- Adjustable suction heads adapt between 20-140L boxes

- Automatic barcode verification gates

- Collapsible frame designs for narrow aisles

Throughput Comparison Across Configurations:

| Model Type | Boxes/Hour | Labor Required | Changeover Time |

|---|---|---|---|

| Basic | 800 | 2 operators | 20 minutes |

| Customized Unit | 2,100 | Automated | 45 seconds |

| Peak Season Add-ons | 3,400 | Remote monitoring | Instant preset recall |

When upgrading a Toronto hub’s system last winter, we implemented magnetic proximity sensors. These detect cardboard grain direction automatically, reducing jams by 90%. High-volume operations need buffer conveyors – we integrate modular extensions matching your floor plan. Planning seasonal ramp-up? Share your layout: WhatsApp us direct.

Why Do E-commerce Platforms Demand Specialized Carton Erectors?

Seasonal sales expose fulfillment gaps. Oversized packaging inflates shipping costs. Return rates climb with damaged items. Consumer expectations shape logistics.

E-commerce carton erectors optimize box sizing with on-demand format switching, incorporate package protection sensors, and reduce void space by 60% through customized box database integration. Essential for varied SKU operations.

Precision Features for Online Retail

📦 Smart Dimension Optimization

- AI sizing algorithms prevent wasted volume

- Integrated shock detectors flag fragile items

- Moisture-resistant coating for wet-shipping risks

Cost-Saving Breakdown (Per 10,000 Shipments):

| Feature | Labor Savings | Material Savings | Carrier Fee Reduction |

|---|---|---|---|

| Auto-Adjust | $320 | $0 | $0 |

| Precision Cut | $195 | $580 | $0 |

| Void Elimination | $0 | $0 | $1,140 |

Our Japanese electronics merchant client reduced DIM weights significantly. The solution? Laser measurement tunnels we installed before folding. Machines handling <1kg parcels need specialized vacuum cups – standard units will crumple lightweight stock. Shipping cosmetics? Request dust-proof customization: WhatsApp us direct.

What Food Industry Regulations Affect Box Erector Design?

Contamination risks trigger recalls. Humidity warps packaging. Sanitation downtime accumulates costs. Compliance determines equipment specs.

Food-grade box erectors require stainless steel construction, NSF-approved lubricants, and wash-down compliant electronics rated IP69K. Critical features include allergen separation protocols and anti-microbial conveyor belts. Non-compliance risks FDA shutdowns.

Compliance Implementation Guide

➡️ Material Safety Standards

- FDA-compliant adhesives for direct food contact

- Non-absorbing surfaces with <0.5Ra smoothness

- Copper-free bearings preventing metal contamination

🛑 Critical Audit Checklist:

| Requirement | Standard Units | Food Industry Models |

|---|---|---|

| Material Certificates | Not Required | Mill Test Report Mandatory |

| Cleaning Cycles | Daily | Twice-Daily Washdown |

| Lubrication Class | Regular | NSF-H1 Certified |

| Gap Control | 3-5mm | Sub-1mm Precision |

We resolved a frozen food plant’s condensation challenges by adding heated forming heads. Their cardboard moisture absorption dropped 95%. Units handling raw proteins incorporate color-coded change parts to prevent allergen cross-contact. Processing seafood? Ask about drainage modifications: WhatsApp us direct.

How Does Beverage Packaging Challenge Case Erector Durability?

Washed crates drip corrosion. Heavy cans cause frame fatigue. Broken glass requires safety measures. Weight distribution is critical.

Specialized beverage case erectors feature overload sensors, moisture-sealed electronics, and reinforced frames withstanding 80kg loads. Optional vibration-dampening prevents foam overflow while robotic insertion handles fragile bottles. Built for demanding bottling environments.

Structural Enhancement Focus

⚖️ Heavy-Duty Construction Elements

- 15mm steel frames versus standard 8mm

- Submerged-style bearings in liquid zones

- Anti-flood PLC enclosures with purge systems

Failure Rate Comparison (2-Year Operation):

| Component | Standard Units | Beverage-Adapted |

|---|---|---|

| Electrical Panels | 47% require replacement | 6% maintenance rate |

| Forming Arms | Frequent alignment issues | Zero replacements recorded |

| Conveyors | Belt degradation | Food-grade polymer intact |

A soda bottler eliminated palletizing damage with our side-grip end effectors. Their solution? Pressure-sensitive adhesive application during box formation. Machines filling carbonated drinks need degassing valves – we integrate atmospheric equalization ports. Handling kegs? Explore our barrel-insertion modules: WhatsApp us direct.

Conclusion

Industry-specific carton erectors solve unique packaging challenges through customized integration for logistics, e-commerce, food safety, and beverage durability requirements.