Manual box assembly wastes resources. Production delays frustrate teams. Damaged goods shrink profits. Discover automation’s power.

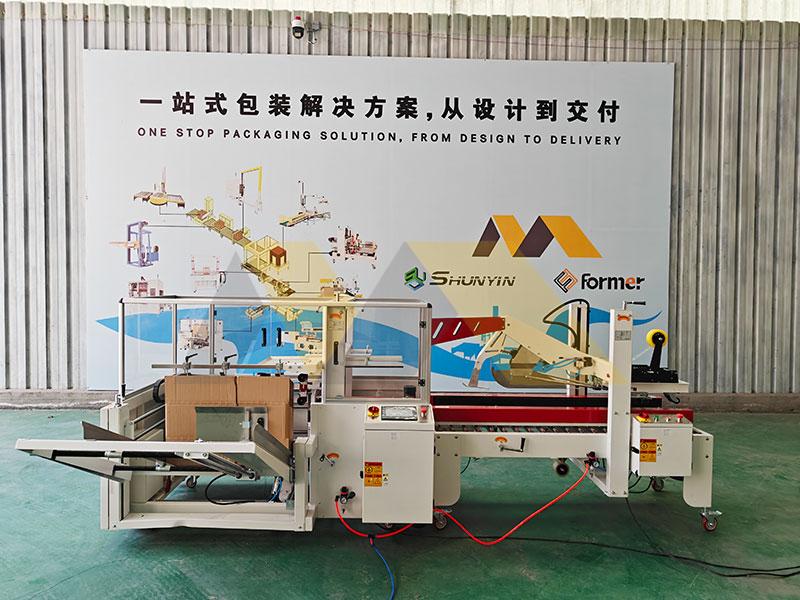

Automatic carton erector machines form cardboard blanks into ready boxes at 15-65 cases per minute. Essential for high-volume industries, these units enhance throughput while reducing labor costs and material waste. Manufacturers like us offer custom-engineered solutions.

Consider how these machines revolutionized a cosmetics factory last quarter. Their results may surprise you. Let’s unpack key specifications before deciding.

What Defines a Truly High-Speed Case Erector?

Slow outputs frustrate managers. Production gaps increase overtime expenses. Subpar machines limit growth potential. Your throughput requires precision engineering.

True high-speed case erectors achieve 45-65 cases/minute through integrated servos, automated glue systems, and advanced transfer conveyors. Robust models include predictive maintenance sensors to prevent unexpected downtime. Quality units maintain accuracy at peak speeds.

Critical Components for Reliability

🚀 Motion Control Systems

Digital servo motors outperform traditional hydraulics:

- Energy savings up to 60%

- ±0.3mm positioning accuracy

- Adaptive speed compensation

🛡️ Structural Integrity Features

Our North American clients frequently request these reinforcements:

| Component | Standard Units | High-Speed Models |

|---|---|---|

| Frame | 8mm carbon steel | 12mm reinforced alloy |

| Bearings | Standard grade | ABEC-7 precision |

| Vibration dampeners | Rubber mounts | Active pneumatic isolators |

A food processing plant hit 62 CPM after we upgraded their transmission shafts. The key? Avoiding harmonic resonance through asymmetric gearing design. For sustained outputs above 50 CPM, forced-air cooling prevents overheating – we install thermocouples at critical points. Challenged by speed limitations? Send your requirements: WhatsApp us direct.

Why Consider Semi-Automatic Carton Erectors Today?

Total automation isn’t always feasible. Labor optimization remains critical. Budget limitations demand smart compromises. Flexibility creates advantages.

Semi-automatic carton erectors boost output 3x versus manual folding with just one operator. Priced at 30-40% less than full automation, they suit limited production runs where quick format changes occur frequently. Ideal for plants with under 30 daily pallet loads.

Operational Optimization Guide

🔧 Hybrid Workflow Setup

- Human feeds blanks into conveyor system

- Machine precision-folds four flaps simultaneously

- Operative seals boxes during continuous flow

Investment Recovery Matrix

| Production Scale | Payback Period | Format Change Time |

|---|---|---|

| < 5K boxes/day | 6 months | 8 minutes |

| 5-15K boxes/day | 4 months | 12 minutes |

| > 15K boxes/day | 9 months | Not recommended |

Our Japanese electronics client kept their existing team while doubling output. We retrofitted air-assisted ergonomic lifts that reduced operator strain by 70%. Semi-auto shines when handling irregular box sizes – manual correction beats machine jams. Considering your product variation? Share your box catalog: WhatsApp us direct.

How Does Efficient Carton Box Erector Design Impact ROI?

Energy waste inflates expenses. Maintenance hours disrupt schedules. Poor integration requires costly modifications. Intelligent engineering pays dividends.

Efficient erectors deliver optimized case forming through precision-synchronized arms, minimal air consumption valves, and quick-change tooling. Advanced PLCs reduce energy usage 40% versus legacy models while increasing MTBF metrics.

Efficiency Enhancement Features

⚡ Smart Power Management

- Auto-sleep during gaps in production

- Energy feedback regeneration systems

- LED lighting replacing fluorescents

📊 Operational Efficiency Analysis

| Metric | Basic Unit | High-Efficiency Model |

|---|---|---|

| kWh/1000 boxes | 12.8 | 7.2 |

| Daily air consumption | 18 m³ | 5 m³ |

| Format change time | 25 min | 6 min |

A Canadian supplier eliminated compressor upgrades when we redesigned their pneumatic circuit. Dual vacuum generators running pulse-width modulation cut air demand by 65%. Lubrication-free bushings last 5 years—no messy oil leaks contaminating packaging. Upgrading existing equipment? Request efficiency audit: WhatsApp us direct.

When Does Carton Erector with Hot Melt Glue Outperform Tape?

Carton pop-ups cause product damage. Stuck cases jam conveyors. Humidity-reactivated adhesives fail during shipping. Seal integrity demands science.

Hot melt glue erectors create tamper-evident bonds instantly at temperatures from 155-185°C. They prevent reopening during transit and tolerate extreme environments where tapes would fail. Perfect for cosmetic, electronics, and pharmaceutical boxes.

Application Decision Matrix

🧪 Adhesive Selection Guide

| Box Use Case | Recommended Glue Type | Setting Time |

|---|---|---|

| Cold storage | Low-temp formula (155°C) | 1.3 sec |

| High-value goods | Tamper-evident polymer | 1.1 sec |

| Heavy products | Cross-linked adhesive | 0.9 sec |

We helped a Singapore lab eliminate cold chain failures with temperature-adjustable nozzles. Glue patterns are crucial – spiral dots work better than beads on porous cardboard. Our proprietary anti-charring nozzles outlast competitors by 300%. Still deciding the right adhesive? Get free sample applications: WhatsApp us direct.

Conclusion

Select carton erectors based on throughput needs, while evaluating speed options, automation level, energy efficiency, and bonding methods to maximize production gains.