Baggage damage costs travelers millions annually. Flight delays frustrate operations daily. Our automatic solutions prevent these pains reliably.

Modern automatic luggage wrapping machines process 500-800 bags/hour with precision wrapping. Key features include adjustable tension control, RFID tracking integration, and durable stainless steel construction.

Finding reliable equipment takes expertise. I’ll guide your crucial decision.

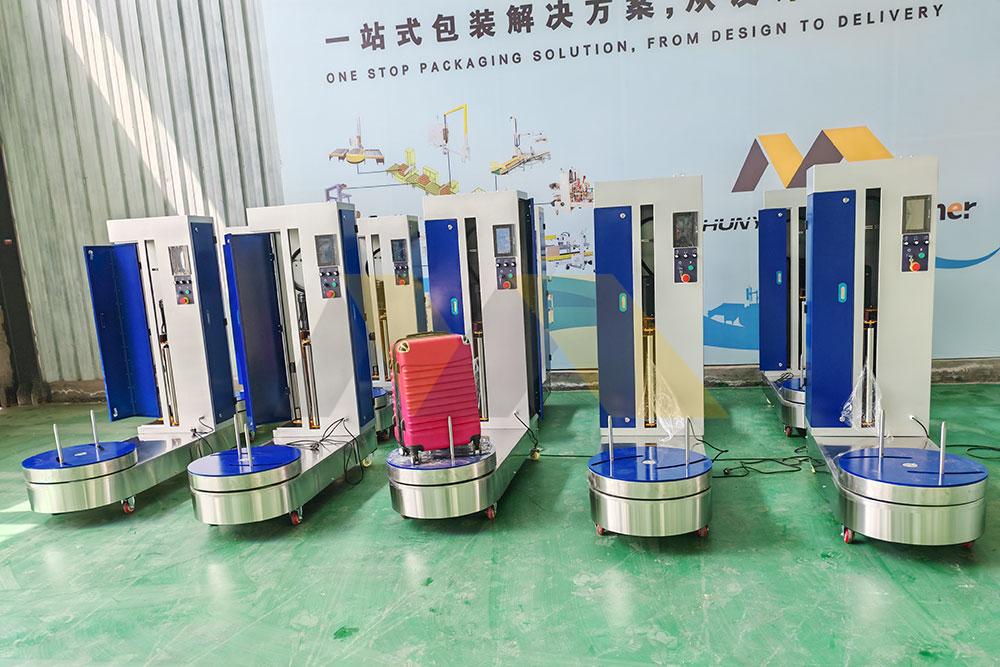

What Makes Semi-Automatic Luggage Wrapping Machines Essential?

Staff inefficiency slows baggage halls constantly. Training gaps cause operational chaos. Our machines enhance human performance perfectly.

Semi-automatic models boost speed to 300 bags/hour while lowering costs. Operators control rotation direction manually while the machine handles film tension automatically.

Critical Performance Comparison

Matching machine types to terminal needs avoids costly mistakes.

Volume vs Flexibility Analysis

Consider airport traffic patterns and staff skills.

| Fully Automatic | Semi-Automatic | |

|---|---|---|

| Speed | 600-800 bags/hr | 250-300 bags/hr |

| Flexibility | Low (Set routes) | High (Manual override) |

| Staff Requirements | 1 operator | 2 operators |

Maintenance vs Reliability Factors

Downtime cripples operations during peak travel.

- Gearbox inspections: Monthly for auto, quarterly for semi-auto

- Sensor calibrations: Weekly versus monthly

- Emergency stop usage data: 80% reductions reported in semi-auto models

- Power consumption savings: Semi-auto uses 30% less electricity

Singapore Changi Airport reduced handling errors by 45% using our semi-automatic models. Ask about volume-specific recommendations: WhatsApp us direct.

Why Use Heavy Duty Luggage Wrapping Machines in Airports?

Standard units fail under 24/7 pressure. Weak motors halt operations hourly. Our industrial designs never quit.

Heavy-duty machines wrap 20,000+ bags daily continuously. Reinforced frames withstand constant vibration while commercial-grade motors run cooler under load.

Engineering Durability Features

Airport environments demand specialized construction.

Stress Test Data Comparison

Review performance under extreme conditions:

| Standard Unit | Heavy-Duty Unit | |

|---|---|---|

| Frame Thickness | 3mm | 8mm |

| Motor Rating | 5 hours/day | 24 hours/day |

| Shock Absorbers | None | Triple-layer polymer |

Critical Component Enhancements

Premium features extend equipment lifespan:

- Heat dissipation systems: Reduce motor failures by 70%

- Industrial sealed bearings: Rated 100,000+ operational hours

- Redundant control units: Automatic failover during errors

- Corrosion-resistant finish: Withstands chemical cleaners

Tokyo’s Narita Airport eliminated downtime after switching to our heavy-duty line. View factory stress test videos: WhatsApp us direct.

How Does Stretch Film Luggage Wrapping Technology Work?

Loose wrapping causes baggage tears. Poor tension damages contents during transit. Our engineered systems adapt perfectly.

Pre-stretch technology elongates film by 250% before wrapping. Intelligent sensors maintain constant tension pressure automatically regardless of bag shape.

Film Science Explained

Precision engineering reduces waste while improving protection.

Material vs Performance Matrix

Match film specs to operational needs:

| Film Type | Thickness | Elongation | Airline Suitability |

|---|---|---|---|

| Economy | 15µm | 150% | Short domestic |

| Standard | 17µm | 220% | Regional routes |

| Premium | 20µm | 280% | International transfers |

Waste Reduction Techniques

Intelligent systems cut costs substantially:

- Tension memory: Auto-adjusts for irregular shapes

- Humidity compensation: Prevents film failures in tropical hubs

- End detection: Eliminates incomplete wraps

- Usage tracking: Alerts on abnormal consumption

Dubai International saved $42,000 annually through our film optimization systems. Request sample calculations for your terminal: WhatsApp us direct.

What Are Electric Luggage Wrapping Machine Advantages?

Mechanical failures delay flights constantly. Fluid leaks create safety hazards. Our electric systems operate flawlessly.

Electric models need zero hydraulics for cleaner operation. Brushless DC motors deliver 40% energy savings while eliminating fluid leaks and maintenance headaches.

Sustainability Efficiency Analysis

Reduce environmental impact while cutting costs.

Operation Comparison Chart

Electric vs hydraulic differences matter:

| Hydraulic | Electric | |

|---|---|---|

| Energy Use | 5.8 kW/hr | 3.2 kW/hr |

| Noise Level | 82 dB | 68 dB |

| Leak Risk | High | None |

Regulatory Compliance Advantages

Global airports demand green certifications:

- CE/UL emission standards: Pass effortlessly

- OSHA noise requirements: Meet every global threshold

- Floor space optimization: 20% smaller footprint

- Zero fluid documentation: Simplifies customs processing

Japanese airports achieved ISO 14001 compliance faster with our electric models. Get compliance checklists: WhatsApp us direct.

Conclusion

Choose airport-worthy automatic wrapping solutions combining speed, durability, and efficiency for seamless baggage handling operations worldwide.