Struggling with contamination risks? Manual box handling spreads bacteria. Our food-grade machines solve this with hygienic designs.

As specialists in food packaging case erectors, I build stainless steel machines that pass FDA audits. Each unit includes allergen protocols – WhatsApp us to discuss your sanitization needs today.

Cross-contamination costs clients. Now explore sector-specific solutions.

Case Erector for Beverage Carton Boxes?

Moisture ruining packaging? Wet beverage boxes jam standard machines. We’ve engineered specialized solutions.

Beverage case erctors feature humidity-resistant materials and drainage systems. Myway models handle condensation-heavy environments at 25 boxes/minute – message us for condensation test videos.

Critical Design Features for Liquids

Moisture Management System

-

Corrosion Protection

- 316L stainless steel construction (+$2,100 cost)

- Halves replacement frequency vs carbon steel

-

Anti-Jam Technology Problem Standard Machine Our Solution Wet flaps Stops production Vacuum-assisted folding Soaked glue Smears Immediate drying nozzles Wet labels Slippage Micro-suction cups

Speed-Adjustment Protocol

- Slows 40% during high humidity

- Automatic pressure calibration when handling bottles

- Self-cleaning rollers during shift changes

Last client saved $28,000/year after switching – their previous machine jammed daily. Share your hourly bottle count for our humidity-response calculator.

Carton Case Erector for Pharmaceutical Packaging?

Validation paperwork overwhelming? Non-compliant machines halt production. We solve regulatory challenges.

Pharmaceutical erectors include full traceability logs and GMP certification. My units maintain Class 8 cleanroom standards – request our documentation package now.

Meeting Medical Industry Demands

Compliance Essentials Checklist

- Material Certificates (USP Class VI plastics)

- Particle emission reports (<100 particles per ft³)

- Calibration records per FDA 21 CFR Part 11

Contamination Control Features

| Feature | Importance | Cost Impact |

|---|---|---|

| Sealed bearings | Blocks lubricant leaks | +$800 |

| Antibacterial coatings | Prevents biofilm growth | +$450 |

| Positive air pressure | Stops contamination entry | +$1,100 |

Operational Validation Support

We provide:

- IQ/OQ documentation templates

- 3rd-party validation services

- Audit preparation specialists

One North American client passed surprise EU inspection after implementing our protocol. Need compliance help? WhatsApp our validation team immediately.

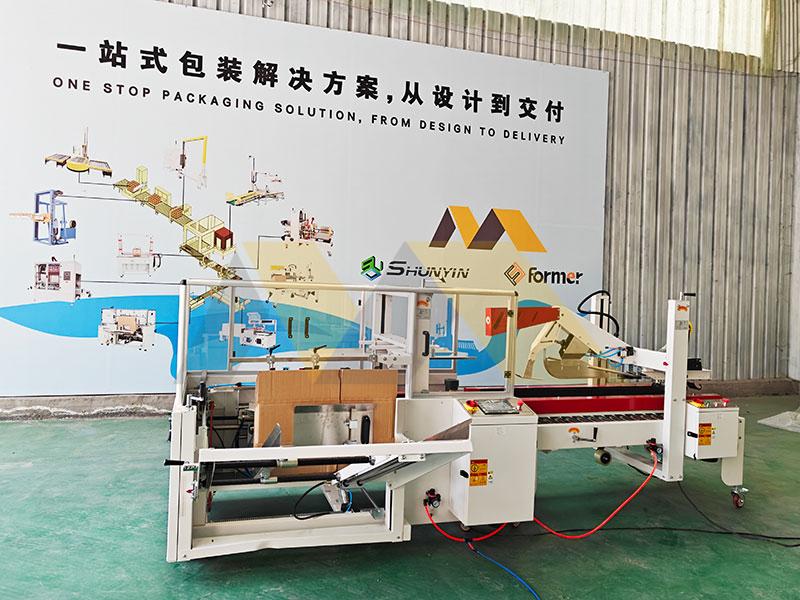

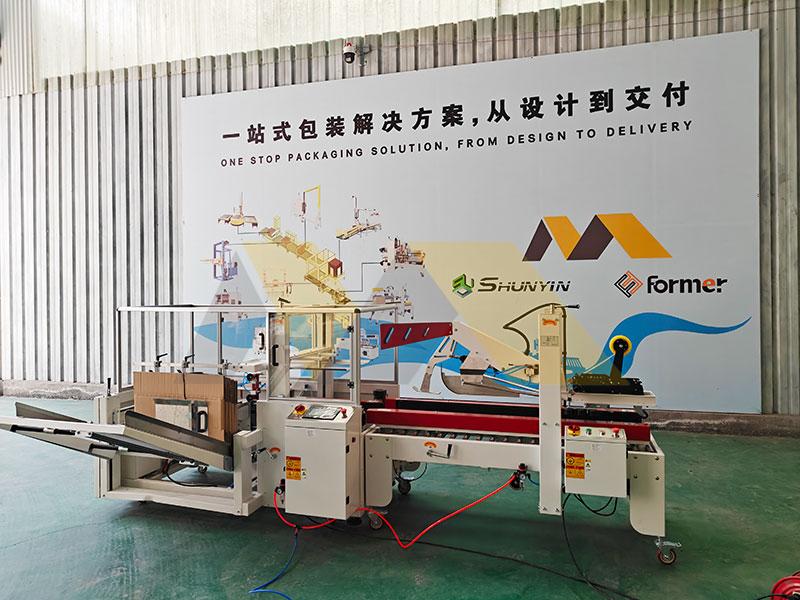

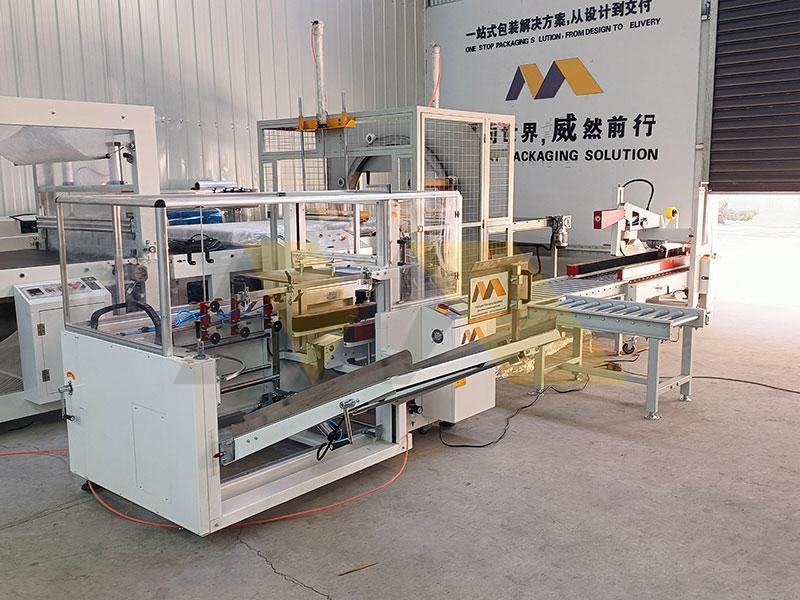

Case Erecting Machine for Factory Production Line?

Production gaps costing thousands? Machine integration failures create bottlenecks. We ensure seamless operation.

Factory production line erctors sync with existing systems via IoT. I customize each machine to fit your workflow – send your layout plans for integration analysis.

Maximizing Line Efficiency

Throughput Optimization Matrix

| Bottleneck | Solution | Impact |

|---|---|---|

| Changeover delays | Quick-release tooling | 85% faster format change |

| Speed mismatches | Variable frequency drives | Balance line speeds |

| Error accumulation | Automatic rejection ports | Reduce rework waste |

Predictive Maintenance Advantages

- Vibration sensors detect imbalance 48 hours before failure

- Remote diagnostics allow overseas fixes

- Customized spare parts kits included

Japanese factories achieve 99.2% OEE with our units. How many shifts do you run daily? We’ll configure the optimal solution.

Case Erector for Warehouse Automation?

Labor shortages disrupting warehouse flow? Manual box erecting causes delays. We automate the entire process.

Warehouse erectors integrate with WMS systems and work 24/7. Myway models reduce labor dependence by 90% – test operation through our live facility camera.

Full Warehouse Integration Framework

| Stage | Requirement | Our Feature |

|---|---|---|

| Box Retrieval | Automated opening | Sensor-enabled flap detection |

| Erecting | Unattended operation | Self-monitoring torque control |

| Loading | Position precision | Laser-guided placement |

| Tracking | Inventory sync | API-based WMS integration |

Implementation Roadmap

- Pre-installation

- Pallet pattern mapping

- Loading zone optimization

- Installation

- One-day setup guarantees

- Operation

- Remote operational training

Canadian warehouses save $6,600 monthly per machine. Contact us via WhatsApp to calculate your specific savings.

Conclusion

Specialized case erectors solve critical packaging problems. I deliver compliant solutions – message our engineering team with your challenge.