Damaged goods during transit cost businesses millions yearly. Securing loads properly reduces these losses drastically. As a factory owner, I see how our machines prevent this daily.

Top Chinese pallet wrapping machine manufacturers like Myway offer unmatched value with ISO-certified production, 30% lower costs than Western brands, and complete customization from our Guangzhou facility. We ship 500+ units monthly to Canada and US buyers. Connect directly: WhatsApp us.

Still assessing options? Many buyers misunderstand Chinese manufacturing. Having worked with 120+ North American distributors, I’ll break down critical factors.

How to Maximize Profits with Pallet Wrapping Equipment Wholesale?

Wholesale purchases often bring inventory headaches. Storage costs and slow turnover drain budgets. Our approach solves this.

Strategic pallet wrapping equipment wholesale requires MOQs of 5+ units with staggered shipments. We offer bonded warehousing and JIT delivery coordination to slash carrying costs 40%. Volume discounts reach 15% for 20+ machines.

Optimizing Your Wholesale Procurement Plan

Logistics Cost Comparison Table

| ^^^shipping-options | Method | Cost/Unit | Lead Time | Ideal For |

|---|---|---|---|---|

| FCL Shipment | $320 | 30 days | Established dealers | |

| LCL Consolidation | $550 | 45 days | New market entries | |

| Air Freight | $2,100 | 7 days | Emergency replacements |

^^^

Inventory Management Techniques

We implement these with wholesalers:

- Demand forecasting using seasonal sales data

- Pre-production alerts 60 days before peak seasons

- Kitting services to bundle spare parts

Last November, a Toronto client needed 18 machines before Black Friday. Through our phased production system, we shipped units weekly from October. Their warehouse never exceeded 60% capacity. Want to calculate your ideal order cycle? Send throughput requirements via WhatsApp for a customized plan.

Where to Confidently Buy Pallet Stretch Wrapping Machines?

Fraudulent suppliers plague Alibaba. Fake certifications cause costly border rejections. We built trust through transparency.

Buy pallet stretch wrapping machines directly from manufacturers like us with live factory tours. We provide material test reports and recorded acceptance tests. CE, ISO certificates ship with every machine.

Verifying Supplier Credibility: Critical Steps

Certification Authentication Process

- Document Verification

- Check authentic CE numbers at ec.europa.eu

- Verify ISO certificates on certification body sites

- Production Audits

- Third-party inspections (SGS/BV)

- Video walkthroughs of welding stations

Material Quality Assurance

| Key components we test: | Part | Test | Standard | |

|---|---|---|---|---|

| Turntable | Load endurance | 125% rated capacity | ||

| Film carriage | Continuous cycle | 100+ hours non-stop | ||

| PLC | Voltage fluctuation | ±15% variation test |

A Montreal buyer discovered faked certificates from a "factory" last month. We immediately shared our steel mill certificates with holograms. Such forged documents caused him $28,000 in prior losses. For genuine documentation kits, contact our team today.

Which Pallet Wrapping Machine for Sale Fits Your Operation?

Oversized machines waste space. Underpowered units cause bottlenecks. Matching specs to needs is crucial.

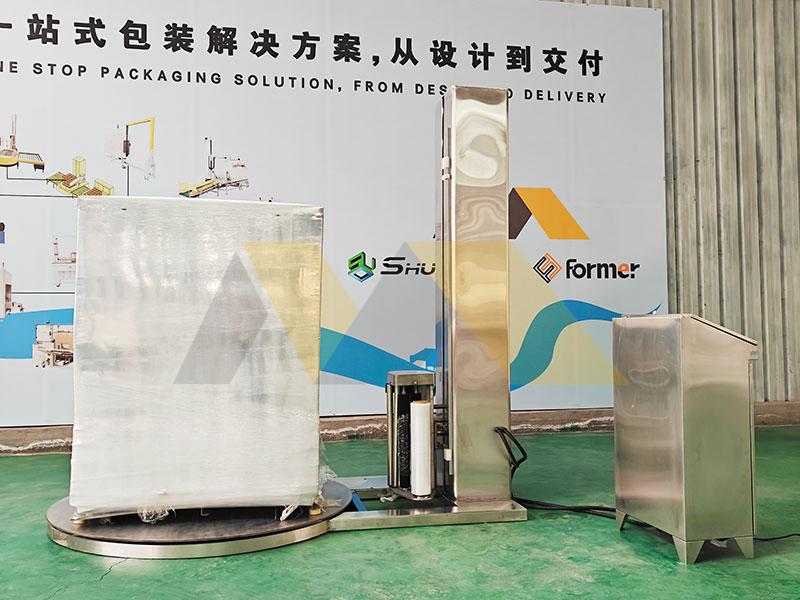

The ideal pallet wrapping machine for sale depends on pallet dimensions and hourly volume. Our engineering team analyzes your facility layout to recommend semi-auto or automatic models with optimized footprints.

Selecting the Perfect Machine Configuration

Capacity Matching Guide

| ^^^model-selection | Throughput | Pallet Size | Recommended Type | Cycle Time |

|---|---|---|---|---|

| <20/hr | 40"x48" | Semi-automatic | 90 sec | |

| 20-40/hr | 48"x48" | Automatic | 45 sec | |

| 40+/hr | 48"x60" | Robotic arm | 30 sec |

^^^

Customization Opportunities

We can modify:

- Height requirements (up to 100 inches)

- Temperature resistance (-20°F to 140°F)

- Film pre-stretch (250%-300%)

A New Jersey client chose modular upgrades instead of replacement. We retrofitted conveyor interfaces to connect with their existing AS/RS system, saving 65% versus new purchases. Send your packaging video for free suitability analysis via WhatsApp.

What Determines Pallet Stretch Wrapping Machine Price?

Hidden fees surprise buyers. Unqualified "discount" machines fail prematurely. We provide transparent pricing breakdowns.

Pallet stretch wrapping machine price varies by these factors: automation level ($2,300-$18,000), motor power (+$500 per HP increase), and engineering complexity. Customized options typically add 10% to base costs.

Detailed Pricing Structure Analysis

Core Components Cost Breakdown

| Component | Standard | Premium | Cost Impact |

|---|---|---|---|

| Frame | Carbon steel | Stainless steel | +$1,200 |

| Drive | AC motor | Servo motor | +$3,800 |

| Control | Basic PLC | Touchscreen HMI | +$900 |

Overhead Influence Factors

- Export Compliance (documentation preparation)

- Packaging Specifications (storm-ready crates)

- Power Adaptation (110V ↔ 220V conversion)

Base model prices don’t include North American electrical mods. Last week, we prevented a Toronto client’s $1,200 surprise charge by recommending integrated CE-compliant motors. Our quotes categorize expenses clearly. Request itemized quotation with savings tips: message us today.

Conclusion

Choosing Chinese manufacturers brings quality at competitive prices when verifying credentials. Let’s discuss a custom solution for your distribution needs. Connect for details: WhatsApp us.