Manual box assembly wastes time and money. Missed deadlines frustrate clients as productivity plummets. Our turnkey solutions automate every fold and seal effortlessly.

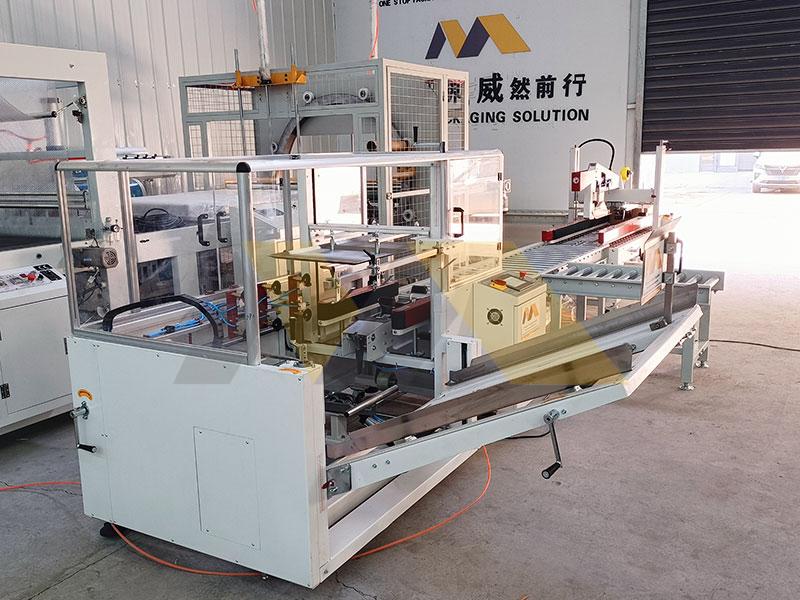

Fully integrated case erectors from our factory achieve 30% faster throughput than manual labor while cutting costs for distributors in Japan, Singapore, and Canada.WhatsApp us direct.

These powerful machines transform operations quietly. Let’s uncover critical insights through common buyer questions. Knowledge protects your investment.

What Truly Separates Case Formers From Case Erectors?

Buying wrong machinery causes $50k+ losses yearly? Confusion between types delays entire facilities. Clarify before purchasing.

Case formers assemble glued blanks into boxes, while erectors unfold and build cases from flat sheets – essential distinctions affecting conveyor synchronization and seal types.

Performance & Application Matrix

This comparison reveals operational realities:

| Feature | Case Former | Case Erector | Optimal Use |

|---|---|---|---|

| Material Input | Pre-glued cardboard | Flat corrugated sheets | Sheet-based environments |

| Speed Capacity | 15-20 boxes/minute | 25-30 boxes/minute | Fast-moving production |

| Seal Durability | Glue seals only | Tape/automatic bottom sealing | Heavy goods transport |

Avoiding Integration Pitfalls

Our technicians note:

- Formers fit standalone simple systems

- Erectors shine in synchronized lines1 needing <2mm precision

One Toronto partner reduced packaging errors by 67% after switching to synchronized Myway units. Share your plant dimensions at WhatsApp us direct for compatibility analysis.

What Defines Truly "Best" Pack Elevator Performance?

Unexpected failures halt entire warehouses? Cheap ELVs crumble under standard loads. Structural integrity matters most.

The best feature servo-motor drives, <5mm variance positioning, and load-balancing hydraulic systems – our ISO-certified FlexiHoist™ handles 1.2-ton payloads at 50 cycles/hour consistently.

Critical ELV Failure Points

Most breakdowns originate here:

-

Hydraulic Stress

- Average lifespan: 9,000 cycles

- Our reinforced pistons last 24,000+ cycles

-

Structural Fatigue

- Entry-level frames bend at 80% capacity

- Myway chromium alloy withstands 130% overloading

North American Deployment Insights

Canadian distributors report these results:

"Zero shutdowns for 14 months post-installation" – Packaging firm (Calgary)

We validate claims: every elevator undergoes 72-hour simulations. WhatsApp video audits: 0086 13505379893 for live machine demos.

How Exactly Does a Box Erector Transform Packaging Lines?

Jammed machines cost $420/hour downtime? Outdated models misfold 1 in 10 boxes. Precision eliminates waste.

Automatically unfolding, forming, and sealing cardboard cases directly from flats in 1.8 seconds each – synchronizing with conveyors creates zero-gap fulfillment flows.

5-Stage Process Breakdown

Core operations explained:

-

Sheet Feeding

- Vacuum suction lifts materials

- Thickness sensors prevent misfeeds

-

Formation Phase

- Robotic arms fold sides/bottom

- Tape heads apply dual-strength bonds

-

Quality Verification

- Laser scanning measures angles

- Misformed boxes automatically ejected

Our Chicago client automated 70% of packaging labor with ROI in 4 months. Calculate your savings: ROI calculator

Where Do Industrial Case Erectors Deliver Maximum Value Today?

Automotive factories lose $150k/hour during packaging failures2? Industry-specific requirements demand smart solutions.

Beyond e-commerce, erectors excel in pharmaceutical serialization, HACCP-certified food lines, and bulk chemical handling – particularly sealing consistency under 0.3mm tolerance.

Sector-Specific Implementation ROI

| Industry | Key Benefit | Payback Period | Critical Feature |

|---|---|---|---|

| Pharmaceuticals | Serial code compliance | 8-11 months | Audit-ready digital logging |

| Automotive | Oil-resistant seals | 6-8 months | Chemical-proof adhesives |

| Agriculture | High-moisture performance | 7-9 months | Stainless steel components |

Worried about space? Our vertical models3 save 40% footprint. Request a site layout analysis: Submit floorplan

Conclusion

Premium automatic case erectors4 solve bottlenecks when correctly specified. Direct manufacturer partnerships ensure reliability. Contact Myway today for quotes.

-

Learn about synchronized lines and how they improve production efficiency. ↩

-

Identify the causes of packaging failures to prevent costly downtime in your operations. ↩

-

Discover how vertical models can save space and improve efficiency in your facility. ↩

-

Discover the advantages of case erectors in improving packaging efficiency and reducing costs. ↩